This equipment is applied for drying, sterilizing and depyrogenation of washed vials, ampoules and the other containers, the

tunnel is divided into three processing zones which are of preheating zone, heating zone and cooling zone. According to the

requirement the air cooling and water cooling as be in options. All the fabric material in line with GMP guideline.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≤±0.5%(base one water)

-

Voltage:

-

220V 380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

delaney

-

Dimension(L*W*H):

-

14000*2300*2100

-

Weight:

-

9000 KG

-

Product name:

-

cartridge filling machine

-

filling accuracy:

-

≤0.5%

-

filling speed:

-

100bpm max can be 500bpm

-

capping rate:

-

≥99.5%

-

aseptic or not:

-

aseptic

-

bottle type:

-

vial 2ml 5ml 10ml-500ml

-

Filling range:

-

0.01ml-500ml

-

Material:

-

stainless steel 304

Quick Details

-

Machinery Capacity:

-

12000BPH

-

Packaging Material:

-

Wood

-

Filling Material:

-

Water

-

Filling Accuracy:

-

≤±0.5%(base one water)

-

Voltage:

-

220V 380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

delaney

-

Dimension(L*W*H):

-

14000*2300*2100

-

Weight:

-

9000 KG

-

Product name:

-

cartridge filling machine

-

filling accuracy:

-

≤0.5%

-

filling speed:

-

100bpm max can be 500bpm

-

capping rate:

-

≥99.5%

-

aseptic or not:

-

aseptic

-

bottle type:

-

vial 2ml 5ml 10ml-500ml

-

Filling range:

-

0.01ml-500ml

-

Material:

-

stainless steel 304

Factory manufacture

aseptic half-plug lyophilized powder freeze-dried powder filling

cartridge filling machine

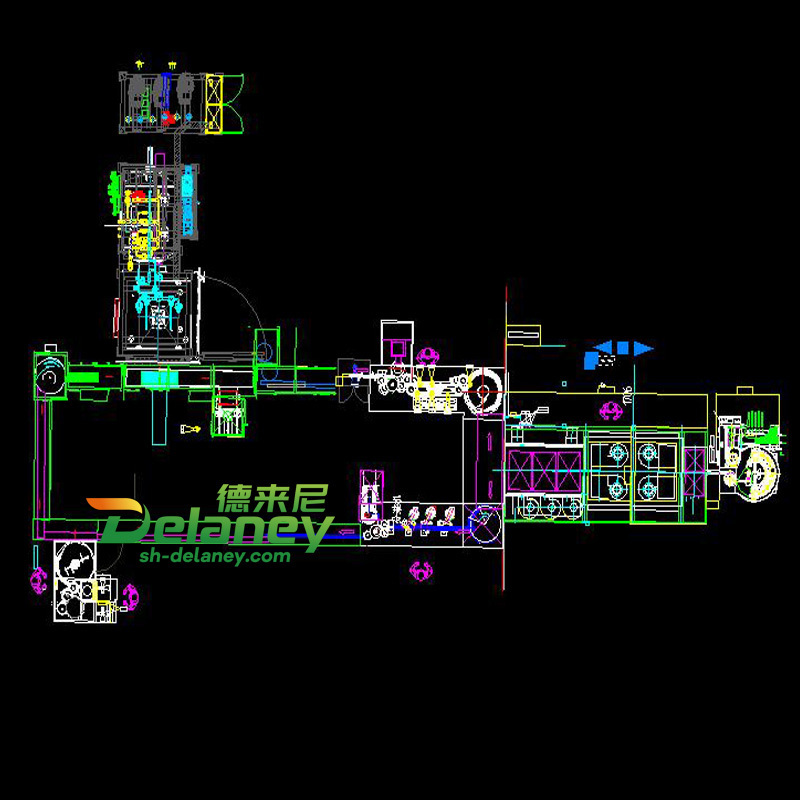

The machine's key parts purchased from well-known manufactures adopt latest control system. Stable running of the line, easier,operation,low noise, no pollution to production environment. The entire line is in compliance with GMP guideline. RABS could be provided optionally.The line is applicable to 2ml-500ml vials and the speed is max.30000 vials/hour.

Washing machine description

Machine Features

■ Wide applicable container sizes from 2-500ml, Less sizepart changing

■ Ultrasonic treatment in the same time

■ High washing efficiency

■ Machine hood lift-up automatically(Option)

■ Glass debris discharge device

■ Media insufficient alarm function

■ Container contact material in line with FDA guideline

■ Wide applicable container sizes from 2-500ml, Less sizepart changing

■ Ultrasonic treatment in the same time

■ High washing efficiency

■ Machine hood lift-up automatically(Option)

■ Glass debris discharge device

■ Media insufficient alarm function

■ Container contact material in line with FDA guideline

|

Breakage

|

≤0.01%

|

|

WFI Pressure

|

>0.3Mpa

|

|

WFI temperatuere

|

40-60℃

|

|

WFI consumption

|

0.3m³/hr

|

|

RW pressure

|

>0.3Mpa

|

|

Power

|

3 P 380V

|

|

Machine dimension

|

1300 1528 1400mm

|

|

Infeeding height

|

1000mm

|

|

Machine weight

|

Approx.1600kg

|

Heat circulation tunnel sterilization

Filling and capping machine

The machine is a continuous linear multi-function filling device for handling of the aseptic injectables liquid under cleaning

environment with a “V” shape conveyor vial transferring from the infeeding to the outfeeding. This conveyor belt with no sizepart

change for handling of vial sizes from 2ml to 100ml.

environment with a “V” shape conveyor vial transferring from the infeeding to the outfeeding. This conveyor belt with no sizepart

change for handling of vial sizes from 2ml to 100ml.

FAQ

Q: Do you have CE certificate ?

A: yes of course

Q: How long is your delivery time?

A:20-40 days after receiving the confirmation.

Q: What is your terms of payment ?

A:30% by T / T as the deposit for confirming the order; 70% balance shipment

Q: How to install and adjust the machine ?

A: We provide online guides, videos and user manual to help customers. In some places, we have engineers.

Q:whats you advantage?

A:More than 20 years of experience, one stop solution, providing 2d/3d drawings.

A:20-40 days after receiving the confirmation.

Q: What is your terms of payment ?

A:30% by T / T as the deposit for confirming the order; 70% balance shipment

Q: How to install and adjust the machine ?

A: We provide online guides, videos and user manual to help customers. In some places, we have engineers.

Q:whats you advantage?

A:More than 20 years of experience, one stop solution, providing 2d/3d drawings.

Hot Searches