- Product Details

- {{item.text}}

Quick Details

-

Machine body:

-

strong Welded steel structure

-

Drive motor:

-

Yaskawo Sevo optional

-

Spindle power:

-

9.0kw itally HSD optional

-

Transmission:

-

X, Y rack driving, Z screw ball driving

-

control system:

-

NCSTUDIO/TAIWAN SYSTEC optional

-

TABLE:

-

loading and unloading tables

-

Certification:

-

CE ISO SGS BV

Quick Details

-

Place of Origin:

-

Shandong, China

-

After-sales Service Provided:

-

Online support, Video technical support, Engineers available to service machiner

-

Applicable materails:

-

wood, mdf, plywood, acrylic, marble, metal and etc.

-

Machine body:

-

strong Welded steel structure

-

Drive motor:

-

Yaskawo Sevo optional

-

Spindle power:

-

9.0kw itally HSD optional

-

Transmission:

-

X, Y rack driving, Z screw ball driving

-

control system:

-

NCSTUDIO/TAIWAN SYSTEC optional

-

TABLE:

-

loading and unloading tables

-

Certification:

-

CE ISO SGS BV

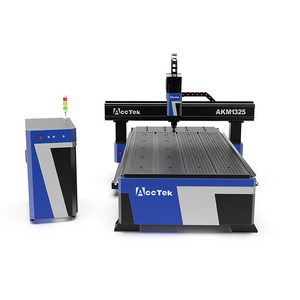

cnc wood router/1325 furniture engraving cutting machine/wood carving cnc router

Product Description

Advantage of ACUT woodworking cnc router:

1. 1325 wood cnc router Working area: 1300*2500*200mm( Z can be higher if necessary)

2. Italy HSD 9.0kw air cooling spindle

3.Models of Wood CNC router:1325, 1530, 2030, 2040(size can be made accroding to customers' request)

4. Drum style ATC wood CNC router

5. High quality, competive price CNC Router

6. Provide OEM service

7. with loading and unloading tables/life table

8.with boring head

9.with Tool Magazine

10. TAIWAN SYSTEC SYSTEM

11.with automatic oil sytem

12.with vacuum t-slot table

13.with Taiwan EUROVAC Oilless Vacuum Pump,and dust

14.Japanese Yaskawa Servo motor and driver

15.Taiwan PMI square rail

Application:

suitable for solid wood furniture, solid wood door, computer desk, mahjong, board type furniture, office furniture

Performance characteristics :

1. fission key board control,ensure users operate easily.

2. Advanced Taiwan control system,Intelligent processing cross-border protection function,can prevent mechanical impact caused by the improper design documents. and control the processing speed,improve the processing efficiency .

3. Dust collection suck the wood chips,keep the working table clean. Vacuum table can absorb the material, save the plate loading and unloading time.

4. Advanced file preprocessing function,help users to correct errors in a timely. And be Be compatible with several CAD/CAM designing software

5. Recover caving point after break of disconnecting power.Automatic error correction function guarantee the engraving precision for long time processing.

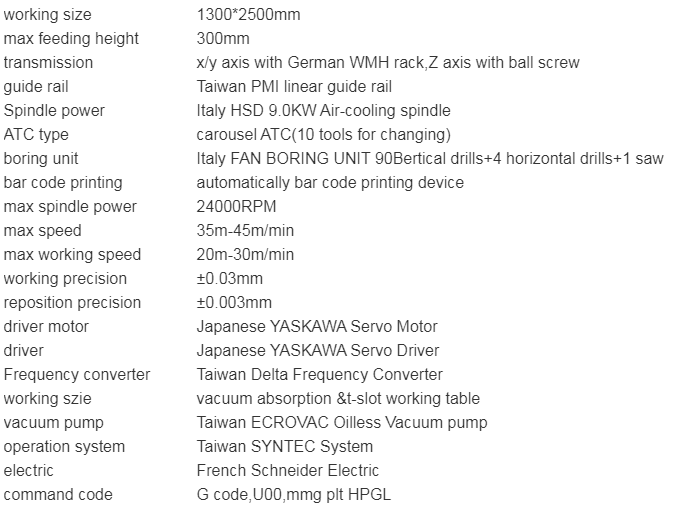

Parameters:

Main parts :

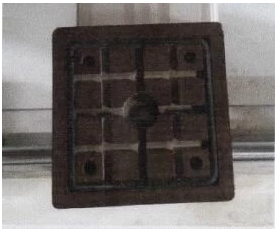

Vacuum absorption blocks

Taiwan Syntec Control System

Bar code printing ( from Japan )

This part is put at the loading area, bar code printing device will be installed at the single arm structure, it is convenient for you to load material

Japanese YASKAWA Servo system ( servo motor and driver)

Boring Head Unit

Samples :