- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Evenpack

-

Weight:

-

400 KG

-

Dimension(L*W*H):

-

2400*900*1800mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Function:

-

Cap lining machine

-

Liner material:

-

customized

-

Cap size:

-

Customized

-

Speed:

-

Customized

-

Certification:

-

CE

-

Marketing Type:

-

Popular

Quick Details

-

Voltage:

-

Customized

-

Power:

-

2kw

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Evenpack

-

Weight:

-

400 KG

-

Dimension(L*W*H):

-

2400*900*1800mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Function:

-

Cap lining machine

-

Liner material:

-

customized

-

Cap size:

-

Customized

-

Speed:

-

Customized

-

Certification:

-

CE

-

Marketing Type:

-

Popular

We customize lining/wadding/assembling machines for various kinds of caps/liners

( plastic caps, alumimum caps, plugs, rings, different kinds of liners...)

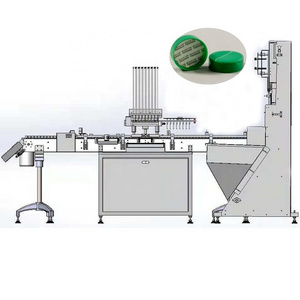

Cap lining machine cap wadding machine cap liner inserting putting machine by quality factory

Brief introduction:

| Machine name: |

Cap lining machine cap wadding machine cap liner inserting putting machine by quality factory |

| Function: | Cap liner inserting machine is for mass production, consisting of automatic caps sorting, automatic punching, automatic detection etc. Pad tidy and in order, instead of manually put foils, solving problem speed and hygiene. It’s widely used in the pharmaceutical, chemical, food, health care products, chemicals and other industries. |

| Production line: | Cap liner inserting machine is normally applied with cap conveyor device. |

Technical specification:

| 1 | Machine name: |

Cap lining machine cap wadding machine cap liner inserting putting machine by quality factory |

| 2 | Model: | EV-SDJ |

| 3 | Lining heads: | 6(can be customized) |

| 4 | Sealing dia: | Customized |

| 5 | Speed: | 200-320ppm |

| 6 | Error Range: | ≤±1% |

| 7 | Single machine noise: | ≤50dB |

| 8 | Driven Type: | Electrical and Pneumatic |

| 9 | Compressed air pressure: | 0.4~0.6Mpa |

| 10 | Speed control: | Frequency conversion |

| 11 | Power: |

1.2KW,50-60HZ

220/380V/110V/415V (customized to different country) |

| 12 | Weight: | 400Kg |

| 13 | Dimension: | 2400*800*1500mm(Differ by lining heads) |

More information:

| 1 | Machine name: |

Cap lining machine cap wadding machine cap liner inserting putting machine by quality factory |

| 2 | Model: | EV-SDJ |

| 3 | Application: | Beverage, Chemical, Commodity, Food, Medical |

| 4 | Lining Type: | Aluminum foil, foam, plastic etc. |

| 5 | Machine material: | SUS 316 for medical; SUS304 for food or chemical |

| 6 | Certification: | CE, meet requirement of GMP |

| 7 | Place of origin: | Shanghai, China |

| 8 | MOQ: | 1 set |

| 9 | OEM Accepted: | Yes |

| 10 | After-sales Service: | Engineers available to service machinery overseas |

Shipping & Packaging:

Packaging & Shipping & Payment:

| 1 | Delivery time: | 30 days since receive deposit & bottles |

| 2 | Shipping: | By sea or by air |

| 3 | Packaging: | Standard exported wooden cases |

| 4 | Payment: | T/T, Western Union, Confirmed LC at sight; |

| 5 | Payment term: | 30% deposits, 70% balance before shipment |

Procedure from order to after-sale service:

| 1 | Inquiry-Professional quotation. |

| 2 | Confirm the technical layout, price, lead time, payment term etc. |

| 3 | Freedom sales send the proforma invoice. |

| 4 | Customer makes the payment as deposit and sends us bottles & caps. |

| 5 | We start manufacture machines. |

| 6 |

Middle Production-send photos to show the production line which you can see your machines in production.

Confirm the estimated delivery time again. |

| 7 | End Production machines photos and videos will be sent to you for approval. You can also arrange to our factory for Inspection. |

| 8 | Customers make payment for balance and we arrange to ship the machines. |

| 9 | Engineer is available for installation or after-sale service in factory overseas. |

| 10 | Feedback to Freedom about Quality, Service, Market Feedback & Suggestion. And we can do better. |

FAQ:

| 1 | Q: | Are you a factory? |

| A: |

We are a factory with more than 14 years’ experience in manufacturing various packing machines, factory occupied area of 3000 square meters, located in shanghai Jading district, about 30 minutes from Shanghai Hongqiao airport.

We have expert export team, familiar with whole foreign trade procedure, from shipping arrangement to custom clearance. |

|

| 2 | Q: | How about your machine quality? |

| A: | Every machine is applied with CE certificate, SGS certificate, highly meet requirement of GMP; Machine is fully made of SUS 304 for food packaging; SUS316 for pharmaceutical products packaging. Inspect certificate is available. | |

| 3 | Q: | What about the price? |

| A: | We promise the price we give out is lowest if same application, only to enlarge the market share. | |

| 4 | Q: | How about installation? |

| A: | Detail English instruction book is applied with every machine, and installation video is available. Engineer is available to your factory to teach and install. |