- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

YUGONG

-

Voltage:

-

380V 50Hz

-

Dimension(L*W*H):

-

As per model

-

Weight:

-

10 kg, 8600kg

-

Marketing Type:

-

Hot Product 2023

-

Max. width of cutting:

-

1400mm

-

Max diameter of material:

-

1400mm

-

Min. width of cutting:

-

50mm

-

Length of cutting:

-

20-400mm

-

Speed:

-

10-180times/min

-

Precision:

-

±0.2mm

-

Total power:

-

17kw

-

good:

-

Automatic tension control system

-

wahtsa..app:

-

0086-15515682190

Quick Details

-

Type:

-

Pulping Equipment

-

Production Capacity:

-

350 m/min

-

Max. workable width:

-

1200mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

YUGONG

-

Voltage:

-

380V 50Hz

-

Dimension(L*W*H):

-

As per model

-

Weight:

-

10 kg, 8600kg

-

Marketing Type:

-

Hot Product 2023

-

Max. width of cutting:

-

1400mm

-

Max diameter of material:

-

1400mm

-

Min. width of cutting:

-

50mm

-

Length of cutting:

-

20-400mm

-

Speed:

-

10-180times/min

-

Precision:

-

±0.2mm

-

Total power:

-

17kw

-

good:

-

Automatic tension control system

-

wahtsa..app:

-

0086-15515682190

Product Description

Why don't

contact me?

1. Provide most suitable machine model

2. Provide the most suitable construction plan

3. Get the latest discounts on purchases!

Note: Scan WhatsApp QR code

1. Open WhatsApp and tap Settings.

2. Tap the QR code icon displayed next to your name.

3. Click Scan > OK.

4. Hold the device and scan it at the top of the QR code.

5. Click Add Contact.

6. Open wealth~

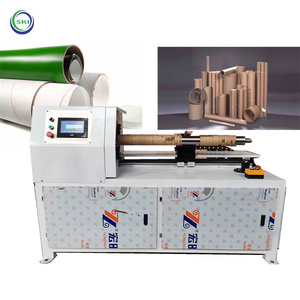

Specification

|

Model

|

YGA4-1100

|

YGA4-1400

|

|

Max. width of cutting

|

1100mm

|

1400mm

|

|

Max diameter of material

|

∅1400mm

|

∅1400mm

|

|

Min. width of cutting

|

50mm

|

50mm

|

|

Length of cutting

|

20-400mm

|

20-400mm

|

|

Speed

|

10-180times/min

|

10-180times/min

|

|

Precision

|

±0.2mm

|

±0.2mm

|

|

Total power

|

15kw

|

17kw

|

|

Weight

|

8000kg

|

8600kg

|

|

Overall diamension (LxWxH)

|

15200x1950x2550mm

|

15200x2200x2550mm

|

1, It adopts PLC touch screen control, servo motor for controlling constant-length cutting.

2, It adopts pneumatic, photoelectric sensor for controlling transmission system, with photo, electric, gas together, it has the functions of easy operation, high precision, good stability, low noise.

3, This machine has the functions of the frequency converter timing device, automatic counting, stop working by alarm magnetic powder tension control, can cut vertically, adopt blower to get rid of waste.

4, This machine can be with 1 roll. 2 rolls. 4 rolls loading system.

3, This machine has the functions of the frequency converter timing device, automatic counting, stop working by alarm magnetic powder tension control, can cut vertically, adopt blower to get rid of waste.

4, This machine can be with 1 roll. 2 rolls. 4 rolls loading system.

This machine suitable for Cutting all kinds of office paper, high-gloss paper, and paper-plastic composite packaging materials such as roll cutting.

1.The machine adopts PLC touch screen control, servo motor control fixed length cut.

2.Transmission system using pneumatic, photoelectric sensors and other centralized control, the machine collecting light.

Electric. Gas integration, easy operation, high cutting accuracy, mechanical stability, low noise and other advantages.

3.Motor frequency control, automatic counting, alarm parking, magnetic powder tension control. Longitudinal multistage cut, waste edge automatically removed by the fan.

4.Multi-roll at the same time horizontal and Vertical cut.

1.The machine adopts PLC touch screen control, servo motor control fixed length cut.

2.Transmission system using pneumatic, photoelectric sensors and other centralized control, the machine collecting light.

Electric. Gas integration, easy operation, high cutting accuracy, mechanical stability, low noise and other advantages.

3.Motor frequency control, automatic counting, alarm parking, magnetic powder tension control. Longitudinal multistage cut, waste edge automatically removed by the fan.

4.Multi-roll at the same time horizontal and Vertical cut.

Performance and Characteristics:

* Adopts pneumatic automatic materials loading system with much easy operation and convenience.

* Adopts down-up recurrent cutting with orderly finished products and without water caltrop;meantime, it can be used for

horizontal cutting and vertical cutting at one time.

* It adopts servo motor for controlling constant-length cutting.

* It adopts computer control, contact screen operation.

* It adopts pneumatic, displacement sensor for controlling transmission system, with photoelectric, gas together, it has the

function of easy operation, high precision, good stability, low noise.

* This machine has the function of the frequency converter timing device, automatic counting, stop working by alarm ,magnetic

.powder tension control, can be vertically, adopt blower fan to get rid of waste.

* It has the functions of high-precision of cutting, high speed,etc . pneumatic structure combined with computer control be

adopted for transmission section ,making it become much more steady operation.

* It has the function of automatic stacking which is in order . Photoelectric auto tracing subtense system

* Adopts pneumatic automatic materials loading system with much easy operation and convenience.

* Adopts down-up recurrent cutting with orderly finished products and without water caltrop;meantime, it can be used for

horizontal cutting and vertical cutting at one time.

* It adopts servo motor for controlling constant-length cutting.

* It adopts computer control, contact screen operation.

* It adopts pneumatic, displacement sensor for controlling transmission system, with photoelectric, gas together, it has the

function of easy operation, high precision, good stability, low noise.

* This machine has the function of the frequency converter timing device, automatic counting, stop working by alarm ,magnetic

.powder tension control, can be vertically, adopt blower fan to get rid of waste.

* It has the functions of high-precision of cutting, high speed,etc . pneumatic structure combined with computer control be

adopted for transmission section ,making it become much more steady operation.

* It has the function of automatic stacking which is in order . Photoelectric auto tracing subtense system

Our service

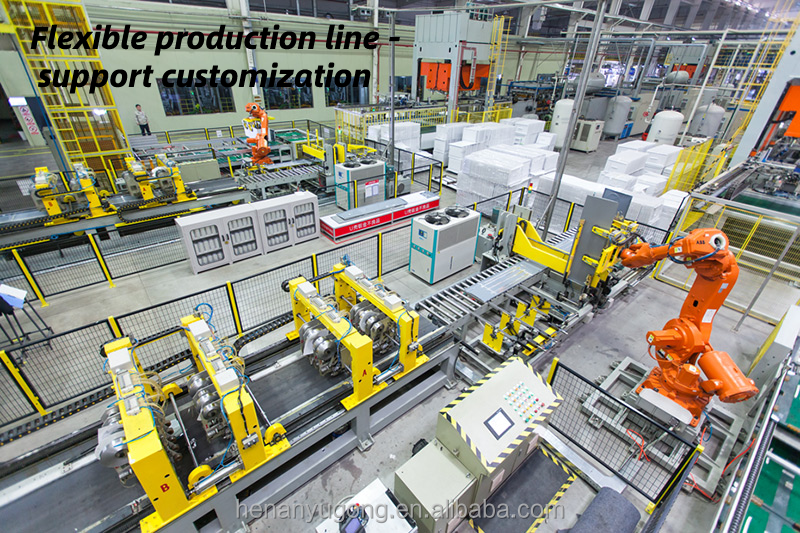

1.Support customization

Relying on our powerful flexible production line, we can give you the right to fully choose the mold, drive method, accessories upgrade, shell material, appearance color and Logo etc.

2.Extensive spare parts service

The spare parts warehouse of more than 50,000 square meters can meet the timely replacement and supplement of any wearing parts.

3.Support sea, land and air transportation

We can ship products to every corner of the world. If you need, we also support a series of tedious tasks such as customs clearance and tail end delivery.

Delivery

solid packaging

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

We also support air/sea/railway/automobile/bulk carrier, etc.;

Support from anywhere in China to anywhere in the world;

We can also help you to handle shipping/customs clearance/pay duties/delivery to your company and other services.

Our Company

Certification

We have passed CE, ISO, SGS certification! Better quality creates greater benefits for you!

Customer visit

We receive an average of 4 customers every week, visit and audit our factory, and negotiate business. There is a Chinese proverb:

It is always a pleasure to greet a friend from afar.

Factories and offices

More than 100,000 square meters of manufacturing and warehouse space More than 100 employees in the International Business Department.

FAQ & Contact

Q: I just started to enter these industries? Don't know what to do?

A: We will assist you to choose a cost-effective machine; we will provide assistance in purchasing raw materials, equipment debugging, and later technical guidance.

Q: How can I ship these machines to my company after purchase?

A: We have a stable and cooperative freight forwarder and have rich experience. We can be responsible for the whole process of transportation/customs declaration/customs clearance/transportation, and transport the goods to your company.

Q: Can you tell us about your service and support throughout the process?

A: I think selling a machine is just the start of our partnership

1.We will provide technical solutions, product selection guidance, and related supporting equipment support before sales

(For example, to help you identify hot-selling products in the market to determine machine selection)

2.Provide regular feedback on manufacturing progress in production Pictures or videos

3.Provide machine testing after sale; free accessories; stable packaging; product shipping to your factory , customs clearance and shipping services we can also cover;

4.During production: continuous debugging of the machine; raw material supply etc.

Hot Searches