- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

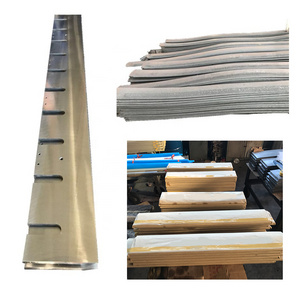

Wood Chipper Blade

-

Material:

-

SKD11, Cr12MoV, H12, etc.

-

Precision:

-

±0.02mm

-

Hardness:

-

58-60 HRC

-

Packing:

-

Wooden Box

-

Key words:

-

Wood Chipper Knife

-

Sharpness:

-

18N~30N

-

MOQ:

-

1 Pc/1 Set

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Weight (KG):

-

20 KG

-

Application:

-

Wood Planer Blade

-

Product name:

-

Wood Chipper Blade

-

Material:

-

SKD11, Cr12MoV, H12, etc.

-

Precision:

-

±0.02mm

-

Hardness:

-

58-60 HRC

-

Packing:

-

Wooden Box

-

Key words:

-

Wood Chipper Knife

-

Sharpness:

-

18N~30N

-

MOQ:

-

1 Pc/1 Set

Products Description

Introduction:

Crusher blades are also called crusher blades, with a wide variety of specifications. The blade material is made of

high-quality steel (9Crsi, 6CrW2si, Cr12MoV, SKD-11 blade insert alloy, etc.) with good sharpness and wear resistance.

The shredder blades are mainly used for various PE PA PVC ABS plastic plates, rubber plates, tires, straws, waste recycling

and other materials. The shredder blades adopt a good heat treatment process. The blades have the advantages of clustering, abrasion resistance and not easy to collapse.

Advantages:

1. Various dimensions are available.

2. Material of high precision tool steel D2, M2, ASP, High Speed Steel etc. We choose, test and apply the premium quality raw

material to produce plastic crusher knife/blade.

3. High hardness, super cutting quality, durable sharpness, long wear life.

4. Competitive price, well accepted by our customers.

5. Availability in stock, plastic crusher blades can be sent to our customers in a short time.

6. Door to Door, fast and convenient delivery service, provided by DHL, FedEx, UPS, TNT, EMS etc.

7. OEM service is always available. Please feel free to tell us the requirement and specification of your plastic crusher

knife/blade.

2. Material of high precision tool steel D2, M2, ASP, High Speed Steel etc. We choose, test and apply the premium quality raw

material to produce plastic crusher knife/blade.

3. High hardness, super cutting quality, durable sharpness, long wear life.

4. Competitive price, well accepted by our customers.

5. Availability in stock, plastic crusher blades can be sent to our customers in a short time.

6. Door to Door, fast and convenient delivery service, provided by DHL, FedEx, UPS, TNT, EMS etc.

7. OEM service is always available. Please feel free to tell us the requirement and specification of your plastic crusher

knife/blade.

|

Specification

|

|

|

|

Size

|

Customized

|

|

|

Material

|

HSS, 9CrSi, 6CrW2Si,H13 , SKD11, LD, D2 and etc.

|

|

|

Hardness

|

58-60 HRC

|

|

|

Tolerance

|

Exceed OEM specification

|

|

|

OEM Service

|

Available

|

|

|

Packing

|

Wooden boxes, standard export packaging

|

|

|

Application

|

Crusher blades for Plastic, Rubber, Metal, Waste Recycling

|

|

|

Delivery time

|

30 days after deposit be received

|

|

Product Paramenters

Custom notice

1.Before ordering,please measure the size of the old knife (draw a sketch) and contact customer service. After confirming that the size of the blade is correct, select the appropriate blade material and price. After confirmation, place the order and start production.

2.Blade measurement method (

See picture above)

Fine workmanship, fine surface grinding

The surface is finely ground to reduce the friction of the cutting, making the cutting more effortless and the cutting surface smoother

Internal hole positioning,

Accurate hole location

Using CNC flame cutting machine to process the inner hole, the precision is more accurate, and it is not easy to shake after installation

Delicate

opening

,

Sharp edge

The use of CNC grinding machine processing, making the cutting edge more sharp, smooth cutting

Wooden packing

Easy to transport

It is packed in wooden case, which does not damage the blade edge during transportation, and does not affect the normal storage of other blades when it is disassembled, so it is not easy to rust

Hot Searches