- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Haixu

-

Model Number:

-

macrogrit

-

Usage:

-

abrasives media

-

color:

-

black

-

shape:

-

grain

-

Moh's hardness:

-

9.2-9.5

-

sample:

-

free

Quick Details

-

Type:

-

blasting media

-

Abrasive Grain Sizes:

-

F8-F220

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Haixu

-

Model Number:

-

macrogrit

-

Usage:

-

abrasives media

-

color:

-

black

-

shape:

-

grain

-

Moh's hardness:

-

9.2-9.5

-

sample:

-

free

Manufactuer offer products

15 Years manufacturing and export experiences

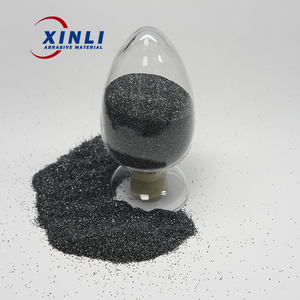

Silicon carbide particle blasting grit granite sand

F-grit F12-F2000

P-grit P12-P2000

Purity of sic is 98% standard

Scientific and accurate grit classification based on latest standard of GB and FEPA

Sufficient acid washing and less impurity

Contact person---Young Yang,cellphone--008613526810975,skype--young.yang36

Black Silicon Carbide particle brief introduce

Black Silicon Carbide particle is produced in a high temperature electric resistance-type furnace from a mixture of quartz sand and petroleum coke.

The hardness of black silicon carbide particle is greater than fused alumina but less than synthetic diamond.

Black silicon carbide's mechancial intensity is greater than fused alumina, but is brittle and very sharp.

Black silicon carbide particle has some electrical and heat conductivity.

Black silicon carbide particle is typically used for machining or finishing cast iron ,non-ferrous metals, stone, leather, rubber, and other materials where sharp cutting characteristics are important.

Black Silicon Carbide particle is also used widely as a refractory material or metallurgical additive. More detailed specifications can be supplied on your request.

Black silicon carbide's chemical specifications

|

Grit Size |

SiC |

FC |

Fe2O3 |

|

F12-F90 |

98.50 |

<0.20 |

0.60 |

|

F100-F150 |

98.50 |

<0.30 |

0.80 |

|

F180-F220 |

97.00 |

<0.30 |

1.20 |

|

F230-F400 |

96.00 |

<0.40 |

1.20 |

|

F500-F800 |

95.00 |

<0.40 |

1.20 |

|

F1000-F1200 |

93.00 |

<0.50 |

1.20 |

|

P12-P90 |

98.50 |

<0.20 |

0.60 |

|

P100-P150 |

98.00 |

<0.30 |

0.80 |

|

P180-P220 |

97.00 |

<0.30 |

1.20 |

|

P230-P500 |

96.00 |

<0.40 |

1.20 |

|

P600-P1500 |

95.00 |

<0.40 |

1.20 |

|

P2000-P2500 |

93.00 |

<0.50 |

1.20 |

Black Silicon Carbide physical index

|

Melting point |

2600 °C |

||

|

Hardness |

moh's 9.2 |

||

|

Bulk density |

1.38g/cm3 |

||

|

True density |

3.20-3.25g/cm3 |

||

Black silicon carbide's Application

F12-F14 ,use for sandblasting,rust removal,snagging,heavy duty grinding of steel ingot,leather,salt,floor boards.

F14-F30 ,use for casting play burr,cutting billet and steel tube,flat kibbling,steel ingot grinding,marble grinding,or as refractory material.

F30-F60 ,use for surface abrasion,outside&surface grinding,centerless grinding,tool grinding of quenching or no-quenching steel profiles,copper or other hard metal.

F60-F100 ,use for precision grinding, cutter sharpening,gear grinding,etc.

F100-F240 ,use for cutter sharpening,rough grinding,precision grinding,thread grinding.

F280-F600 ,use for precision grinding&thread grinding of instrument and matter an gear products.

F600-F2000 ,super-precision polishing,mirror polishing,surface lapping,etc.

P-git,P12-P2500,used for coated abrasives products,outstanding advantages compared to F-grit is the More concentrade grit distribution of the basic grain,narrow grain span than F-grit

Our Advantages

- Black silicon carbide macrogrit has SIC content 98% min

- we passed the certification of ISO9001:2000,and Equipped full line of test method.

- The laboratory is certified by government Inspection Bureau, that assures its quality stability.

- All products will be supplied according to customers different requirement.

- Brilliant produce&supply&delivery ability

- Flexible price policy

-