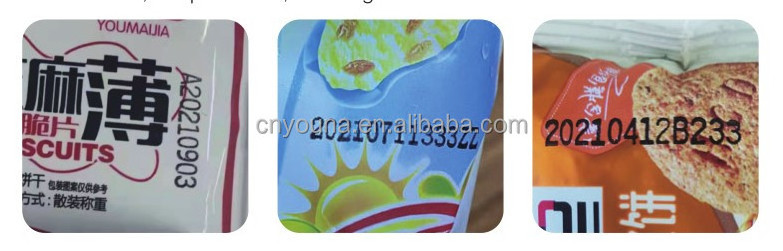

The hot ink roll is used for ink roll coding machine, sealing machine, and 380F coding machine to print the production date, batch number and other digital and text identification on various flexible packaging film such as paper, PP film, PE film, PVC ect. The ink roll is able to print at high speed, instant drying,good adhesion, anti friction, no pollution, and high resolution.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

youna

-

Model Number:

-

Dye Ink

-

Product name:

-

Pigment Ink

-

Color:

-

CMYK

-

Ink Type:

-

Environmental Eco Solvent Ink

-

Feature:

-

100% Safe

-

Application:

-

Package Printing

-

Certificate:

-

ISO

-

Packing:

-

Carton Packing

-

Keyword:

-

roll Ink

-

Quality:

-

Excellent

-

MOQ:

-

1 Piece

Quick Details

-

Type:

-

solid ink

-

Printing Type:

-

Transfer Printing

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

youna

-

Model Number:

-

Dye Ink

-

Product name:

-

Pigment Ink

-

Color:

-

CMYK

-

Ink Type:

-

Environmental Eco Solvent Ink

-

Feature:

-

100% Safe

-

Application:

-

Package Printing

-

Certificate:

-

ISO

-

Packing:

-

Carton Packing

-

Keyword:

-

roll Ink

-

Quality:

-

Excellent

-

MOQ:

-

1 Piece

Products Description

printing machine hot solid ink roll ink roller

printing machine hot solid ink roll ink roller

T he initial temperature is 100℃ (middle temperature),120℃ (high TEMP)(Increasing gradually).

1. When in use, install the ink roller to the main shaft ofcoding machine,turn on the power,set the temperature to100 ℃(middleTEMP),120 ℃ (high TEMP),pre-heat 15-20 mins, The ink roller can be printed after melting completely,increase 10 ℃per 50000 prints,the highest temperature is 150 ℃ (middle TEMP),160℃ (high TEMP).

2.The contact depth between the character and the ink roller is 0.5-2mm, The contact depth between the support wheel and the ink roller is 0.1-0.3mm(as legend shows).

3. Lower the temperature of coding machine to the initialtemperature before replace new ink roller.

1. When in use, install the ink roller to the main shaft ofcoding machine,turn on the power,set the temperature to100 ℃(middleTEMP),120 ℃ (high TEMP),pre-heat 15-20 mins, The ink roller can be printed after melting completely,increase 10 ℃per 50000 prints,the highest temperature is 150 ℃ (middle TEMP),160℃ (high TEMP).

2.The contact depth between the character and the ink roller is 0.5-2mm, The contact depth between the support wheel and the ink roller is 0.1-0.3mm(as legend shows).

3. Lower the temperature of coding machine to the initialtemperature before replace new ink roller.

|

Model

|

middle temp ink roller

|

high temp ink roller

|

|

|

Service temperature

|

100--150°C

|

120-160°C

|

|

|

Features |

easy to use, high definition, quick drying,anti-scratch,pollution-free,non-toxic, many times of printing, low cost, good adhesion.

|

Strong adhesion, anti - freezing.

|

|

|

Application

|

Suitable for printing letters and numbers on flexible packaging materials such as paper, PP film, PE film, PET film, PVC etc.

|

|

|

|

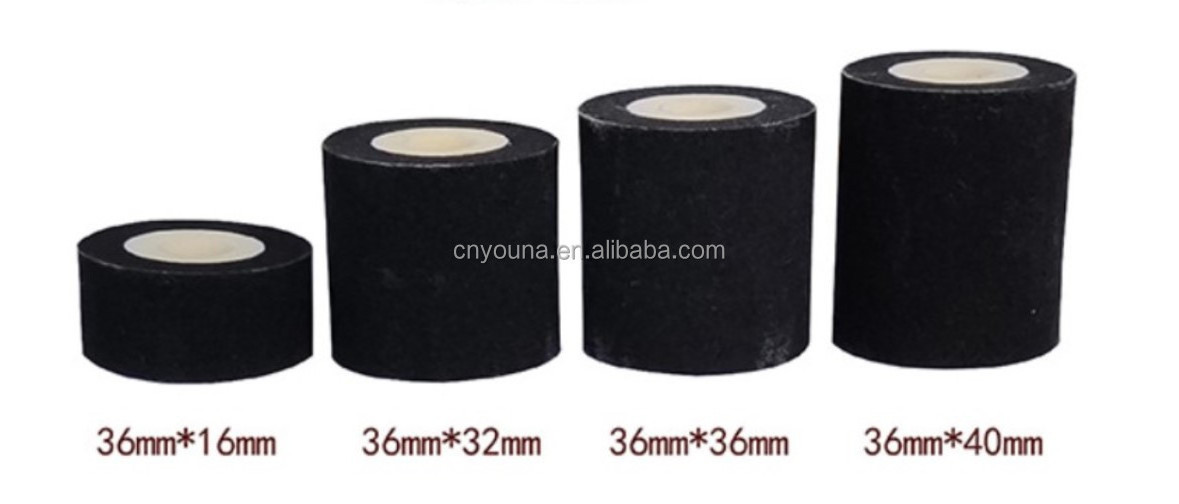

Specification

|

36mm"10mm

36mm*16mm 36mm*32mm 36mm*36mm 36mm"40mm 40mm*40mm 48mm*55mm 48mm*60mm |

|

|

|

Color

|

black red white yellow blue green grey orange

|

|

|

|

Others

|

Support to customize different colors and specifications

|

|

|

Product shows

Factory corner

Hot Searches