2.Main Raw Material

1) Base Material: BOPP tape film

2

)

Gule: water based pressure sensitive adhesive

3.Main Coating Way:Comma knife style coating

- Product Details

- {{item.text}}

Quick Details

-

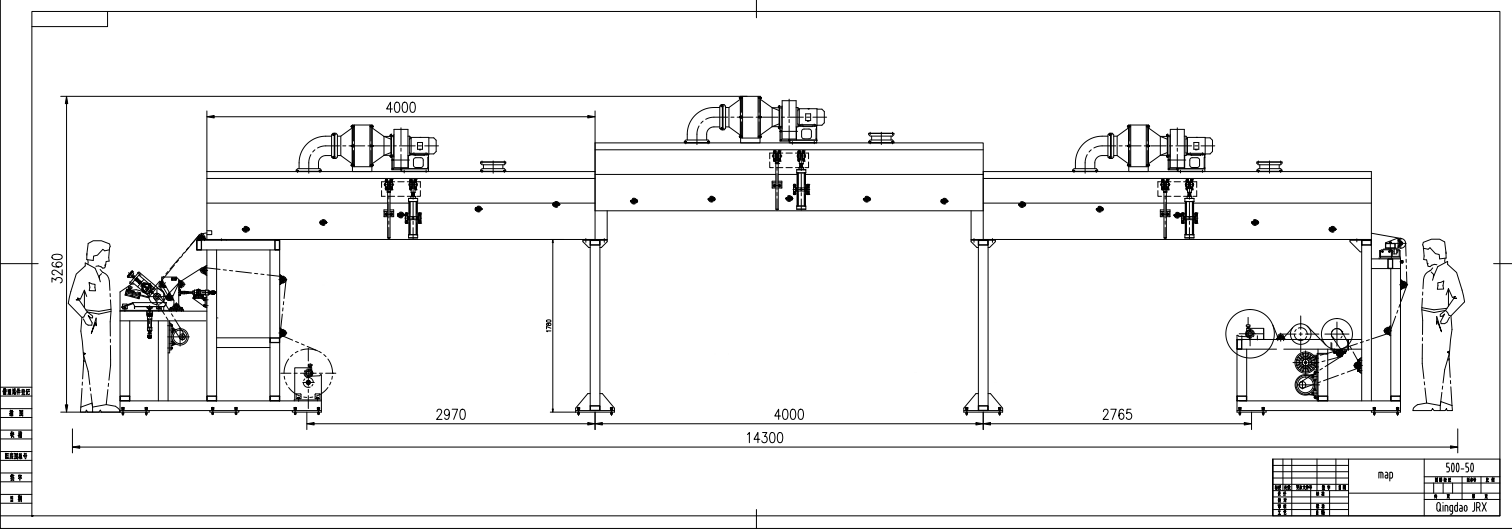

Dimension(L*W*H):

-

17*4*4m

-

Name:

-

Adhesive Tape Applying Machine BOPP Gluing Machine

-

Coating Speed:

-

10-90m/Minute Can Be Customized

-

Coating Width:

-

500-2500mm Can Be Customized

-

Video Outgoing-Inspection:

-

Provided

-

Dry Way:

-

Hot Air

-

Unwinding Diameter:

-

500-1500mm Can Be Customized

-

Winding Diameter:

-

500-1500mm Can Be Customized

-

Model:

-

JRX

Quick Details

-

Voltage:

-

220v/380v

-

Place of Origin:

-

China

-

Weight:

-

65 KG

-

Dimension(L*W*H):

-

17*4*4m

-

Name:

-

Adhesive Tape Applying Machine BOPP Gluing Machine

-

Coating Speed:

-

10-90m/Minute Can Be Customized

-

Coating Width:

-

500-2500mm Can Be Customized

-

Video Outgoing-Inspection:

-

Provided

-

Dry Way:

-

Hot Air

-

Unwinding Diameter:

-

500-1500mm Can Be Customized

-

Winding Diameter:

-

500-1500mm Can Be Customized

-

Model:

-

JRX

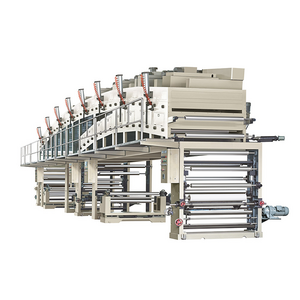

Product Overview

Tape coating machine

1.This machine is special for producing the BOPP adhesive tape,also suitable for continuous coating of roll materials with excellent printing performance such as PET, PVC, PE, NY and paper.

Specification and Capability

|

Effective Coating Width

|

1300mm

|

|

Roller surface width

|

1450mm

|

|

Mechanical Speed

|

10m/min~50m/min

|

|

Max Running Speed

|

10 -40m/min (dry glue 25g/m2 , solid content ≥55%)

|

|

Max Unwinding Diameter

|

1400mm

|

|

Max Rewinding Diamter

|

1450mm

|

|

Heating and Drying Way

|

electric type

|

|

Temperature Control

|

Max 120℃

|

|

The tidiness of the coiling edge

|

surface tidiness error ≤3mm

|

|

Average Degree of Coating

|

Dry Glue≤0.003mm

|

|

Electrical Total Power

|

90KW

|

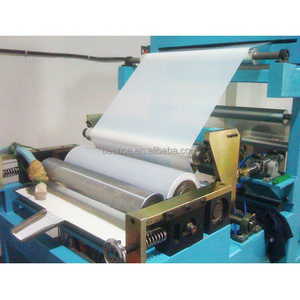

There are two coating methods of tape coater: one is to apply photosensitive emulsion on the screen through multiple wet pressing operations; Or add the drying process after each coating. A machine for quantitatively coating liquid (or melt) polymer materials such as adhesives or coatings on the surface of materials.It is suitable for the production of soft substrates such as pvc/pe film

Simply put, glue is applied to the film. Specifically, it includes gluing, drying, winding and tension control.The film can be PVC, PE, pet... Or some paper, for example, coated with hot melt adhesive on release paper

|

Coating Style

|

comma knife type Coating

|

|

Effective Coating Width

|

1300mm

|

|

Comma Scraper

|

the surface is the fine hard chrom, the super fine working accuracy 0.005mm

|

|

Glue feeding Roller

|

the surface is the fine hard chrome, accuracy 0.005mm

|

|

Rubber Roller

|

material: silicone rubber, accuracy 0.01mm, the bearing in the two ends is imported, cylinder control

|

|

Space Adjustment

|

oblique steel solid to control the glue coating quantity

|

|

Pre-scraper Board

|

the entrance is tetrafluoroethylene

|

|

Material Basin

|

Stainless steel, manual for lifting

|

|

Machine Shelf

|

25mm plate Welding

|

|

Driving Structure

|

Cycloid Speed Reducer Motor

|

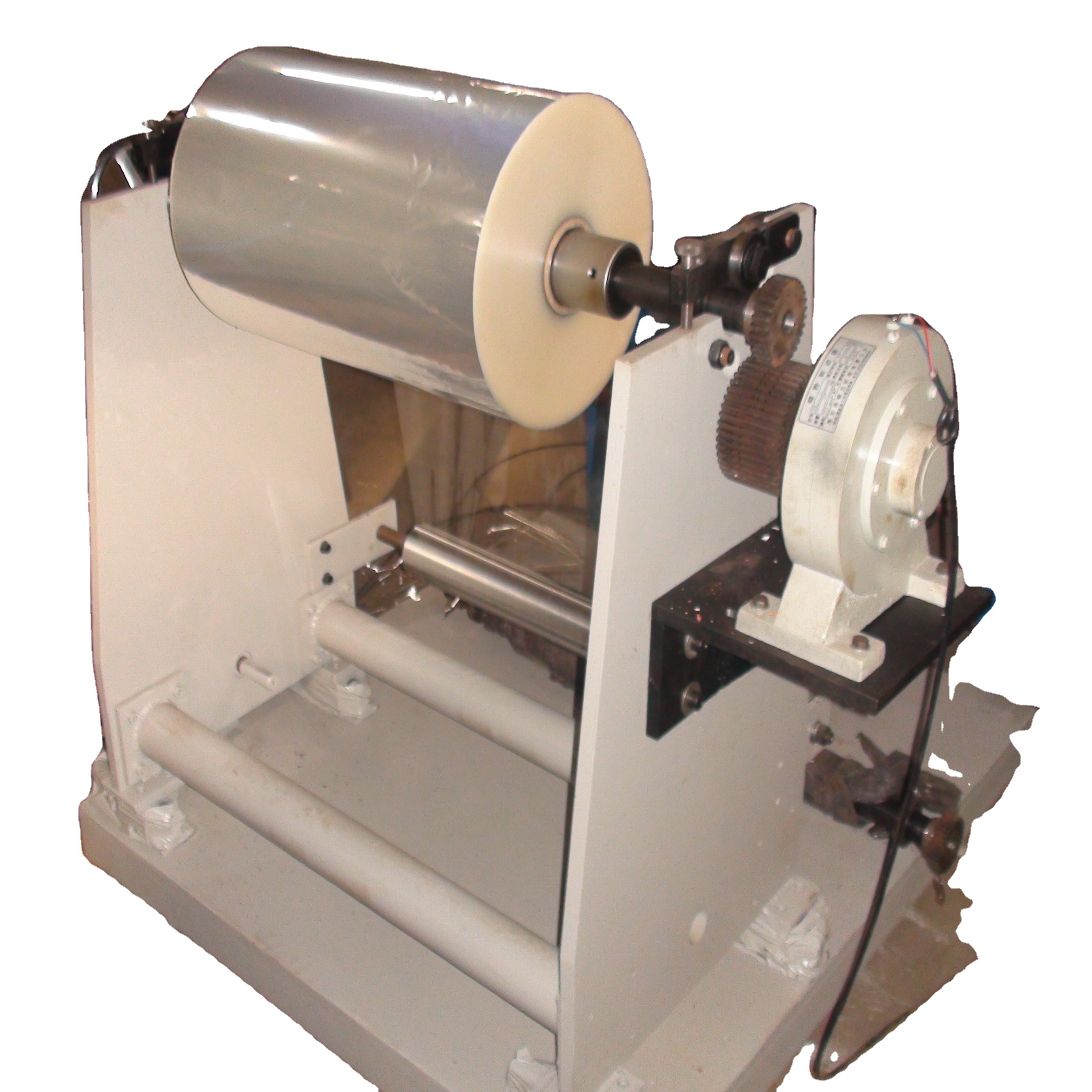

Device Configuration

Uniaxial unwinder

2.Effective Unwinding Width:1300mm

3.Effective Unwinding Diameter:1400mm

4

.Unwinding Shaft:Pneumatic Shaft 2 pieces

5.Unwinding Tension Control:Magnetic Power Brake, Tension Open Loop automatic control 1 set

6.Alignment :Auto rectification(EPC)

Coating Head

Oven box

Uniaxial rewinder

Electric Control System

Slitting Machine

Hot Searches