- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

3year

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

naidi

-

Model Number:

-

AWS E316-16 e316l-16

-

Operating Current:

-

DC AC

-

Application:

-

welding of synthetic fiber and other equipments

-

Product Name:

-

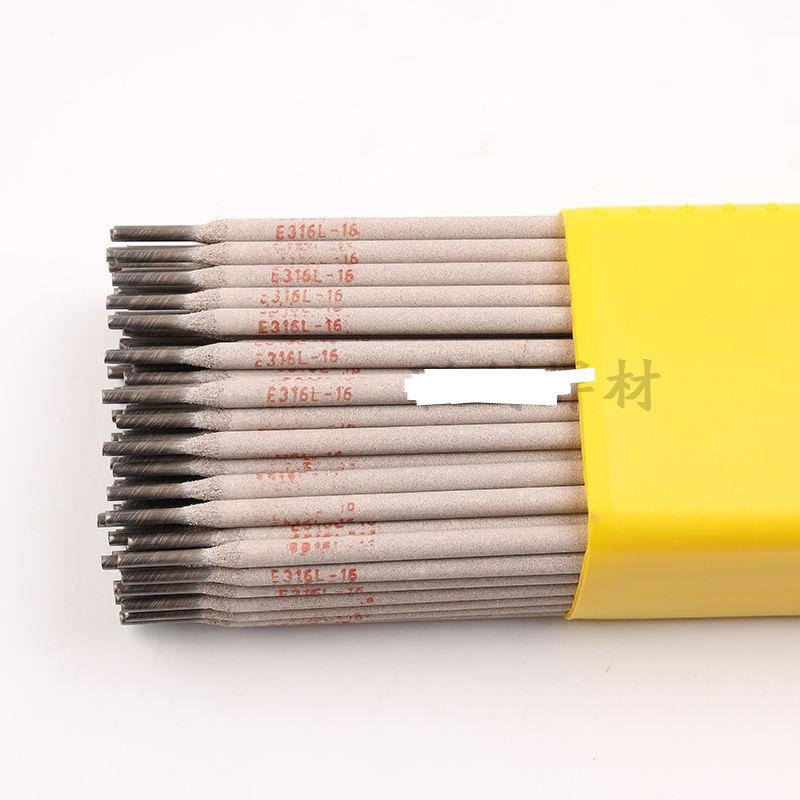

A5.4 E316L-16 stainless steel electrode

-

Type:

-

Titanium calcium type coating

-

Usages:

-

welding of synthetic fiber and other equipments

-

Advantage:

-

anticorrosion,crack resisitance

-

Color:

-

White-grey

-

Sample:

-

Sample Free

-

Standard:

-

aws e316l

-

Certification:

-

ISO9001 ISO14001 BV

-

PACKING:

-

20kg/carton ,5kg/inner box

-

OEM:

-

Accept OEM

Quick Details

-

Material:

-

Stainless steel

-

Welding Current:

-

40-230A

-

Operating Temperature:

-

Standard Temperature

-

Warranty:

-

3year

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

naidi

-

Model Number:

-

AWS E316-16 e316l-16

-

Operating Current:

-

DC AC

-

Application:

-

welding of synthetic fiber and other equipments

-

Product Name:

-

A5.4 E316L-16 stainless steel electrode

-

Type:

-

Titanium calcium type coating

-

Usages:

-

welding of synthetic fiber and other equipments

-

Advantage:

-

anticorrosion,crack resisitance

-

Color:

-

White-grey

-

Sample:

-

Sample Free

-

Standard:

-

aws e316l

-

Certification:

-

ISO9001 ISO14001 BV

-

PACKING:

-

20kg/carton ,5kg/inner box

-

OEM:

-

Accept OEM

A5.4 E316L-16 stainless steel electrode

GB/T 983 E316L-16

A5.4 E316L-16

Introduction:

A022 is a kind of Titanium calcium type coating with ultra-low carbon Cr18Ni12Mo2 stainless steel electrode. Carbon

content of deposited metal is less than or equal to 0.04%. It has excellent heat resistance, the corrosion resistance, the

crack resistance and the porosity resistance. Good operation performance and high strength coating. AC/DC both can

be applied.

Uses:

Used for welding of synthetic fiber and other equipments and the same type of stainless steel structure, In addition, it is

applied to weld the steel that cannot be processed with thermal treatment, such as Chromium stainless steel, clad steel,

dissimilar steel, etc.

Chemical Composition (%)

|

Chemical Composition |

C |

Mn |

Si |

S |

P |

Cr |

Ni |

Mo |

Cu |

|

Guarantee Value |

≤0.04 |

≤ 0.50~2.50 |

1.00 |

≤ 0.030 |

≤ 0.040 |

17.0~20.0 |

11.0~14.0 |

2.0~3.0 |

≤ 0.75 |

|

General Result |

0.025 |

1.20 |

0.60 |

0.007 |

0.021 |

19.05 |

11.60 |

2.45 |

0.038 |

Mechanical Properties of Deposited Metal

|

Test Item |

Rm(N/mm 2 ) |

A (%) |

|

Guarantee Value |

≥490 |

≥ 25 |

|

General Result |

570 |

46 |

Reference Current ((AC OR DC + )

|

Diameter (mm) |

φ2.0 |

φ2.5 |

φ3.2 |

φ4.0 |

φ5.0 |

|

Welding Current (Amps) |

40~80 |

50~100 |

70~130 |

100~160 |

140~200 |

Notes:

1.The electrode must be preheated at the temperature of 300°C for 1 hour. Preheat the rod whenever it is used

2.As Preferred DC power supply, electric current should not be high.