- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

216-823-5

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Wellmid

-

Model Number:

-

W-2015-1LB

-

Type:

-

Epoxy Adhesive

-

Net:

-

1LB

-

color after cured:

-

Green

-

Viscosity at 25°C:

-

Thixotropic

-

State:

-

Non-liquid

-

Working time:

-

4 hours

-

Cure condition:

-

Room + high temperature

-

Full strength at 100℃:

-

3 hours

-

Working temperature:

-

-60℃~ 120℃

Quick Details

-

CAS No.:

-

1675-54-3

-

Other Names:

-

W-2015-1LB

-

MF:

-

216-823-5

-

EINECS No.:

-

216-823-5

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Wellmid

-

Model Number:

-

W-2015-1LB

-

Type:

-

Epoxy Adhesive

-

Net:

-

1LB

-

color after cured:

-

Green

-

Viscosity at 25°C:

-

Thixotropic

-

State:

-

Non-liquid

-

Working time:

-

4 hours

-

Cure condition:

-

Room + high temperature

-

Full strength at 100℃:

-

3 hours

-

Working temperature:

-

-60℃~ 120℃

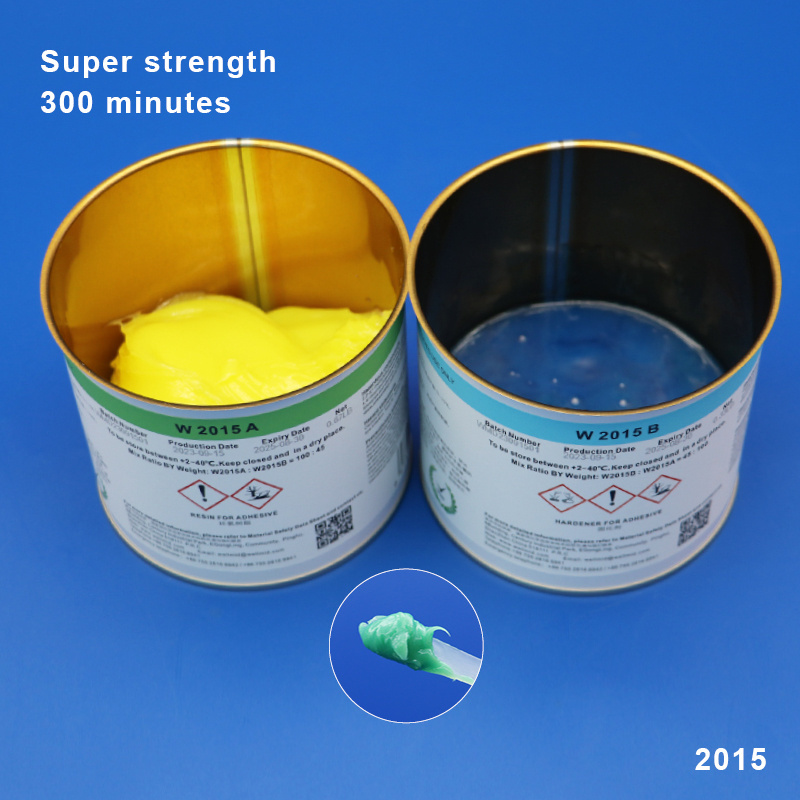

Two Component Caulking and Super Strength Epoxy Adhesive

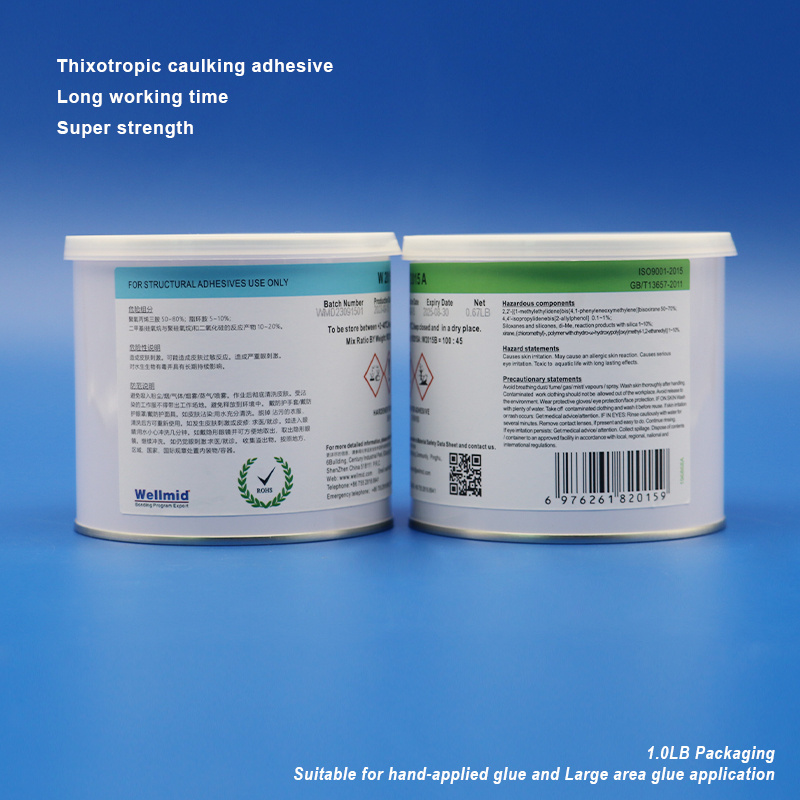

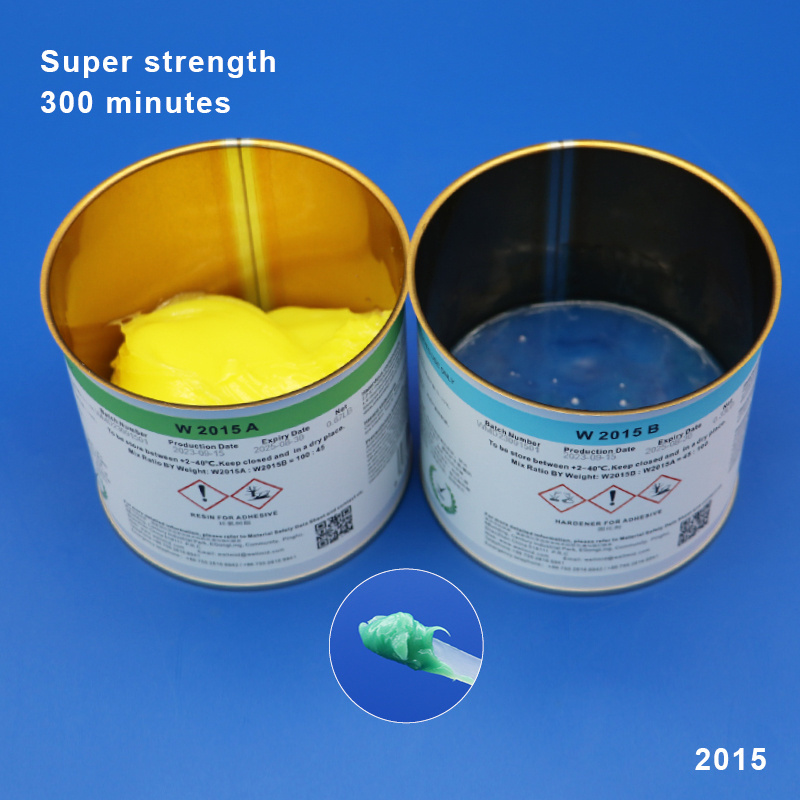

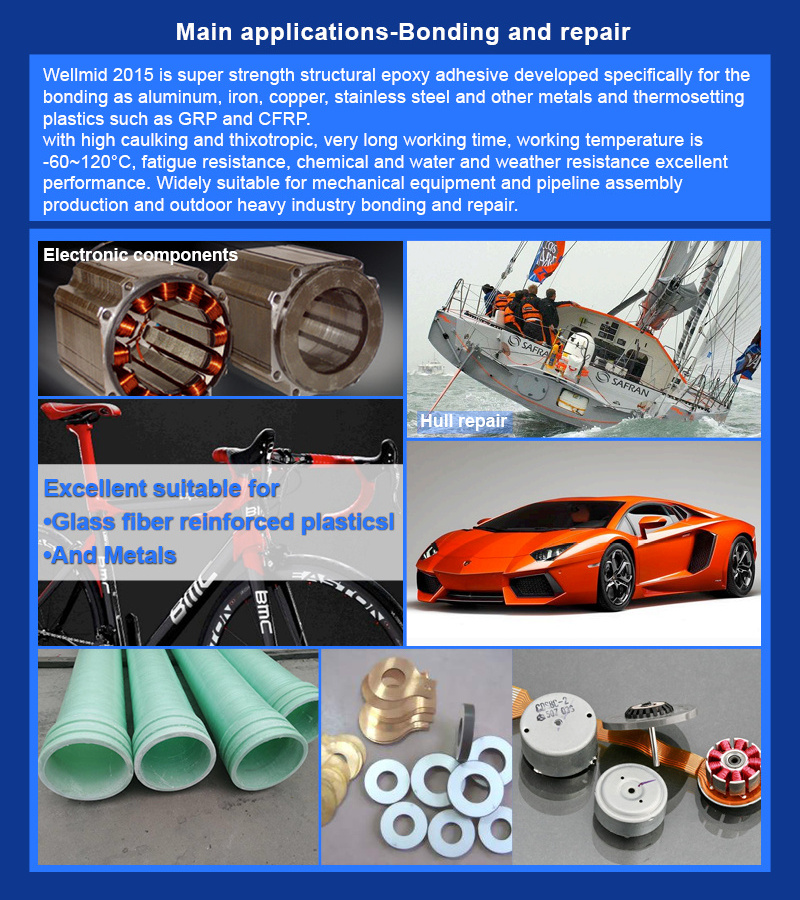

Wellmid 2015 is a two-component epoxy super strength structural adhesive developed specifically for the bonding as aluminum, iron, copper, stainless steel and other metals and thermosetting plastics such as GRP and CFRP. No solvent, no smell, with high caulking and thixotropic, very long working time, working temperature is -60~120°C, fatigue resistance, chemical and water and weather resistance excellent performance. Widely suitable for mechanical equipment and pipeline assembly production and outdoor heavy industry bonding and repair.

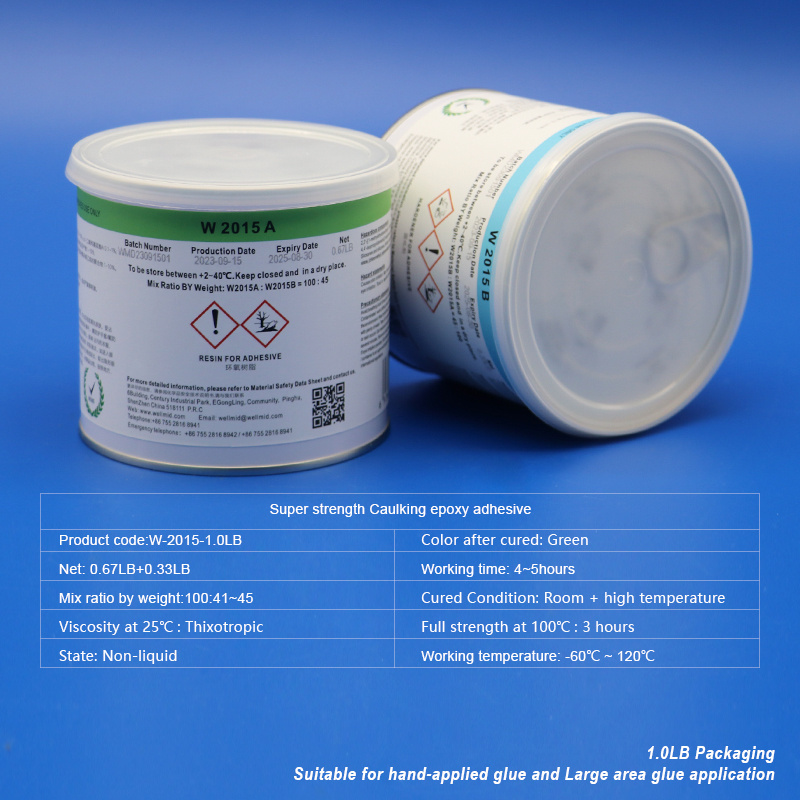

Product code: W-2015-1LB

Net: Resin313.1Grams + Hardener140.9Grams

Mix ratio by volume: 100:41~45

Viscosity at 25℃: Thixotropic

State: Non-liquid

Working time: 4~5hours

Cured Condition: Room + high temperature

Full strength at 100℃: 1~3 hours

Color after cured: Green

Working temperature: -60℃~ 120℃

Suitable for structural bonding under high dynamic load

Non-flowing thixotropic caulking adhesive, the filling reach 40mm

Very long working time, easy to large area construction

Can be bonded to most materials, especially glass fiber reinforced plasticsl and metal

Excellent weather, water and chemical resistance

More product Information please read TDS and SDS , Please don't hesitate to contact us.

1LB W 2015 Thixotropic Epoxy Adhesive Caulking and Bonding Metal and thermosetting plastics GRP CFRP Super Strength Green AB Glue.

Note: Wellmid 2015 can not be directly bonded to PE, PP, HDFE, PTFE.

If you need to bond these materials, Please contact us to recommend suitable glue.

1LB Tin can Packing, Suitable for hand-applied glue and Large area glue application.

Application 3 steps.

Wellmid 2015 is recommended that after curing at normal temperature for 8-24 hours, the temperature rises to 80°C ~120°C and curing again for 30 minutes ~3 hours.Or refer to the above table to select the curing temperature and curing time suitable for the production process to achieve the best performance of the product formulation design.

ODM For You

W2015 has various specifications . It can meet the amount of household use, industrial use and the amount that is convenient for you to test. You can choose the appropriate specification according to the use requirements.

Tin can packing: 2oz(56.7Grams) / 1Lb(454Grams) / 3kg Tin can sets.

W-2015-2OZ

W-2015-3KG

1.Where to buy Wellmid glue ?

Sign up for a free Alibaba membership and you can buy it right away.o

r leave a message and we'll give you the right guidance

2.What are my payment methods?

You can pay by Credit or Debit card online, or by wire transfer.Credit or debit card online payment processing time 1-2 hours.

The wire transfer processing time is 3-7 Business Days.

3.When is it safe to use what i've repaired or made?

All glues have a period over which the "bond strength" increases to its maximum - even super or instant glues.Check your pack for details.

4.How strong is glue?

The right glue, properly applied, will give you a permanent fix as strong as any mechanical device.

5.To be safe i used even more glue than was recommended but it still didn't work.why not?

Actually too much glue doesn't help and doesn't usually produce a neat finish.Also check whether you should be applying to one surface or both.Always follow the product instructions on your pack.

6.I'm worried about the effects of accidentally inhaling fumes.should i be?

All adhesives are safe when handled according to guidelines. It's always best to work in a well-ventilated area but there's no danger from fumes.

7.Are glues safe for my children to use?

Instant or rapid bond glues are best used under supervision for younger children but all glues are safe when handled according to Wellmid guidelines. There are glues recommended for art and craft materials like paper, cardboard and fabrics.

8.Will the adhesive cure at low temperature ?

Wellmid adhesives are not recommended to be used at temperatures below 10°C.The curing times given on the packs are for a temperature of 23°C, if the temperature is lower, the cure will take longer.

9.Are there any adhesive suitable to bond pp, pe or ptfe ?

Yes.Wellmid 3010 is capable of bonded this plastics

PP = Polypropylene

PE = Polyethylene

PTFE = Polytetrafluorethylene

10.How do i remove cured residues of Wellmid Glue ?

Uncured residues can be removed using warm water and soap water.

Cured residue or exuded adhesive may be destroyed by immersion in commercial paint strippers, such as Nitromors or Multistrip.NOTE : Care should be taken in using the chemicals given above since they may be hazardous to handle or inflammable, and may also attack the substrate.

11.The surface of the cured Wellmid epoxy adhesive remains sticky, is it fully cured ?

If the adhesive remains sticky on the surface left open to air, it does not necessarily means that the adhesive is not fully cured.Under certain conditions, the hardener can react with carbon dioxide in the air and leave a sticky layer on the surface of the cured adhesive.Normally this layer can be easily removed with a wet cloth.

12.The Wellmid epoxy adhesive does not cure.

Problems with our epoxy adhesives are often caused by a wrong mix ratio between the resin and the hardener, if you use tubes, the quantity of resin and hardener is sometimes difficult to evaluate.If you use syringes, we recommend to extract the small amount of air which may be present in the syringe before extruding the product.

Which glue is right for you?

The following table shows the performance of some of our products, you can choose the right products according to your needs.For your better browsing, please download pictures to browse. You can also contact us to obtain Excel documents for better product selection.

1. About the chemical, color and mix ratio of glue.

2.

About the viscosity, state, pot life and cure condition of glue.

3. About the tack free time, cure time, operating temperature and glass transition temperature of glue.

4. About the strength and resistance of glue.

5. About the bonding materials of glue.

6. About the packing specification of glue.