Shandong Xinhao Tire Material Co., Ltd. is mainly engaged in the wholesale: truck and bus tires at home and abroad, as well as the import and export business of steel cord, bead wire, carbon black, tire cord fabric, hose wire and other tire raw materials.

1.Steel cord: Annual output of 150 thousand tons, has passed ISO9001, ISO14001, OHSAS18000" three in one "comprehensive management system certification.

2. Bead wire: Annual output of 100 thousand tons, hose wire 30 thousand tons.

3. Carbon black: 7 new wet carbon black process production lines, with a capacity of 200thousand tons, have passed the international quality management system certification, environmental management system certification, and occupational health and safety management system certification.

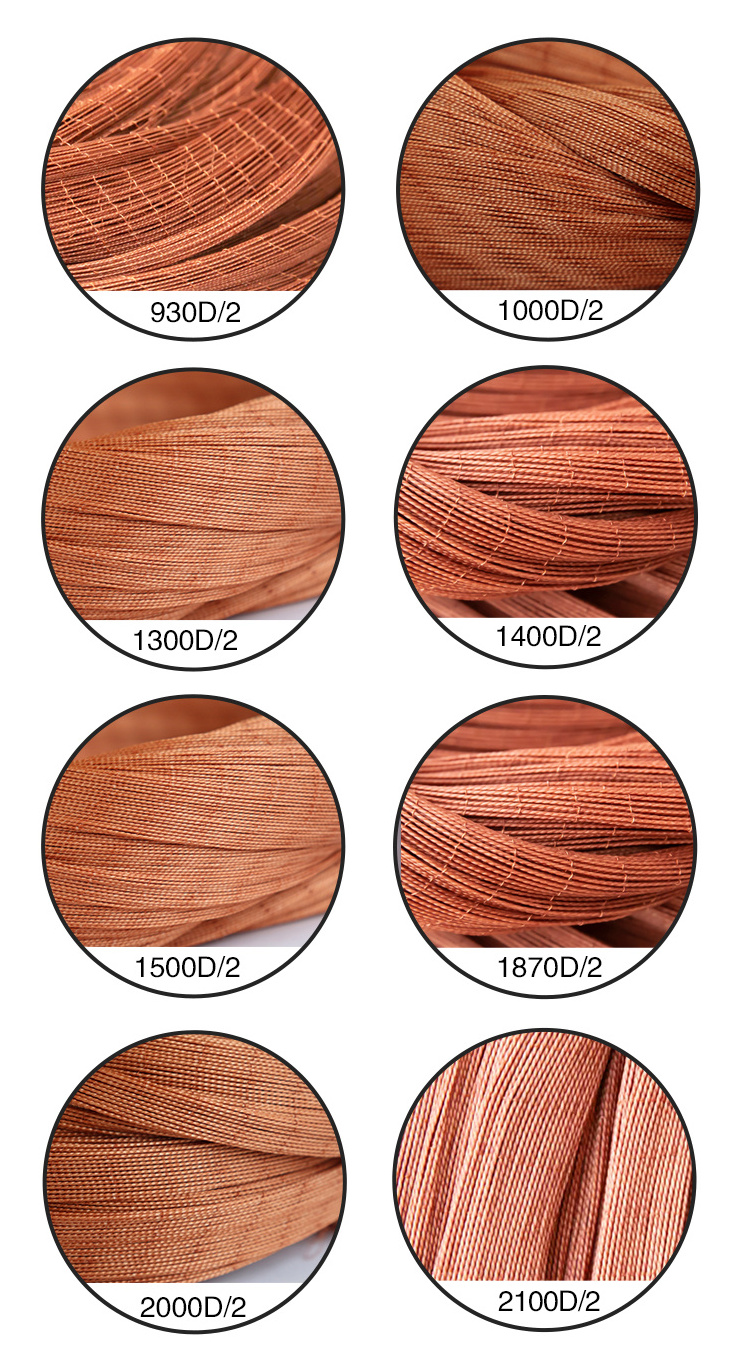

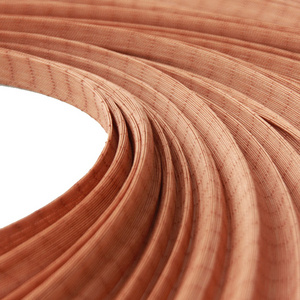

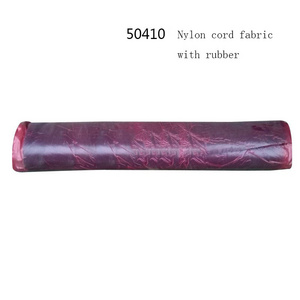

4. Cord fabric: The main products are Nylon Tyre Cord Fabric, Polyester Tyre Cord Fabric, Polyamide Yarns, polyester industrial yarn and so on.