Product overview

In the

industrial and automotive fields

, a certain pressure value is usually set for the equipment when the pressure reaches this value, the system will send an electronic signal to start the mechanical equipment which triggers a warning (such as a leak of equipment, an alarm, etc.). This is the

plunger type pressure switch

. The max pressure can not be exceeded to

600 bar

.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

WTsensor

-

Model Number:

-

PCS101

-

Max. Current:

-

4A

-

Max. Working Pressure:

-

6500PSI(450Bar)

-

Medium:

-

Liquid Air Water Gas

-

Certification:

-

CE ISO9001 RoHS

-

Pressure Range:

-

0-450 Bar

-

Electrical:

-

4A,125V/250VAC or 4A,12/42VDC

-

Protection rating:

-

IP65,IP67

-

Material:

-

Stainless Steel

-

Repeatability:

-

± 2% of full set point range at 21°C Ambient Temperature

-

Switch type:

-

Snap Action

-

Mechanical life:

-

100,000 cycles

-

Maximum Overload pressure:

-

6500 PSI (450 Bar)

Quick Details

-

Whether the smart:

-

NO

-

Max. Voltage:

-

42VDC

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

WTsensor

-

Model Number:

-

PCS101

-

Max. Current:

-

4A

-

Max. Working Pressure:

-

6500PSI(450Bar)

-

Medium:

-

Liquid Air Water Gas

-

Certification:

-

CE ISO9001 RoHS

-

Pressure Range:

-

0-450 Bar

-

Electrical:

-

4A,125V/250VAC or 4A,12/42VDC

-

Protection rating:

-

IP65,IP67

-

Material:

-

Stainless Steel

-

Repeatability:

-

± 2% of full set point range at 21°C Ambient Temperature

-

Switch type:

-

Snap Action

-

Mechanical life:

-

100,000 cycles

-

Maximum Overload pressure:

-

6500 PSI (450 Bar)

Product Description

WTsensor

PCS101

Automotive Industrial Adjustable Low Pressure Switches

Features

■ 1 million mechanical life and high reliability

■Short action time and high sensitivity

■ High pressure resistance and high safety

■With metal shell design, the switch is more resistant to vibration and external impact

■Pressure value can be adjusted

■More shell types/pressure range/thread types/diaphragm types can be selected, which is suitable for more use occasions and has high adaptability

Applications

■Construction machinery,such as excavators

■Forklift truck (oil burning type with hydraulic system)

■Hydraulic system,such as hydraulic lubrication pump and hydraulic pump station

Specification

|

Performance Parameters

|

|

|

|

|

|||

|

Model

|

Adjustment Range

|

|

Avg. Differential

|

|

|||

|

|

PSIBar

|

|

PSIBar

|

|

|||

|

1

|

450-1450

|

30-100

|

72.5 - 290

|

5 -20

|

|||

|

2

|

725-2175

|

50-150

|

145-435

|

10-30

|

|||

|

3

|

1450-2900

|

100-200

|

218 - 580

|

15 -40

|

|||

|

Electrical

|

Standard:4A,125V/250VAC

4A,12/42VDC Gold contacts may be required for less than12 VDC and 20 milliamps |

|

|

|

|||

|

Wetted material

|

Diaphragm: Buna-N (standard)

(optional EPDM,FKM, VITON® HNBR) Housing: Zinc-plated steel, 304 Stainlesssteel,316L Stainlesssteel |

|

|

|

|||

|

Protection

|

Exposed Terminals -IP00

DIN 43650A-IP65 Flying Leads, M12, Deutsch Integral - IP67 |

|

|

|

|||

|

Repeatability

|

± 2% of full set point range at 21°C

Ambient Temperature |

|

|

|

|||

|

Switch type

|

Snap Action

|

|

|

|

|||

|

Mechanical life

|

100,000 cycles

|

|

|

|

|||

|

Temperature range

|

BUNA-N: -30℃~110℃

EPDM: -40-130℃ FKM: -10-120℃ VITON®: -40-130℃ HNBR: -40℃~130℃ |

|

|

|

|||

|

Maximum Overload pressure

|

6500PSI(450Bar)

|

|

|

|

|||

|

Weight

|

0.14 kg

|

|

|

|

|||

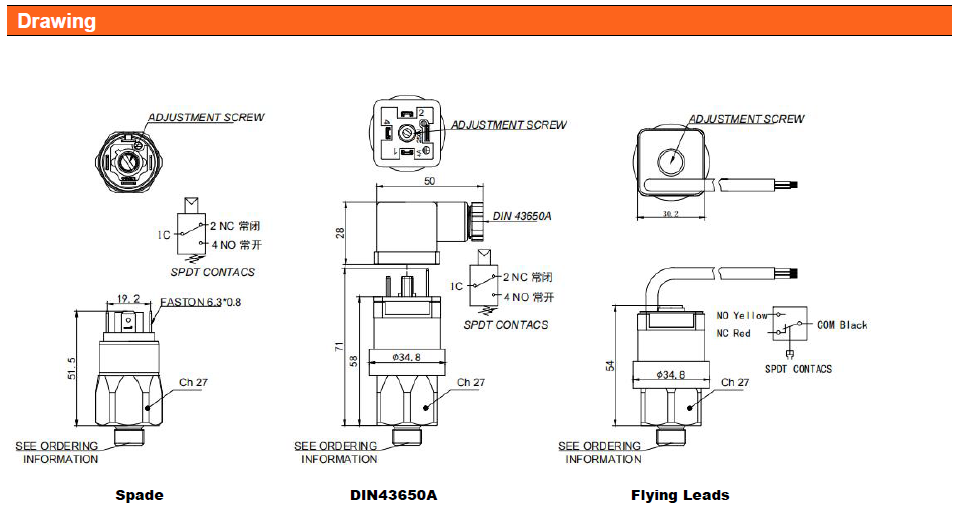

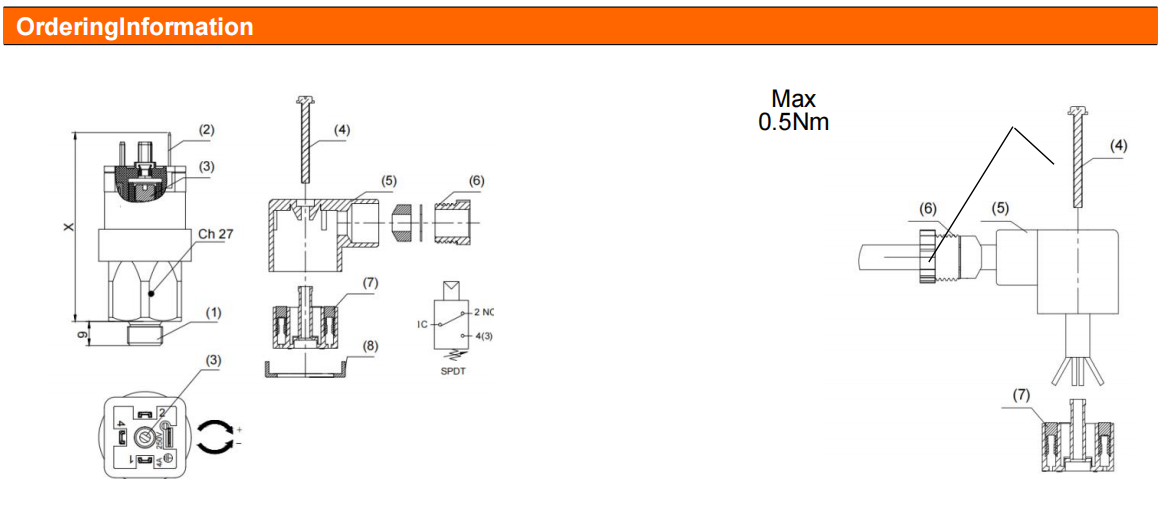

(1) Hydraulic/pneumatic connection

(2) Electrical connection

(3) Trip setting adjusting screw

(4) Mounting screw

(5) Plug housing

(6) Pg screw coupling with seal and backup ring

(7) Terminal board

(8) Profiled seal

Electrical:

1.Remove the fastening screws (4) from the head end Terminal board(7)

2. Connect the cable (max . lead cross-section 1,5 mm2) to the screw terminals provided

3.Rein stall the terminal board (7) in the plug housing (5) . Install the fastening screw (4) . Install the connector on the pressure switch and tighten the fastening screw (4) .

|

Material Compatibility

|

|

|

|

|||

|

Media

|

Buna

|

EPDM

|

Viton

|

|||

|

Acetic Acid

|

|

﹡

|

|

|||

|

Acetone

|

|

﹡

|

|

|||

|

Acetylene

|

﹡

|

|

|

|||

|

Air

|

﹡

|

|

|

|||

|

Alcohols

|

﹡

|

|

|

|||

|

Alkalies (Weak)

|

﹡

|

|

|

|||

|

Alkalies (Strong)

|

|

﹡

|

|

|||

|

Ammonia(Anhydrous)

|

﹡

|

|

|

|||

|

Ammonia(Hydroxide)

|

|

﹡

|

|

|||

|

Asphalt

|

|

|

﹡

|

|||

|

Automotive Oils

|

﹡

|

|

|

|||

|

Beer

|

﹡

|

|

|

|||

|

Benzene

|

|

|

﹡

|

|||

|

Boric Acid

|

﹡

|

|

|

|||

|

Brake Fluid

|

|

﹡

|

|

|||

|

Bunker Oil

|

﹡

|

|

|

|||

|

Butane

|

﹡

|

|

|

|||

|

Butyl Cellosolve

|

|

﹡

|

|

|||

|

Carbon Dioxide

|

﹡

|

|

|

|||

|

Carbon Monoxide

|

﹡

|

|

|

|||

|

Cellube

|

|

﹡

|

|

|||

|

Chiorobenzene

|

|

|

﹡

|

|||

|

Citric Acid

|

﹡

|

|

|

|||

|

Coke Oven Gas

|

|

|

﹡

|

|||

|

Coolant

|

﹡

|

|

|

|||

|

Diesel Fuels

|

﹡

|

|

|

|||

|

Di-Ester Lube(MIL-L-7808)

|

|

|

﹡

|

|||

|

Dowtherm A&E

|

|

﹡

|

|

|||

|

Ethanol

|

﹡

|

|

|

|||

|

Ether

|

|

﹡

|

|

|||

|

Ethylene

|

﹡

|

|

|

|||

|

Ethylene Glycol

|

﹡

|

|

|

|||

|

Freon

11,12,112,114 |

﹡

|

|

|

|||

|

Freon 22

|

|

﹡

|

|

|||

|

Fyrquel

|

|

﹡

|

|

|||

|

Fuel Oil

|

﹡

|

|

|

|||

|

Gasoling

|

﹡

|

|

|

|||

|

Glycerin

|

﹡

|

|

|

|||

|

Helium

|

﹡

|

|

|

|||

|

Hexane

|

﹡

|

|

|

|||

|

|

|

|

|

|||

|

Media

|

Buna

|

EPDM

|

Viton

|

|||

|

Hydraulic Oil(PETBase)

|

﹡

|

|

|

|||

|

Hydrocarbons

|

﹡

|

|

|

|||

|

Hydrogen

|

﹡

|

|

|

|||

|

Hydrogen Sulphide

|

|

﹡

|

|

|||

|

Isopropanol

|

|

﹡

|

|

|||

|

JP-3-6

|

﹡

|

|

|

|||

|

Kerosene

|

﹡

|

|

|

|||

|

LPG

|

﹡

|

|

|

|||

|

Lube Oil(PET Base)

|

﹡

|

|

|

|||

|

Methanol

|

﹡

|

|

|

|||

|

MEK

|

|

﹡

|

|

|||

|

Mineral Oil

|

﹡

|

|

|

|||

|

Motor Oils

|

﹡

|

|

|

|||

|

Naptha

|

|

﹡

|

|

|||

|

Natural Gas

|

﹡

|

|

|

|||

|

Nitric Acid

|

|

﹡

|

|

|||

|

Nitrogen

|

﹡

|

|

|

|||

|

Cleum Spirits

|

|

|

﹡

|

|||

|

Oxygen

|

﹡

|

|

|

|||

|

Ozone

|

|

﹡

|

|

|||

|

Crude Oil

|

﹡

|

|

|

|||

|

Phosphoric Acid

|

|

|

﹡

|

|||

|

Propane

|

﹡

|

|

|

|||

|

Propanol

|

﹡

|

|

|

|||

|

Pydraul

|

|

﹡

|

|

|||

|

Shell Iris 902

|

﹡

|

|

|

|||

|

Silicone Greases

|

﹡

|

|

|

|||

|

Silicone Oils

|

﹡

|

|

|

|||

|

Skydrol 500 & 7000

|

|

﹡

|

|

|||

|

Soap Solutions

|

﹡

|

|

|

|||

|

Steam Below 320°F

|

|

﹡

|

|

|||

|

Stoddard Solvent

|

﹡

|

|

|

|||

|

Sulfuric Acid

|

|

|

﹡

|

|||

|

Tolulene

|

|

|

﹡

|

|||

|

Transmission Fluid

|

﹡

|

|

|

|||

|

Trisodium Phosphate

|

﹡

|

|

|

|||

|

Turpentine

|

﹡

|

﹡

|

|

|||

|

Water to 220°F (104°C)

|

﹡

|

|

|

|||

|

Water to 302°F (150°C)

|

|

﹡

|

|

|||

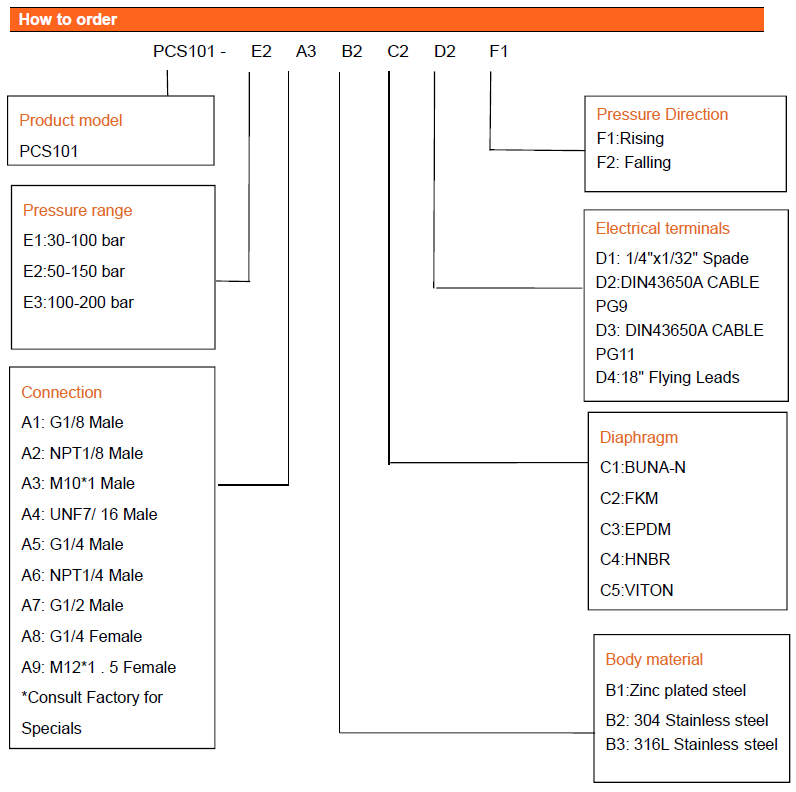

Example:

PCS101-E2A3B2C2D2F1

The product model is PCS101, E2: pressure range 50-150 bar, A3: connection M10*1 Male, B2: 304 stainless steel for body material, C2: FKM diaphragm, D2: DIN43650A CABLE PG9, F1: pressure direction rising.

The product model is PCS101, E2: pressure range 50-150 bar, A3: connection M10*1 Male, B2: 304 stainless steel for body material, C2: FKM diaphragm, D2: DIN43650A CABLE PG9, F1: pressure direction rising.

FAQ

1. Are you manufacturer or trading company?

We are manufacturer which focuses on pressure industry for 33 years.. There are total about 201-300 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Pressure Sensor/Pressure Transmitter/Level Sensor/pressure switch

4. why should you buy from us not from other suppliers?

Nanjing Wotian Technology Co., Ltd. is one of the largest manufacturer of diffused silicon pressure sensors in China, with more than 33 years' experiences in research, development and production of pressure sensors, level sensors and temperature sensors.

5. what services can we provide?

Accepted Delivery Terms: FCA;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T;

Language Spoken:English,Chinese

6.What international certificates do you have?

ISO9001, CE, RoHS Certificated.

7.What is the lead time of your product?

Stocks are available for some products. The typical lead time is 8~14 working days for product without customization. Note: lead time may vary base on different products. Please contact us for detailed lead time.

8. What is the warranty of your products?

Our warranty time is 18 months after shipment.

9. Do you provide customized products?

Yes, we can laser mark your logo, model and product information according to your requirement. We provide OEM and ODM service.

Hot Searches