- Product Details

- {{item.text}}

Quick Details

-

Power:

-

740KW

-

Weight:

-

200000 KG

-

Dimension(L*W*H):

-

4950*800*1900CM

-

Product name:

-

Flour Milling Machine

-

Raw material:

-

Wheat Maize Corn Rice Grain

-

Function:

-

Multifunction Flour Grinder

-

Final products:

-

Super Fine Flour

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jianxin

-

Voltage:

-

380V

-

Power:

-

740KW

-

Weight:

-

200000 KG

-

Dimension(L*W*H):

-

4950*800*1900CM

-

Product name:

-

Flour Milling Machine

-

Raw material:

-

Wheat Maize Corn Rice Grain

-

Function:

-

Multifunction Flour Grinder

-

Final products:

-

Super Fine Flour

|

Model |

Power |

Power Consumed Of One Ton Flour |

Capacity |

Overall Dimension(L*W*H) |

|

No. |

(KW) |

(KW/H) |

(Ton/24h) |

(M) |

|

10 |

560 |

68~72 |

140 |

41*7.5*19 |

|

11 |

650 |

68~72 |

160 |

47*7.5*19 |

|

12 |

740 |

65~71 |

200 |

49*7.5*19 |

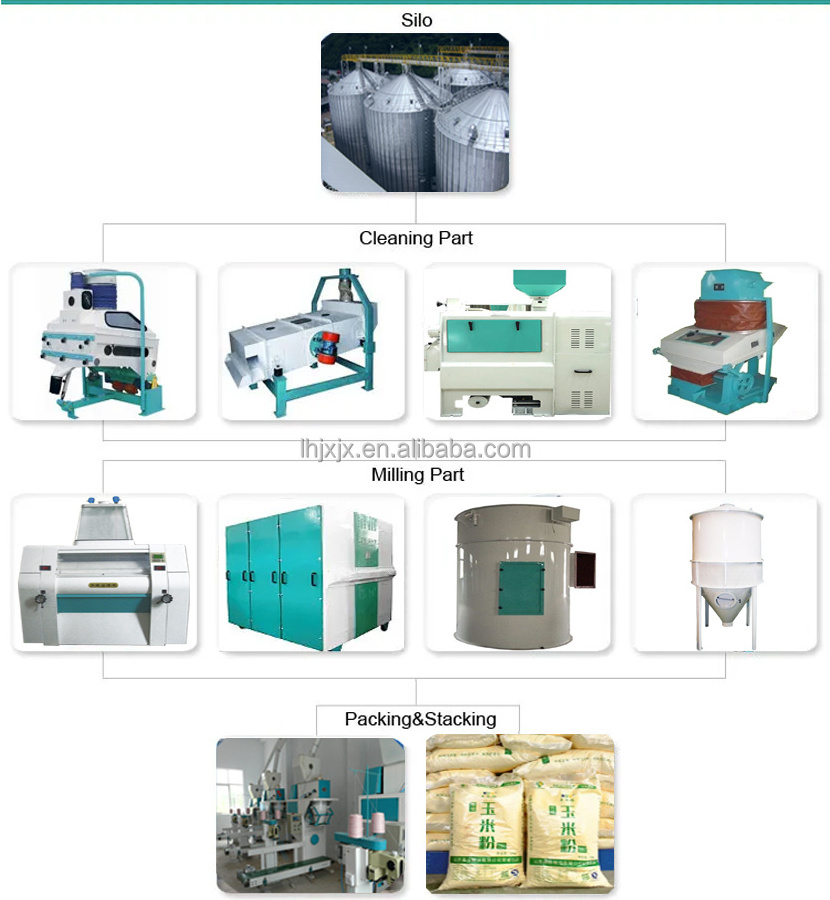

200 tons per day m aize flour mill plant

Corn milling plant or maize flour milling plant

adopts dry method and excellent automation solution, and furthest reduces manual cost and production cost. The professional corn processing project designers and commissioning engineers team ensures the technological advancement, which not only reduces energy consumption, but also reduces the impurities, dust and bran speck impact to end products.

Quality goods yield rate reaches or surpasses national standard and increases market competitiveness. The whole maize milling plant or corn flour milling plant has the features of advanced technology, superior equipment, strong specificity, reasonable arrangement, low energy consumption, high flour yield and so on. It is widely used in the following enterprises: food, sugar, beer and so in. And the core equipments have gained national patent.

Corn milling plant or maize milling plant technological introduction:

1. Maize milling plant first removes impurities mixed with the corn kernels: one classifying process can sort out qualified size of corn kernels; one polishing machine can remove the impurities which adhere to the kernel surface and make kernels look more bright.

2. Unprocessed corn cleaning section: it adopts one screening process, one stone removing process and the winnowing system to clean the big and small impurities, light impurities, pebbles and magnetic material to ensure the product quality.

3. Flour milling section: smashing makes the material granularity suitable when it enters into the flour milling machine so as to improve grinding efficiency. The flour milling machine can grind the material into flour, then the screen separates various material. Purification can separate the fine skin and broken germs by the combined effect of screening and winnowing.

4. Measuring and packaging section: the warehouse can reduce the amount of labour used. Measuring and packaging can adopt manual or electrical measuring and packaging according to actual needs.

Corn milling plant technical parameter:

1. End products: grade corn flour and corn bran.

2. Products yield rate: grade corn flour 75-80%, corn bran 20-25%

3.End products index:

A. Corn flour fineness:

40-200 meshes (the flour fineness can be adjusted)

B. Sand content:

<0.02%

C. Magnetic metal content:

< 0.003/kg

D. Moisture storage:13.5-14.5%

E. Fat content:0.5—1%

F. Appearance and taste: bright and golden color, fine powder, high quality and pure taste.

Core equipments: vibrating sieve, classifying destoner machine, air blower, air suction duct, degerminator, germ extraction machine, corn peeling machine, corn polishing machine, flat sieve.

Advantages of the corn milling plant or corn flour milling palnt:

1. It reduces equipment input in grain dampening and end products drying compared to the wet method technology.

2. Corn dry method processing technology makes the processing more sanitary.

Jianxin Machinery supplies you with the professional project consulting and service programme:

1. Corn and grain varieties in different areas may need different engineering demand plans.

2. On receipt of your order, our sales manager and engineers project team will provide you with the most professional technical guidance.

Pre-sales & Scheme

We provide professional design according to the requirements of your products. We will offer you reasonable recommendations and optimal solutions to guarantee the overall performance of the machine so as to ensure your entire production process and the quality of your products.

Equipment Installation and Training

We have professional installation technicians provide installation and training services for your workers. It will be helpful to guarantee the normal operation of the equipment and reduce its downtime.

F i xing and Services

We have specialized technology department and after-sales service department to provide you with reliable pre-sales service and timely thoughtful after-sales service.We will do regular examinations to the equipment and offer you guidance on the equipment operation if you need. Spare Parts Supply

In your first order, we will send you some wearing parts available for two-years operation of the equipment. Online procurement for parts is available when the equipment is in operation.We will supply wearing parts with factory price for old customers.