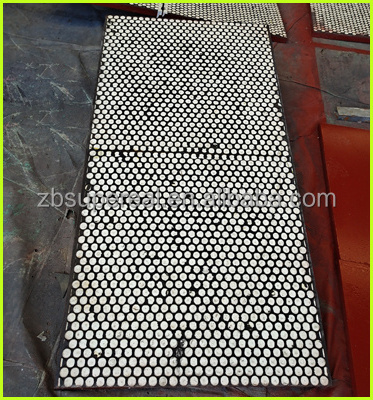

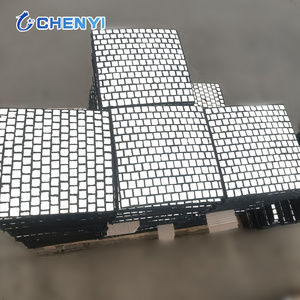

1) Good Abrasion Resistance

As the wear surface, the alumina ceramic is 9 Mohs hardness

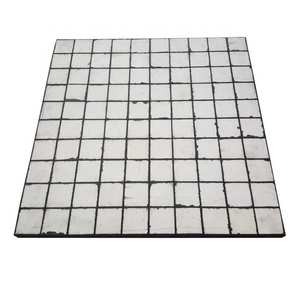

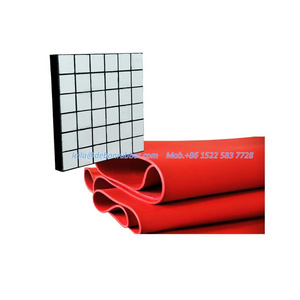

2) Good Thermal Stability and Excellent Corrosion Resistance

The ceramic liners are high purity alumina tiles or tubes which have unique chemical properties of wonderful acid and alkali resistance.

3) Light Weight

The density is 3.63 g/cm³,which is only half of the steel to reduce the load of equipment largely

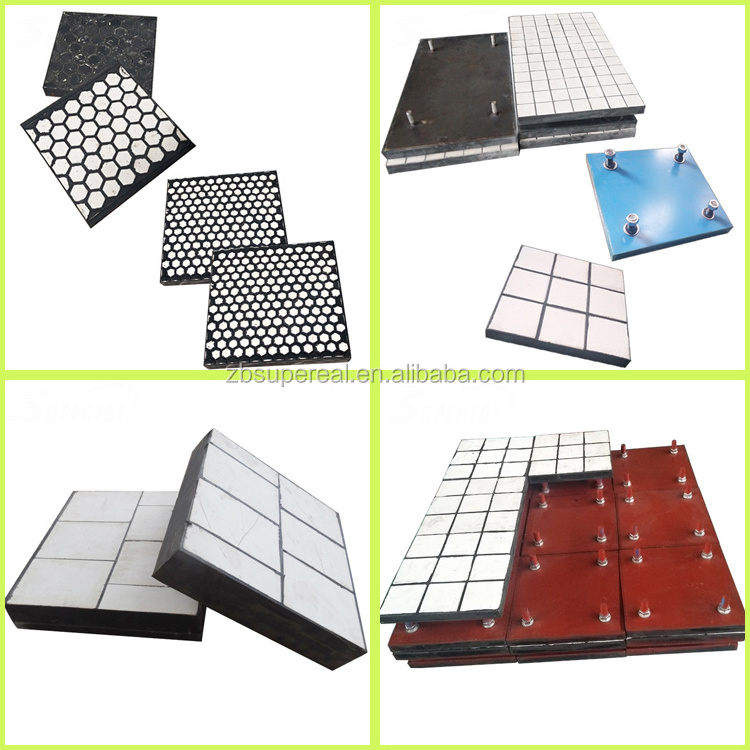

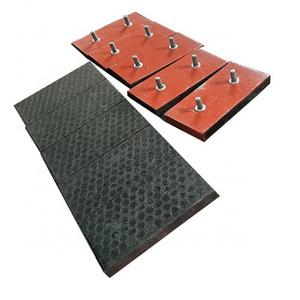

4) Easy and fast to fix on site

Welding, flange, flexible joint are available for fix with the equipment.

As the wear surface, the alumina ceramic is 9 Mohs hardness

2) Good Thermal Stability and Excellent Corrosion Resistance

The ceramic liners are high purity alumina tiles or tubes which have unique chemical properties of wonderful acid and alkali resistance.

3) Light Weight

The density is 3.63 g/cm³,which is only half of the steel to reduce the load of equipment largely

4) Easy and fast to fix on site

Welding, flange, flexible joint are available for fix with the equipment.