- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

1500 sets per years

-

Power:

-

2200

-

Dimension(L*W*H):

-

1500mm*1500mm*1300mm

-

After-sales Service Provided:

-

Field maintenance and repair service

-

Product name:

-

Aluminum Alloy Hydraulic Corner Crimping Machine

-

Usage:

-

aluminium window combining work

-

Control System:

-

Schneider System

-

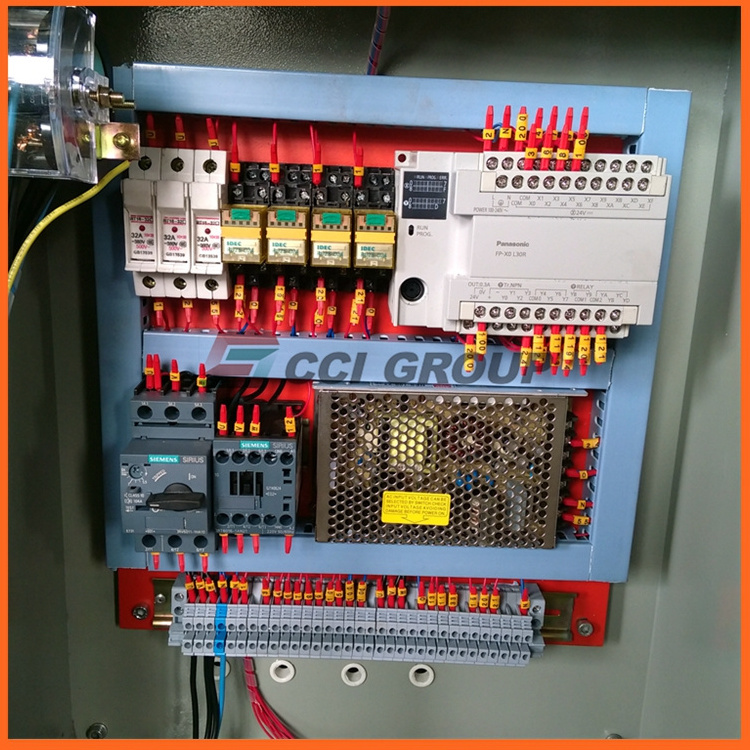

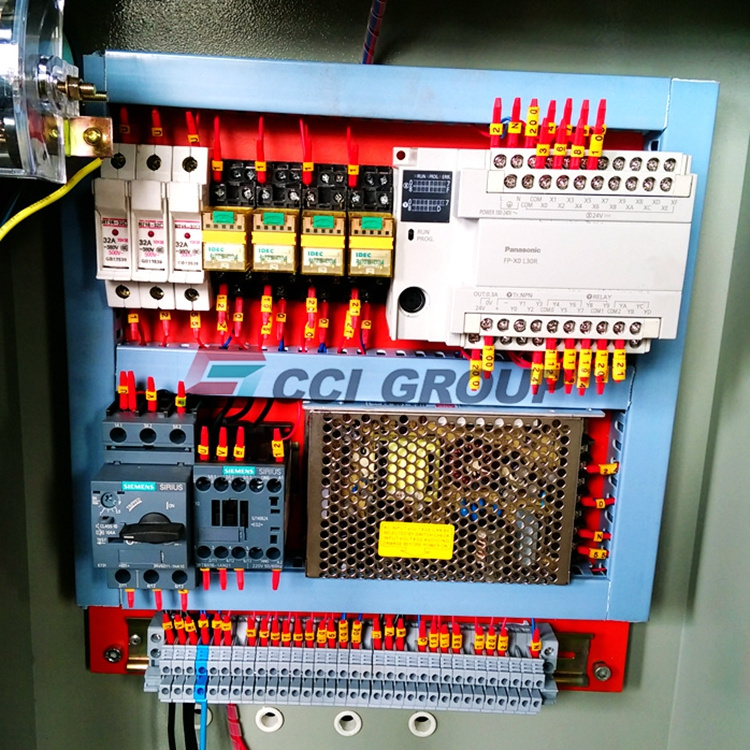

Electric Parts:

-

Schneider/ Siemens

-

Max. Window Combining Height:

-

150mm

-

Power supply:

-

380V 50Hz 2.5Kw

-

Hydraulic system pressure:

-

15Mpa

-

Overall dimension:

-

1500mm*1500mm*1300mm

Quick Details

-

Brand Name:

-

CCI

-

Voltage:

-

380V 220V

-

Weight:

-

600 kg, 600Kg

-

Production Capacity:

-

1500 sets per years

-

Power:

-

2200

-

Dimension(L*W*H):

-

1500mm*1500mm*1300mm

-

After-sales Service Provided:

-

Field maintenance and repair service

-

Product name:

-

Aluminum Alloy Hydraulic Corner Crimping Machine

-

Usage:

-

aluminium window combining work

-

Control System:

-

Schneider System

-

Electric Parts:

-

Schneider/ Siemens

-

Max. Window Combining Height:

-

150mm

-

Power supply:

-

380V 50Hz 2.5Kw

-

Hydraulic system pressure:

-

15Mpa

-

Overall dimension:

-

1500mm*1500mm*1300mm

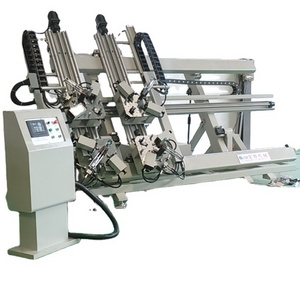

aluminum corner crimping machine Name:

LZJ04-160A Updated Trade Assurance Aluminum Alloy Hydraulic Corner Crimping Machine with Panasonic System

aluminum corner crimping machine Model: LZJ04-160A

aluminum corner crimping machine Function :

- LZJ04-160 is the advanced Aluminum Alloy Hydraulic Corner Crimping Machine .

- Used for large section profile connection of 90°angle structure of aluminum curtain walls and doors & windows.The max. aluminum window corner crimping height is 150mm.

- This Aluminum Alloy Hydraulic Corner Crimping Machine adopts France Schneider control system and France Schneider/ German Siemens electric Parts.

- Aluminum Alloy Hydraulic Corner Crimping Machine new linkage structure makes corner-assembling synchronous.

- Inner location device has elevating device.

- Two sets hydraulic system. Left and right punching heads feed synchronous to avoid deforming in corner-assembling procedure to make window corner connection more solid.

- This machine uses Japan SMC pneumatic valve and EASUN pneumatic cylinder .

- Synchronously feeding structure makes the adjustment simple and easy.

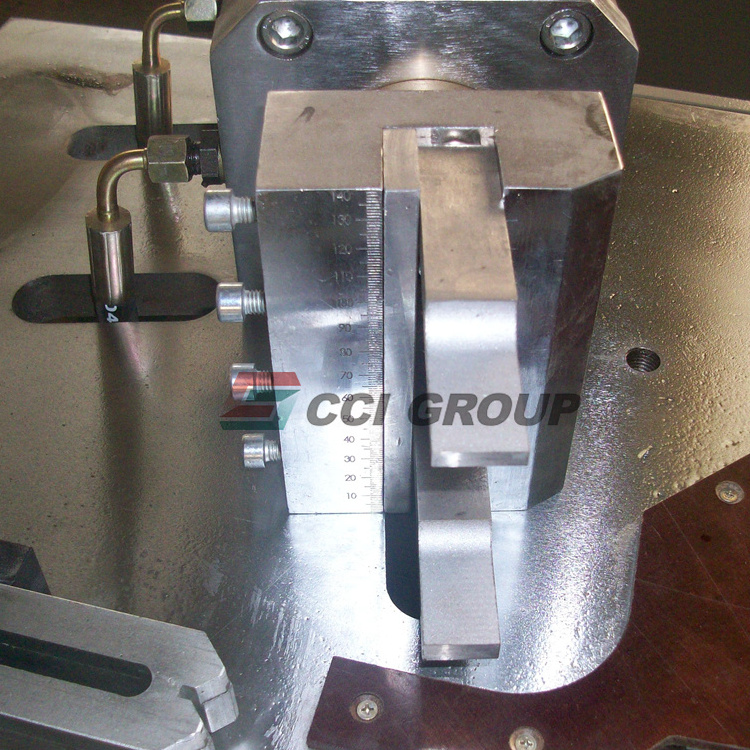

- The blades can be adjusted up and down relatively by the threads.

- It can be equipped with single-blade multi ple point tool s, making the corner-forming more reliable, the work more efficient, the manufactures more precision and the quality more excellent.

- Aluminum Alloy Hydraulic Corner Crimping Machine is much useful for shaped aluminum window door frame and sash corner.

| Series No. | Technical Item | Technical Parameters |

| 1 | Power Supply | 380V 50Hz/ 220V 60Hz |

| 2 | Power Rate | 2.5Kw |

| 3 | Rated Pressure | 15Mpa |

| 4 | Crimping Tool Specification | 3/5/8mm |

| 5 | Max. Crimping Height | 150mm |

| 6 | Over Dimension | 1850*1680*1210mm |

| 7 | Total Amount | 600Kg |

Aluminum Alloy Hydraulic Corner Crimping Machine

Aluminum Alloy Hydraulic Corner Crimping Machine

Processing Effects

Aluminum Alloy Hydraulic Corner Crimping Machine

F rance Schneider/ Pansonic Control System & Schneider/ Siemens Electric Parts

The package and shipping i s our follow-up item of our factory maketing work and prelude item of our factory after service work.

+ Our factory pay more attention to our machine package and shipping.

+ Package type: Wooden Case/Wooden Pallet/ Carton.We do not suggest using the plastic cover only on our machines.

+ Shipping type: Sea transportation and Express transportation. We do not suggest using the land transportation.

Our senior engineer is available to travel aboard, help the installation, maintenance and training staff.

We have our own spare parts warehouse for window door machines and insulating glass machines.

We can reply for every customers within 24 hours.

By offering this support, we make sure the cutomer start the business smoothly, to realise win-win cooperation.

CCI always looking for long term cooperaion, not one time deal.