- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Customiaztion

-

Weight:

-

3000 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

220V/380V

-

Key Machines:

-

gummy depositor machine

-

Application:

-

gummy depositor machine

-

Function:

-

Injection molding

-

Material:

-

304 Stainless Steel

-

Power Source:

-

Electric/Gas/Oil

-

Capacity:

-

150-600kg/h

-

Model:

-

Customiaztion

-

Advantage:

-

Small Size

-

Shape:

-

Changeable units

-

Feature:

-

small outupt

-

Processing Types:

-

Cutomatization

Quick Details

-

Machinery Capacity:

-

80-2000kg/hour

-

Brand Name:

-

Junyu

-

Year:

-

Customiaztion

-

Dimension(L*W*H):

-

Customiaztion

-

Weight:

-

3000 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

220V/380V

-

Key Machines:

-

gummy depositor machine

-

Application:

-

gummy depositor machine

-

Function:

-

Injection molding

-

Material:

-

304 Stainless Steel

-

Power Source:

-

Electric/Gas/Oil

-

Capacity:

-

150-600kg/h

-

Model:

-

Customiaztion

-

Advantage:

-

Small Size

-

Shape:

-

Changeable units

-

Feature:

-

small outupt

-

Processing Types:

-

Cutomatization

Product Paramenters

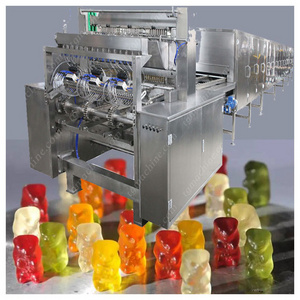

Jelly Candy / Gummy Candy Production line.

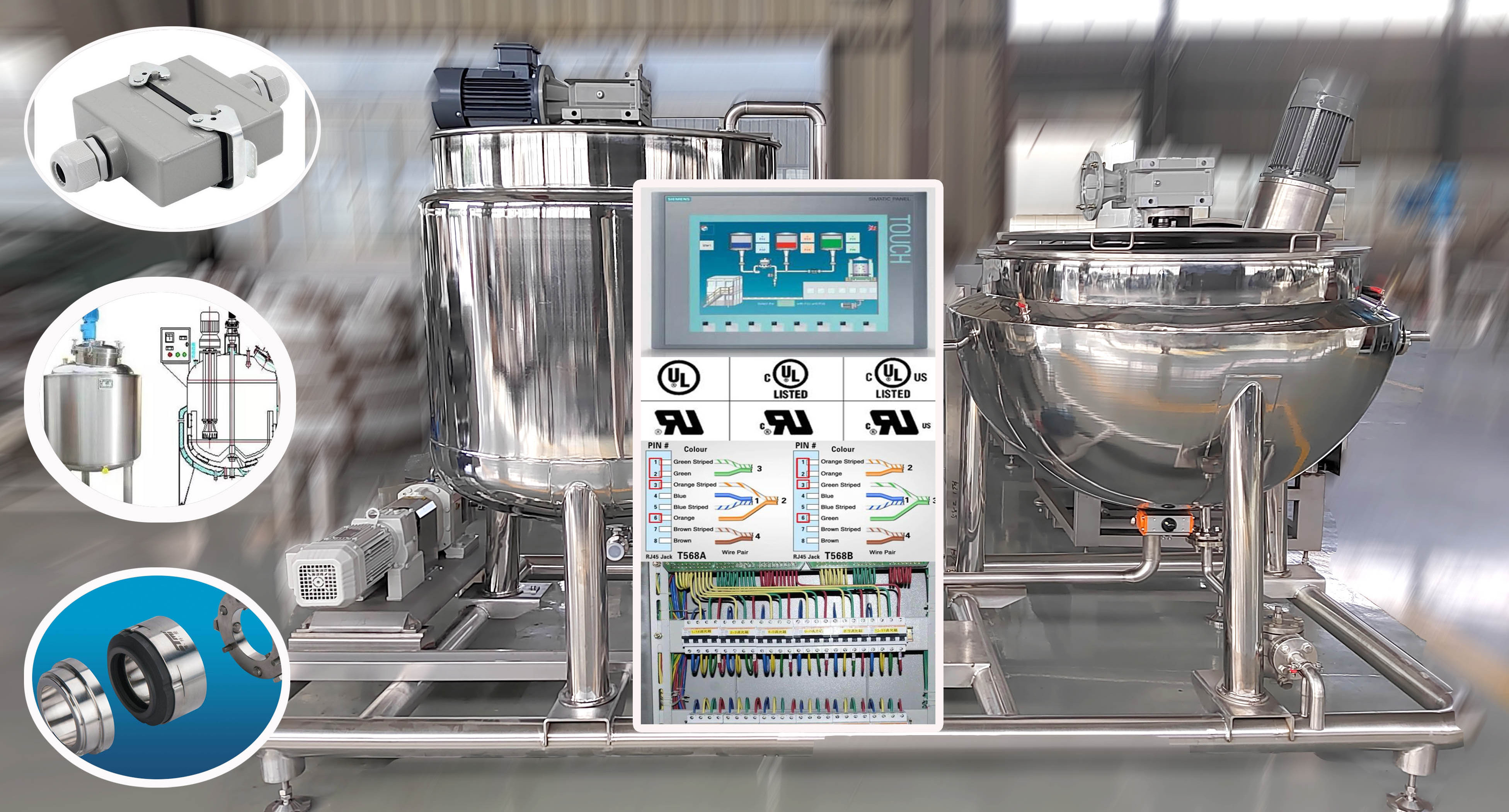

This machine line is an ideal equipment which can produce out good quality products with the saving of both the manpower and the space occupied. This depositing line consists of jacket dissolving cooker, gear pump, storage strainer, storage tank, discharging pump, color & flavor jigger, color & flavor mixer, cooling tunnel, electric control cabinet, etc.

|

Model

|

M80

|

M150

|

M300

|

M450

|

M600

|

|

Production capacity

|

80 kg/hour

|

150 kg/hour

|

300 kg/hour

|

450 kg/hour

|

600 kg/hour

|

|

Max candy weight

|

2-8 g/or more customized

|

2-8 g/or more customized

|

2-8 g/or more customized

|

2-8 g/or more customized

|

2-8 g/or more customized

|

|

Eletric Power

|

25 kw/380v

|

32 kw/380v

|

39 kw/380v

|

48 kw/380v

|

75 kw/380v

|

|

Total length

|

7m

|

17m

|

17m

|

18m

|

18m

|

|

Mould quantity

|

160pcs

|

240pcs

|

480pcs

|

720pcs

|

960pcs

|

Cooking system

It can be used to cook candy syrup, dissolve gelatin, and store the syrup to guarantee continuous working.

Pectin☑️

Gelatin☑️

Candy depositing unit

Depositing unit

1. Servo depositing

1. Servo depositing

2. Automatic oil spraying system,

3. Automatic demoulding.

3. Color and flavor-adding system .

3. Color and flavor-adding system .

All contact food parts by stainless steel

All the main motors or servo systems or celeriac components by Imported brands

3-6 months of local training and install

Food safety grade design assembly

3-year warranty

Annual or 2500 hours of devices care

Gummy & Jelly Varieties

machines can produce

With an ever-increasing demand for functional Gummies, we can help you create a high-output production line

suitable for all nutraceutical gummies including vitamin-based chewable candy.

Gelatin Gummies

We can help you perfect the classic gummy bear recipe and much more with our efficient manufacturing equipment. Traditional gelatin gummies have always been a favourite in the confectionery market

Pectin & Carrageenan Jellies

Pectin based are an ideal alternative to gelatin, Made from plant-based ingredients, those following a vegan diet can still enjoy the soft or chewy texture of all their favourite jellies. With vegan diets increasing in popularity.

Our depositing machines can produce others too

Servforming starch-free depositing systems can combine up to four com-ponents into a single candy in a range of different patterns.

Centrefillings, multi-colours, stripes, layers ,inclusions ,sugar-free and sugar options are all available to bring variety

and eye-catching appeal to the marketplace.

And some of our popular machines can produce Hard candy;Lollipop;Toffee&Caramels.

Q&A

What is the difference between pectin,carrageenan and gelatin?

What are the equipment requirements for the different gum bases?

What are the temperature requirements for boiling/Kitchen gum base?

What are the benefits/differences of your boiling/kitchen equipment?

What are the benefits of the soft candy cooker?

What is the material of the equipment?

What is the advantage of servo pouring candy line?

Can I pack the soft candy directly after it is made?

What are the requirements of drying work shop size time and temperature?

What is the purpose and difference between thesugar machine and the oiling machine?

What is the temperature range of the cooling tunnel?

What is the waterproof level of the motor?

What certifications do you have?

What is the wiring standard?

What is the brand of the electrical appliances?(Contact us for others)

What is the after-sales service? Can you install-and debug at home?

What is the material of the conveyor belt?

Customer Case

Why Choose Us

Hot Searches