2. Automotive industry:

high-performance engine components, wheel bearings, brake systems, etc.

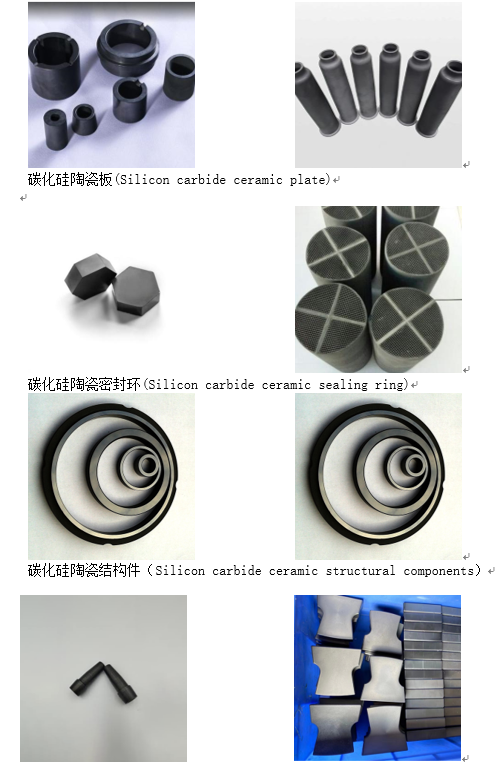

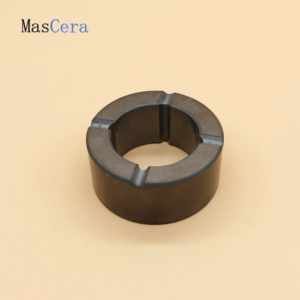

3. High temperature and wear-resistant components:

high-temperature bearings, bulletproof plates, nozzles, high-temperature

corrosion-resistant components, as well as electronic equipment components in the high temperature and high frequency range.

corrosion-resistant components, as well as electronic equipment components in the high temperature and high frequency range.