- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/415V/440V( as client request)

-

Dimension(L*W*H):

-

As per different model

-

Weight:

-

2200 KG, 6.5-10T

-

Marketing Type:

-

New Product 2023

-

Product name:

-

Small gold mining trommel screen factory supplier

-

Model:

-

gold mining trommel screen

-

Power:

-

5.5KW, 7.5KW, 11KW

-

Dimension:

-

depends on model

-

Application:

-

alluvial gold washing, diamond, rock, soil, river gold

-

Capacity:

-

30-150 tons per hour

-

Feeding size:

-

less than 300mm

-

Discharge size:

-

less than 6mm

-

Color:

-

yellow, white, red, blue, gray( or as client request)

Quick Details

-

Production Capacity:

-

98%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Sinolion

-

Voltage:

-

380V/415V/440V( as client request)

-

Dimension(L*W*H):

-

As per different model

-

Weight:

-

2200 KG, 6.5-10T

-

Marketing Type:

-

New Product 2023

-

Product name:

-

Small gold mining trommel screen factory supplier

-

Model:

-

gold mining trommel screen

-

Power:

-

5.5KW, 7.5KW, 11KW

-

Dimension:

-

depends on model

-

Application:

-

alluvial gold washing, diamond, rock, soil, river gold

-

Capacity:

-

30-150 tons per hour

-

Feeding size:

-

less than 300mm

-

Discharge size:

-

less than 6mm

-

Color:

-

yellow, white, red, blue, gray( or as client request)

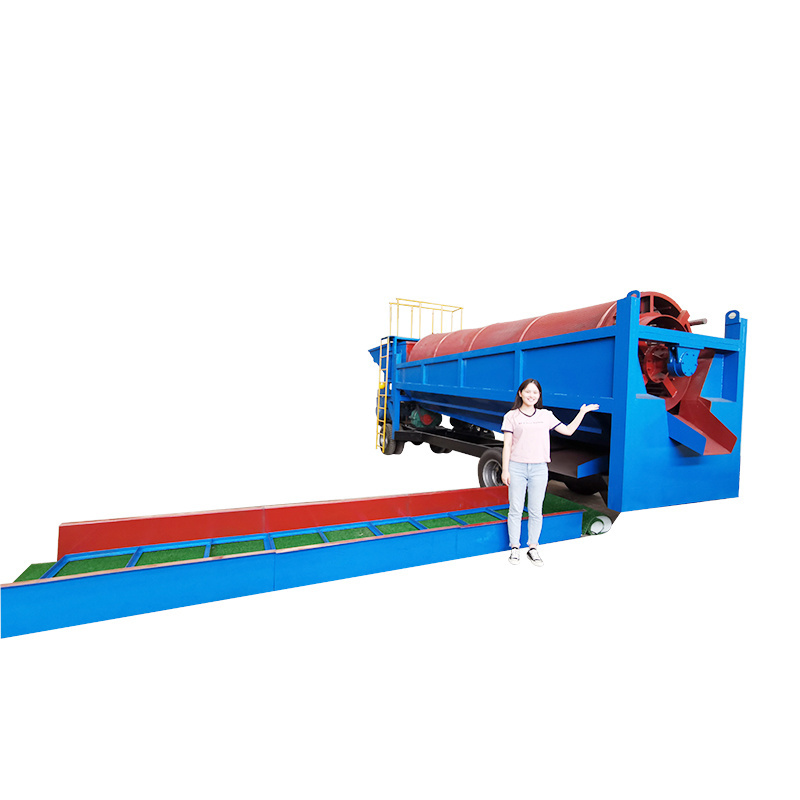

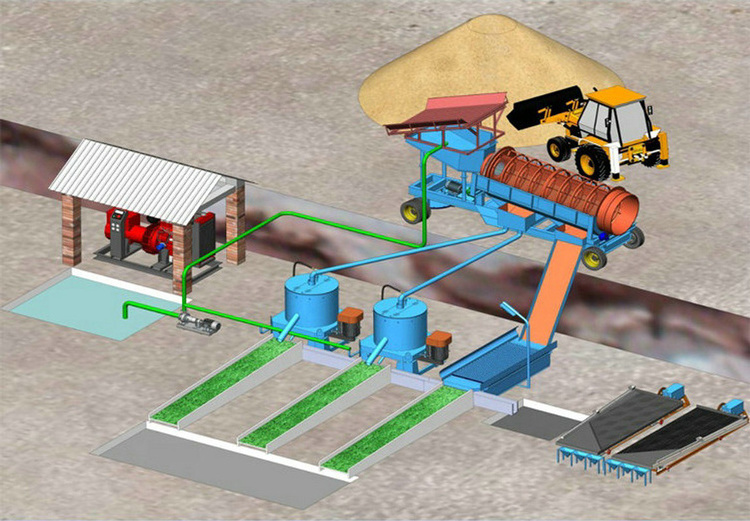

Mini Small Mobile Sand Gold Mining Trommel Wash Plant Factory Supplier

The gold machine movement is very convenient and can be applied to a variety of terrain, terrain is soft sandy or hard rock, stone or more can be applied, and must also very convenient, can satisfy the development of mining while walking. This method has a good effect on a large range of sand gold mining areas, which can save more production costs and increase mining efficiency.

Outstanding Advantages:

:

1.Barrel of trommel screen includes infeed diverter rings for minimizing the material loss.

2.Modular replaceable screen segments according to customer requirements. Customer choose woven wire and plate per their demands.

3.Trommel screens allow access to screens for maintenance and inspection.

4.Alternative discharge belt conveyor, can supply diverse belt conveyor for discharging material of after screened.

5.The main frame of heavy steel structure is designed with components for minimizing material accumulation.

6.Heavy duty structure includes integrated leveling system, it is easy to install.

7.Nylon bristle, cleaning device can be changeable quickly and individually for minimizing downtime of equipment, and that improving efficiency.

8.Trunnion components mounted to heavy duty roller bearings to prolong service life.

9.Low stress welded, structural tubing lifter assemblies

10.Alternative feed and discharge chutes.

|

Model |

Capacity (t/h) |

Capacity (t/h) |

Diameter (mm) |

Length (mm) |

Discharge (mm) |

Input (mm) |

Dimension ((mm) |

|

GMTS0519 |

5-10 |

5-10 |

500 |

1910 |

0-100 |

≤300 |

3000x1000x1800 |

|

GMTS1020 |

10-30 |

10-30 |

1000 |

2000 |

0-100 |

≤300 |

3390×1400×2140 |

|

GMTS1225 |

30-50 |

30-50 |

1200 |

2500 |

0-100 |

≤300 |

4146×1600×2680 |

|

GMTS1548 |

80-150 |

80-150 |

1500 |

4800 |

0-100 |

≤400 |

8460×2300×2500 |

|

GMTS1848 |

100-200 |

100-200 |

1800 |

4800 |

0-100 |

≤400 |

8460×2300×2700 |

|

GMTS2060 |

200-350 |

200-350 |

2000 |

6000 |

0-100 |

≤400 |

9680×2300x3420 |