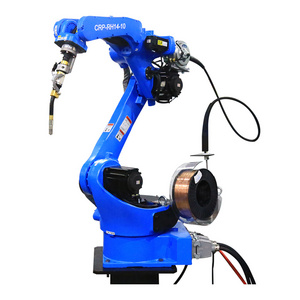

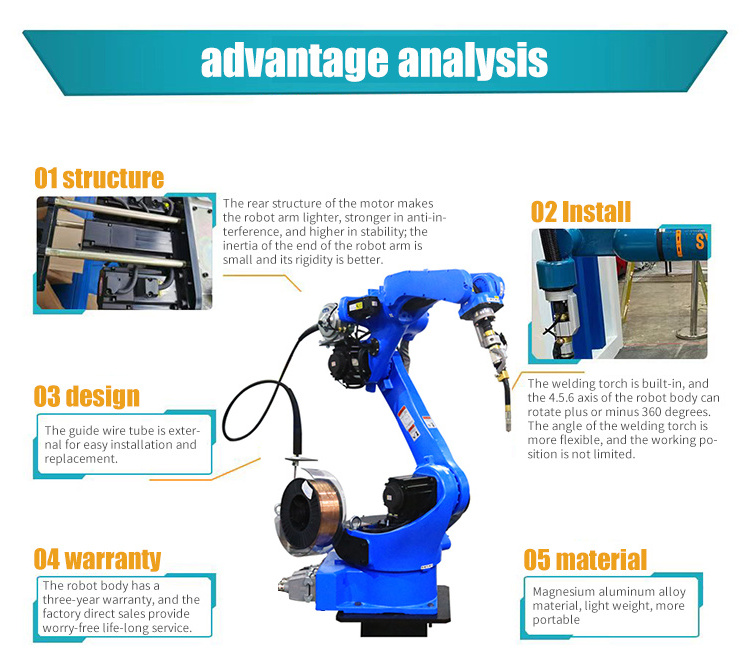

Through the seamless combination of welding process packages and ecological components, users can quickly realize various welding applications. The process package supports the full range of CR collaborative robots and is compatible with a variety of mainstream welding machines. Users can choose accessories according to their needs to build their own welding systems.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

3 phase 380v or customized

-

Current:

-

350A

-

Rated Capacity:

-

Depends

-

Rated Duty Cycle:

-

60%

-

Dimensions:

-

Depends

-

Use:

-

Welding

-

Product name:

-

Automatic Welding Robot

-

Application:

-

Rework BGA

-

Function:

-

Welding Steel Tube

-

Name:

-

Beam Automatic Welding Machine

-

Keyword:

-

Welding Robot China

-

After Warranty Service:

-

Online Support Video Technical Support

-

Type:

-

Automatic Control

-

Feature:

-

High Efficiency Automatic Welding Robot

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Rayman

-

Weight (KG):

-

500

-

Voltage:

-

3 phase 380v or customized

-

Current:

-

350A

-

Rated Capacity:

-

Depends

-

Rated Duty Cycle:

-

60%

-

Dimensions:

-

Depends

-

Use:

-

Welding

-

Product name:

-

Automatic Welding Robot

-

Application:

-

Rework BGA

-

Function:

-

Welding Steel Tube

-

Name:

-

Beam Automatic Welding Machine

-

Keyword:

-

Welding Robot China

-

After Warranty Service:

-

Online Support Video Technical Support

-

Type:

-

Automatic Control

-

Feature:

-

High Efficiency Automatic Welding Robot

Product Description

Diversified compatibility, suitable for a variety of mainstream welding machines

Diversified compatibility, suitable for a variety of mainstream welding machines

Through the seamless combination of welding process packages and ecological components, users can quickly realize various welding applications. The process package supports the full range of CR collaborative robots and is compatible with a variety of mainstream welding machines. Users can choose accessories according to their needs to build their own welding systems.

Graphical interface, 10 minutes to get started

Ease of use is the primary principle of our product design. Relying on the leading full-trajectory recurring drag teaching technology, users can drag the robotic arm to quickly generate points or trajectories, and then generate various required welding procedure. Easily complete operations such as welding machine type, welding parameter configuration, and teaching programming. Even ordinary people without editing foundation can learn it within 10 minutes.

Four arc swing modes to meet more welding scenarios

The welding process package provides a variety of swing arc welding modes such as triangle, spiral, trapezoid, and sine, which can effectively increase the width of the weld and meet the needs of more welding scenarios. In addition, the welding process voltage and current can be set according to the plate thickness and weld bead to obtain better welding quality.

All-round man-machine collaboration to ensure safety and efficiency

The welding robot provides a high-sensitivity collision detection function. When the robot or the end mechanism accidentally touches a person or an obstacle, the system will stop welding immediately, fully ensuring the safety of people and equipment. After shutdown, the staff can reset through the upper computer to quickly resume production. At the same time, the process package also has a dual-station reservation function. Through the preset welding program, one-click switching of the robot production station can effectively reduce the waiting time for machine downtime and realize efficient man-machine collaboration.

Customize various welding scenes

Support arc welding or laser welding, provide a variety of welding modes and algorithm support, users can customize according to different metal materials and application scenarios, whether it is carbon steel, stainless steel or copper or aluminum welding, whether it is straight line or arc Welding can keep the weld beautiful and not deformed.

Specification

|

item

|

value

|

|

Applicable Industries

|

Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Retail, Food Shop, Food & Beverage Shops, Advertising Company

|

|

Showroom Location

|

None

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

New Product

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

PLC, Gearbox, Motor

|

|

Condition

|

New

|

|

Place of Origin

|

China

|

|

|

Shandong

|

|

Brand Name

|

RM1210

|

|

Weight

|

300kg

|

|

Dimension(L*W*H)

|

1200mm

|

|

Power

|

6000

|

|

Warranty

|

1 Year

|

|

Weight (KG)

|

300kg

|

|

Product name

|

Robot Arm

|

|

Application

|

Industrial Automatic

|

|

Function

|

welding

|

|

Axis

|

6-axis

|

|

Keyword

|

6 Axes Welding Robotic Arm

|

|

Type

|

Fully Automatic

|

|

After Warranty Service

|

Online Engineer Support

|

|

Robot type

|

6 Axis Articulated Robot

|

|

Material

|

Aluminum Alloy

|

|

Technology

|

Robot Controller Technology

|

Packing & Delivery

Fumigation free wooden case

Hot Searches