- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

500 mm

-

Width of Working Table (mm):

-

400 mm

-

Dimension:

-

7000*4000*6150

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

MINAN

-

Weight (KG):

-

7800

-

Motor Power (kw):

-

74 kw

Quick Details

-

Machine Type:

-

Torsion Bar

-

Length of Working Table (mm):

-

6000

-

Slider Stroke (mm):

-

400 mm

-

Throat Depth (mm):

-

500 mm

-

Width of Working Table (mm):

-

400 mm

-

Dimension:

-

7000*4000*6150

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

MINAN

-

Weight (KG):

-

7800

-

Motor Power (kw):

-

74 kw

Products Description

W67K series economical CNC hydraulic plate bending machine is the company's indepen- dent research and development of products. Mature product structure,stable and reliable performance nd quality, so as to achieve accurate, energy-saving, quiet bending processing, widely used in the sheet metal processing industry. According to the requirements of users,different shapes of molds can be selected.

Details Images

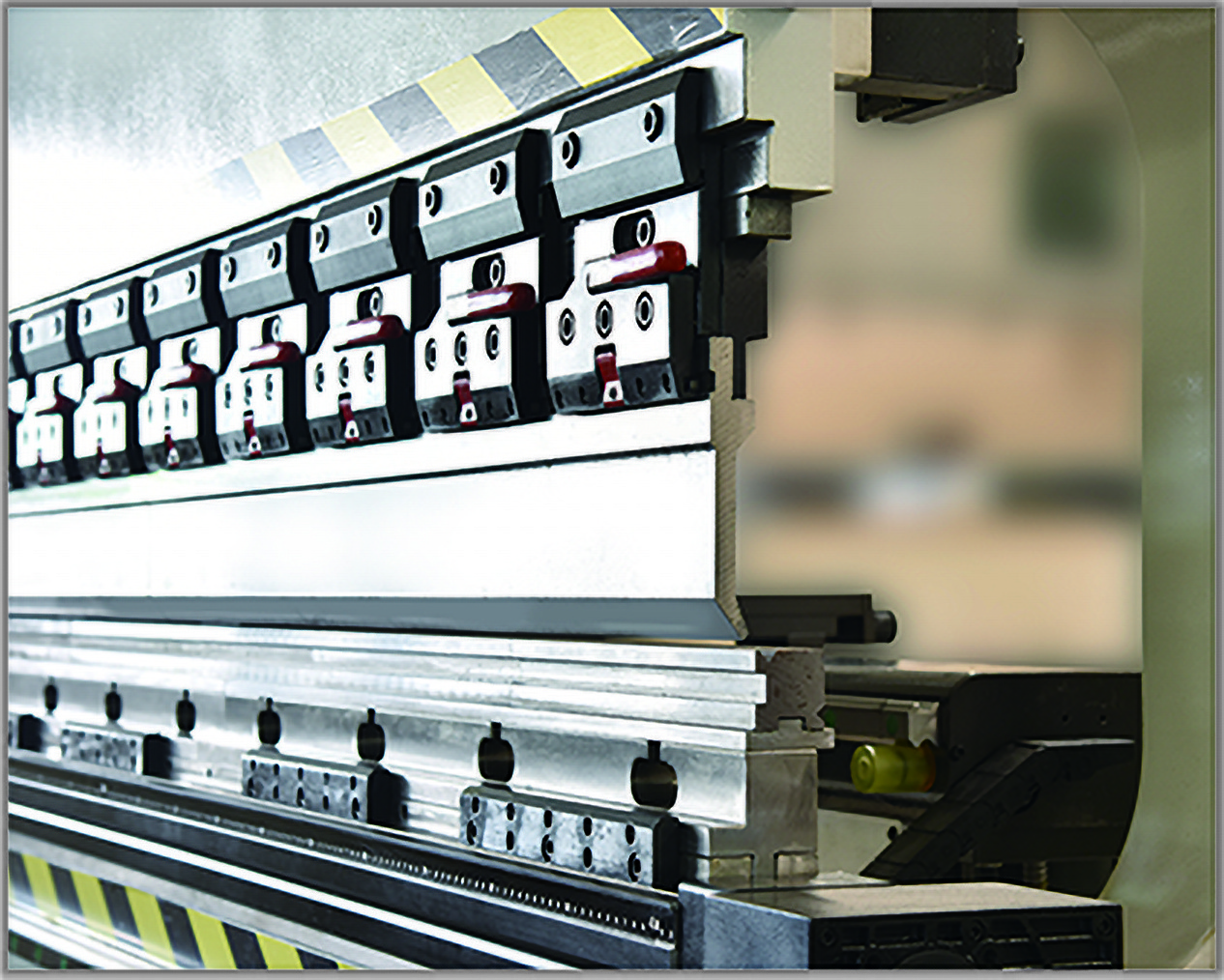

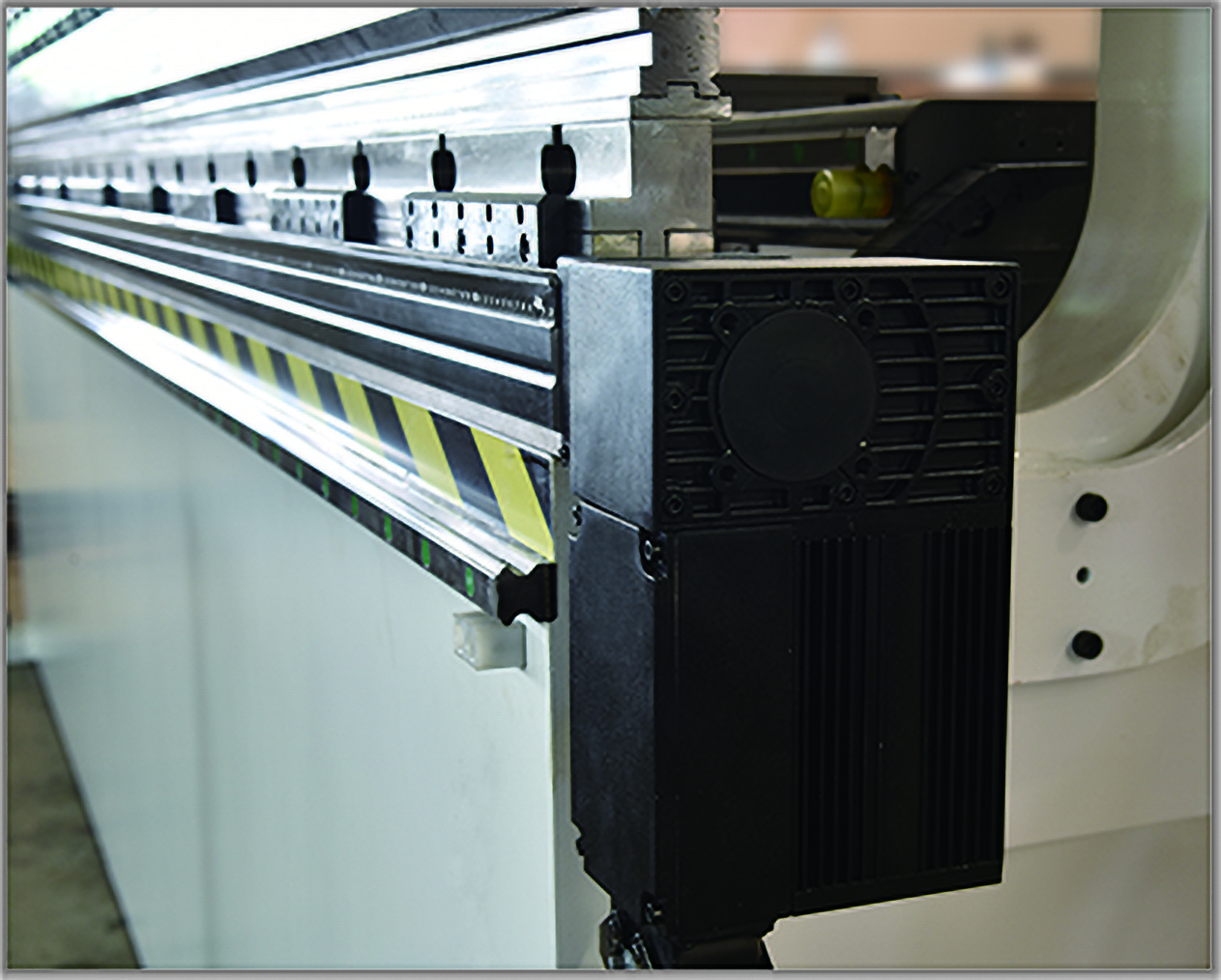

Imported ball screw, linear guide rail

Beam adjustment

PLC electrical system

Major performance characteristics

Adopt man-machine interface, Chinese display, digital input, no code simple and easy to use; Key opera- tion, parameter screen, programming screen;

It has multi-step programming function, realizes multi-step automatic operation, completes one-time machining of multi-step parts, and improves production power;

Automatic detection and diagnosis in operation engineering,alarm prompt and processing;

The utility model has the functions of conceding and escaping materials, avoiding the interference between the rear material stopper and the work, reducing the abrasion and improving the positioning accuracy;

It has the function of power-off position memory, and protects the parameters, position and program on site;

The bending pressure can be set by the operator directly on the man-machine interface;

Prepare imported ball screws and linear guide rails to ensure the positioning accuracy of machine tool shaft

Product Paramenters

|

Type

|

|

800/60

|

|

|

Nominal pressure(KN)

|

|

8000

|

|

|

Bending width(mm)

|

|

6000

|

|

|

Column spacing(mm)

|

|

3150

|

|

|

Slide stroke(mm)

|

|

130

|

|

|

Slide adjustment distance(mm)

|

|

110

|

|

|

Distance between slider and workbench(mm)

|

|

310

|

|

|

Throat depth(mm)

|

|

500

|

|

|

Workbench width(mm)

|

|

400

|

|

|

Fast Forward speed(mm/s)

|

|

100

|

|

|

working speed(mm/s)

|

|

8

|

|

|

Return speed(mm/s)

|

|

70

|

|

|

Motor power(kW)

|

|

74

|

|

|

Backgauge stroke(mm)

|

|

600

|

|

|

Overallsize

|

Length

|

7000

|

|

|

|

Width

|

4000

|

|

|

|

Height

|

6150

|

|

Hot Searches