- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Jin Tong

-

Model Number:

-

Disc Magnet 23032402

-

Size:

-

All sizes is ok

-

Magnetism Direction:

-

Customized , Axial, Diameter, and so on

-

Coating:

-

Ni, Zn, NiCuNi, gold,epoxy, etc

-

Sample:

-

Avaliable

-

Material:

-

Sintered Neodymium-Iron-Boron

-

Certification:

-

ISo9001,MSDS, ROHS,etc

-

Testing:

-

Guass Meter, Fluxmeter,SST, etc

-

Working Temperature:

-

80℃~230℃

-

Name:

-

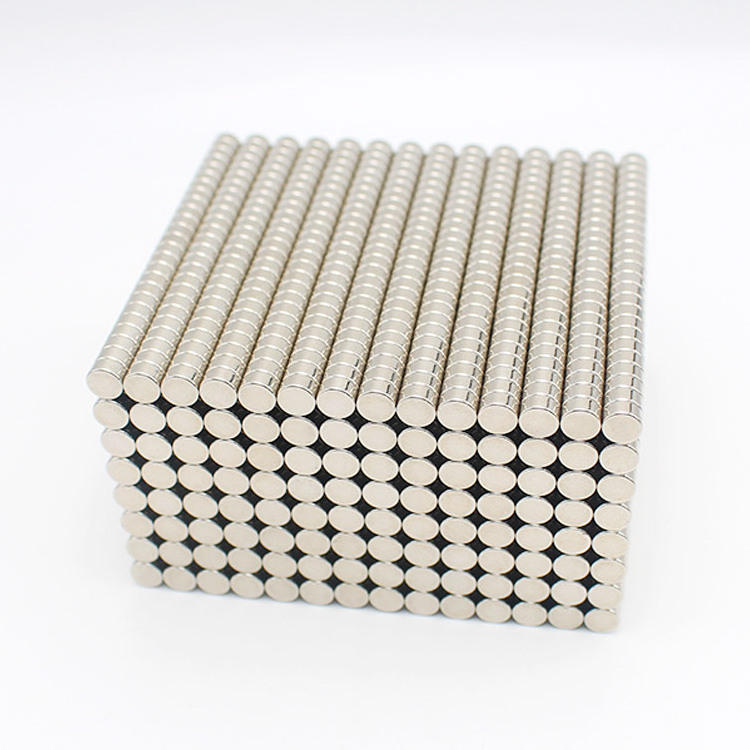

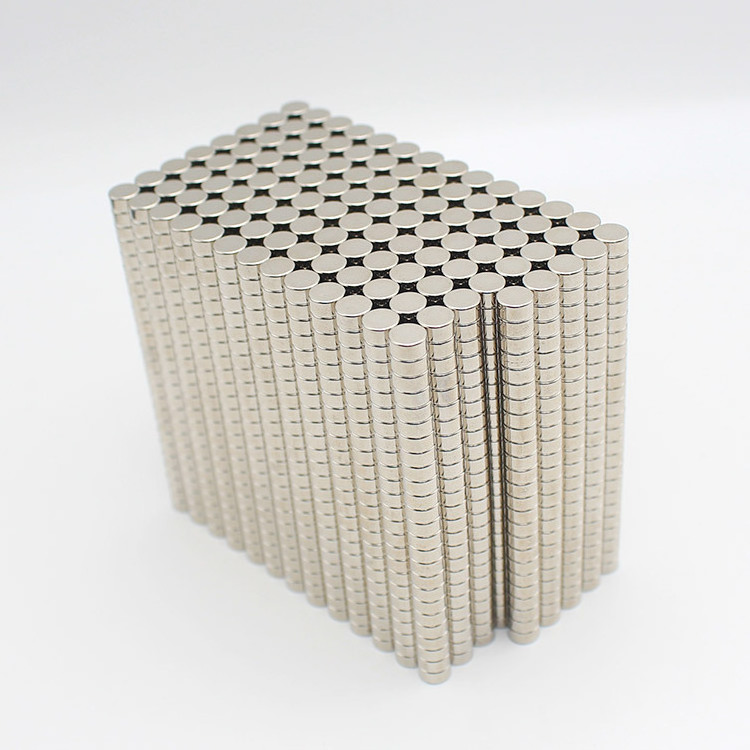

6x3mm magnet

Quick Details

-

Tolerance:

-

±5%

-

Grade:

-

N35-N52(M,H,SH,UH,EH,AH)

-

Place of Origin:

-

Shanxi, China

-

Brand Name:

-

Jin Tong

-

Model Number:

-

Disc Magnet 23032402

-

Size:

-

All sizes is ok

-

Magnetism Direction:

-

Customized , Axial, Diameter, and so on

-

Coating:

-

Ni, Zn, NiCuNi, gold,epoxy, etc

-

Sample:

-

Avaliable

-

Material:

-

Sintered Neodymium-Iron-Boron

-

Certification:

-

ISo9001,MSDS, ROHS,etc

-

Testing:

-

Guass Meter, Fluxmeter,SST, etc

-

Working Temperature:

-

80℃~230℃

-

Name:

-

6x3mm magnet

Welcome to inquiry!

| Product Description |

| Product Name | High Performance Cheap Strong N52 Small Magnet 3Mm Neodymium 6X3mm Magnet | |

| Material | Neodymium-Iron-Boron N35-N52 | |

| Size | Various kinds or according to customers' request | |

| Shape | Disc, Block, Ring, Countersunk, Segment, Trapezoid, Irregular shapes are available, Or Customized Shapes | |

| Working Temperature | Grade | Max. Operating Temperature |

| N35-N52 | 80 °C (176°F) | |

| 33M- 48M | 100°C (212°F) | |

| 33H-48H | 120°C (248°F) | |

| 30SH-45SH | 150°C (302°F) | |

| 30UH-40UH | 180°C (356°F) | |

| 28EH-38EH | 200°C (392°F) | |

| 28AH-35AH | 220°C (428°F) | |

| Certification | ISO9001, MSDS, SGS, ROHS,REACH,etc | |

| Applications |

1. Electronic areas: speakers, headphones, acoustics, sensors and so on. 2. Motor areas: generators, servo motors, micro-motors, vibration motors, elevator motor and so on. 3. Clean Tech Energy: Water flow enhancement, wind turbines. 4. Health care: MRI, medical treatment equipment. 5. Other industries: electric doors and windows, electric vehicle, electric bicycles, computer, phone, boxes, magnetic tools, notebook and so on |

|

| Different Shapes of Magnets |

Can I customize products?

Yes, Custom Magnets Are Available.

Please tell us the size, grade, surface coation and quantity of the magnet, you will get the most reasonable quotation quickly.

|

Here are some regular magnet sizes for reference

|

1. Custom Size -- ( Please noted all size in mm or inch )

- Round Magnet: Diameter x Height

- Ring M agnet : Outer Diameter x Height - Inter Diameter

- Block M agnet : Length x Width x Height

- Special Shape Magnet: Drafts or drawings will be appreciated

2. Custom Magnet Shape -- ( According to your requirements )

- Disc, Ring, Round, Block, Bar, Countersunk, Triangle, Segment/Tile/Arc, Cylinder, Trapezoid, Fan-shape, irregular shape customize etc

3. Grade Choose -- ( The higher the performance level, the stronger the magnetism )

- N35, N38, N40, N42, N45, N48, N50, N52 (Max Working Temperature 80°C)

- N35M - N50M (Max Working Temperature 100°C)

- N33H - N52H (Max Working Temperature 120°C)

- N30SH - N50SH (Max Working Temperature 140-150°C)

- N35UH - N48UH (Max Working Temperature 170-180°C)

- N28EH - N42EH, N30AH (Max Working Temperature 200-230°C)

4.Surface Coation -- ( Zn and Ni-Cu-Ni coating is the most popular coating )

- Zinc, Nickel, Nickel+Copper+Nickel, Gold, Epoxy, Nickel+Epoxy coating

5. Quantity -- ( Samples are available )

- In order to quote the exact competitive price,the quantity for magnet is essential.

| Magnet Details |

1. Size Tolerance ( +/-0.05mm )

a. Before grinding and cutting, we inspect the black product tolerance.

b. Before and after coating, we will inspect the tolerance by AQL standard.

c. Before delivery, will inspect the tolerance by AQL standard.

PS: Product size can be customized.

2. Surface Treatment

Q: Do neodymium magnets require surface treatments?

A: Yes. If magnets are without surface coating (also named plating), it may rust easily under humid conditions.

There have many plating options like Ni-Cu-Ni, Nickel, Zinc, Gold, Black Epoxy, White Epoxy coating and so on.

Zn and Ni-Cu-Ni coating are the most popular coating. The magnet with plating will resist the corrosion effectively.

3. Magnetization Direction:

Why Choose Us ?

1. Professional magnet manufacturer

2. Outstanding quality

3. Exquisite design

4. Performance surpasses expectations

5. Impeccable packaging

6. On time delivery

We provide excellent service with prompt responses and efficient processes, ensuring every order is processed with precision and care.

| Customer Reviews |

WORLD -WIDE CUSTOMERS COMMENTS & FEEDBACK

Here is some of comments from our world-wide customers.

You can also check all the comments at our company profile.

[ TRUST YOU WILL LIKE OUR SERVICES AND QUALITY ]

| Manufacturing Process |

| Quality Control |

1> Magnet will be inspected strictly during the production of every process.

2> Every magnet will have a certificate before delivery.

3> Magnetic Flux report and Demagnetization Curve can be offered according to request.

Depending on international quality rules and advanced inspection facilities, Jin Tong can achieve comprehensive inspections for the products, to ensure that each product satisfies customers.

DEMAGNETIZATION CURVE