- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Model Choosing

-

Weight:

-

Model Choosing

-

Dimension(L*W*H):

-

Model Choosing

-

Warranty:

-

12 Months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Description:

-

2 Phase Sludge Dewatering Decanter Centrifuge

-

MOC:

-

SS304, SS316

-

Speed:

-

Inverter control

-

Bearing:

-

SKF

-

Discharging type:

-

Partial discharge, self-cleaning

-

Motor:

-

2

-

Electrical components:

-

World famous brand

-

Operation:

-

Continuous

-

Separation phase:

-

Two phase

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

ISO

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Kingreat

-

Voltage:

-

220V/380V....

-

Power:

-

Model Choosing

-

Weight:

-

Model Choosing

-

Dimension(L*W*H):

-

Model Choosing

-

Warranty:

-

12 Months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Description:

-

2 Phase Sludge Dewatering Decanter Centrifuge

-

MOC:

-

SS304, SS316

-

Speed:

-

Inverter control

-

Bearing:

-

SKF

-

Discharging type:

-

Partial discharge, self-cleaning

-

Motor:

-

2

-

Electrical components:

-

World famous brand

-

Operation:

-

Continuous

-

Separation phase:

-

Two phase

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

ISO

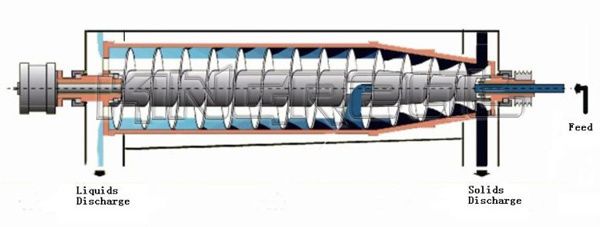

Horizontal 2 Phase Sludge Dewatering Decanter Centrifuge

Whole waste water treatment includes sludge feeding system,flocculant adding system,dewatering system,filter cake delivery system and PLC control system.

The main equipment of sludge dewatering complete system is decanter centrifuge. There are basically two application types in the wastewater treatment industry for the decanter centrifuge: sludge thickening and sludge dewatering duties. Also it can be used for Sludge classification and Sludge clarification. With the decanter centrifuge,it is possible to separate the particles from suspending liquid with equivalent diameter bigger than 0.003mm,solid-liquid weight ratio less than 10% or volume ratio less than 70%,difference in specific gravity bigger than 0.05g/cm3.

Sludge dewatering complete system could be used in the following fields:

Municipal sludge treatment,paper mill sludge,starch factory waste water treatment,stell mill sludge,printing and dyeing mill sludge,water works sludge,pharmaceutical waste sludge,PVC sludge,sewage desulfurization sludge,grain stillage,power plant ash sludge,dairy sludge,beer sludge,drilling fluid ,electroplating liquid,fermented liquid manure,oil refining sludge,soap sludge,leather sludge and etc.

|

Model |

Diameter (mm) |

Bowl speed (rpm) |

Length (mm) |

G-force |

Capacity (m3/h) |

Main motor power (kw) |

Assistant motor power (kw) |

Weight (kg) |

Overall size (L × W × H) (mm) |

|

PNX409 |

250 |

5500 |

850 |

3493 |

0.2-2 |

15 |

4 |

1020 |

2500 × 650 × 760 |

|

PNX-414 |

355 |

4000 |

860 |

3175 |

1~10 |

18.5 |

7.5 |

2035 |

2765 × 920 × 1060 |

|

PNX-416 |

355 |

4000 |

1160 |

3175 |

1~15 |

18.5 |

7.5 |

2122 |

3065 × 920 × 1060 |

|

PNX-418 |

355 |

4000 |

1460 |

3175 |

1~25 |

22 |

7.5 |

2222 |

3365 × 920 × 1060 |

|

PDC-1655 |

420 |

3000 |

1450 |

2113 |

10~30 |

55 |

15 |

4600 |

4080 ×1100 × 1420 |

|

PDC-17-4 |

420 |

3600 |

1680 |

3042 |

3~15 |

30 |

7.5 |

5165 |

3331 × 990 × 1066 |

|

PDC-18-4.4 |

450 |

3300 |

2000 |

2739 |

10~20 |

37 |

11 |

2739 |

4000 × 1120 × 1239 |

|

PDC-20 |

500 |

3200 |

2000 |

2860 |

5~45 |

55 |

11 |

4400 |

4489 × 1160 × 1350 |

|

PDC-21 |

540 |

2800 |

2000 |

2366 |

15~50 |

45 |

15 |

5290 |

4587 × 1285 × 1368 |

|

PDC-24 |

620 |

3200 |

2480 |

3555 |

15~60 |

Hydraulic station 90 |

8000 |

4650 × 2010× 1200 |

|

|

PDC-28HH |

720 |

2200 |

2400 |

1975 |

15-80 |

110 |

37 |

9393 |

4800 ×1350 × 1500 |