- Product Details

- {{item.text}}

Quick Details

-

Spindle Bore(mm):

-

42

-

Width of bed (mm):

-

240 mm

-

Spindle Motor Power(kW):

-

3

-

Travel (X Axis)(mm):

-

160 mm

-

Travel (Z Axis)(mm):

-

240 mm

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

1550*920*1450

-

Brand Name:

-

Lu Young

-

Model Number:

-

Ck0640

-

Voltage:

-

3 Phase 380V 50HZ

-

Weight (KG):

-

1000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Automatic Grade:

-

Automatic

-

CNC or Not:

-

CNC

-

Machine Type:

-

CK0640 mini torno mechanic cnc lathe with auto bar feeding

-

Max.swing over bed:

-

300mm

-

Spindle bore:

-

42mm

-

Spindle speed:

-

150-2500rpm

-

Tool holder:

-

Gang type tool holder

-

Chuck:

-

Pneumatic Collet

-

Control system:

-

SIEMENS GSK FANUC (optional)

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

-

Certification:

-

CE ISO

Quick Details

-

Type:

-

Horizontal

-

Max. Length of Workpiece (mm):

-

240

-

Max. Spindle Speed (r.p.m):

-

2500 r.p.m

-

Spindle Bore(mm):

-

42

-

Width of bed (mm):

-

240 mm

-

Spindle Motor Power(kW):

-

3

-

Travel (X Axis)(mm):

-

160 mm

-

Travel (Z Axis)(mm):

-

240 mm

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

1550*920*1450

-

Brand Name:

-

Lu Young

-

Model Number:

-

Ck0640

-

Voltage:

-

3 Phase 380V 50HZ

-

Weight (KG):

-

1000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Automatic Grade:

-

Automatic

-

CNC or Not:

-

CNC

-

Machine Type:

-

CK0640 mini torno mechanic cnc lathe with auto bar feeding

-

Max.swing over bed:

-

300mm

-

Spindle bore:

-

42mm

-

Spindle speed:

-

150-2500rpm

-

Tool holder:

-

Gang type tool holder

-

Chuck:

-

Pneumatic Collet

-

Control system:

-

SIEMENS GSK FANUC (optional)

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

-

Certification:

-

CE ISO

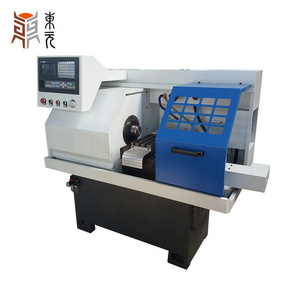

CK0640 mini torno mechanic cnc lathe with auto bar feeding

CK0640 mini torno mechanic cnc lathe with auto bar feeding using the GSK controller system to realize the Two - axis Control .The use of FANUC, Siemens, KND and other systems; with less noise, high precision, excellent performance characteristics, the CNC machine tools using mechanical and electrical integration design. Beautiful appearance, reasonable structure, wide range of uses, easy to operate. The machine can be automatically controlled, can automatically process a variety of parts of the first round, end, slot, any cone, spherical, and a variety of British and English cylindrical, tapered thread

specification of CK0640 mini torno mechanic cnc lathe with auto bar feeding

| CK0640 mini torno mechanic cnc lathe with auto bar feeding | |||

| Item | Parameter | Unit | CK0640 CNC LATHE |

| Capacity | Max.swing over bed | mm | Φ300 |

| Max.swing over cross slide | mm | Φ130 | |

| Max.workpiece length | mm | 240 | |

| Spindle | spindle speed | rpm | 50-2500 |

|

Fast feeding

speed |

X-axis Fast feeding

speed |

m/min | 1-2000 |

|

Z--axis Fast feeding

speed |

m/min | 1-1800 | |

| Axis stroke | X-axis travel stroke(mm) | mm | 200 |

| Z--axis travel stroke(mm) | mm | / | |

| Power | Main motor power | KW | 3 |

| Clamping | Type | / | Pnematic collet |

|

Thread machining

scope |

Metric system(mm) | mm | 0.25~12 |

| British system | 28~3 1/2 | ||

| Tailstock | Tailstock sleeve dia. | mm | / |

| Tailstock sleeve travel | mm | / | |

| Tailstock sleeve taper | / | ||

| Dimension | length× width × high | mm | 1550×920×1450 |

| Weight | Net weight | KG | 850 |

| Standard configuration | Option configuration | ||

| GSK928TD-L | Siemens, Fanuc cnc controller | ||

| Pneumatic spring collet(2pcs free) | Pneumatic chuck | ||

| Gang type tool carrier | 4 station electrice tool holder | ||

| Auto lubrication system | Auto feeder system | ||

| Lighting system | Hydraulic chuck | ||

| cooling system | tailstock | ||

| 380V 3 phase | if your local have special request pls let us know | ||

Hot selling flat bed high precision CNC lathe machine for metal

|

CK0640 mini CNC lathe machine CK6432 small CNC lathe machine |

|

CK6130 small CNC lathe machine CK6132 small CNC lathe machine |

|

|

|

CK6150heavy duty CNC lathe machine CK6180 heavy duty CNC lathe machine |

Feature of CK0640 mini torno mechanic cnc lathe with auto bar feeding

1.

Improve efficiency

. The speed of the clamping of the workpiece through the spring collet is one third more than the manual chuck, even much faster than the hydraulic chuck. A skilled worker can operate 2-3 machines at the same time.

2.

Configured the automatic feeding device

, can ensure that the workpiece does not bend deformation in the machine under the rapid operation.Applicable to batch processing of the workpiece that diameter from 5mm to 42mm, length within 3m.

3.

More accurate and efficiently

,the bed rails work more efficiently than engine lathe , the ball screw is more accurate,too.

4.

Use for long time

,ultra-audio quenching, The lathe bed and guide through the ultra-audio quenching, it could work more than 2 or 3 years of time than before.

5.

Good protection

,totally closed protection, better protection for rails, ball screws and bearings.

6.

Good lubrication

, it use of centralized lubricating oil, effective lubrication of each parts, increase the life of the lathe for at least 3 years.

Why choose our CK0640 mini torno mechanic cnc lathe with auto bar feeding ?

1.

Strong strength

,The company has 20 years of production experience, rich product range to meet the needs of different customers.

2.

Quality product

,Workshop workers skilled and rigorous testing of product quality, strict control of each production process.

3.

Direct factory price

,provide competitive factory price and save your costs.

4.

7×24 hours after-sale service

,Any questions, please contact us directly at any time

5.

Strong packing

,will protect the goods from any possible damage during transit.

6.

TRADE ASSURANCE

,protect your orders from payment to delivery.