- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

XKJ

-

Dimension(L*W*H):

-

812x982x785

-

Weight:

-

800 KG

-

Warranty:

-

12 months except wearing parts

-

Material:

-

As per industrial standard

-

color:

-

up to you

-

company experience:

-

more than 25 years

-

spare parts:

-

supply in long term

-

operation:

-

easy and simple

-

working condition:

-

continuous and reliable

-

price:

-

reasonable and competitive

-

Max feeding size (mm):

-

80

-

quality control:

-

through five steps before delivery

-

Discharge size (mm):

-

10

Quick Details

-

Application:

-

quarry, mineral,construction,

-

Capacity(t/h):

-

5-8

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XKJ

-

Dimension(L*W*H):

-

812x982x785

-

Weight:

-

800 KG

-

Warranty:

-

12 months except wearing parts

-

Material:

-

As per industrial standard

-

color:

-

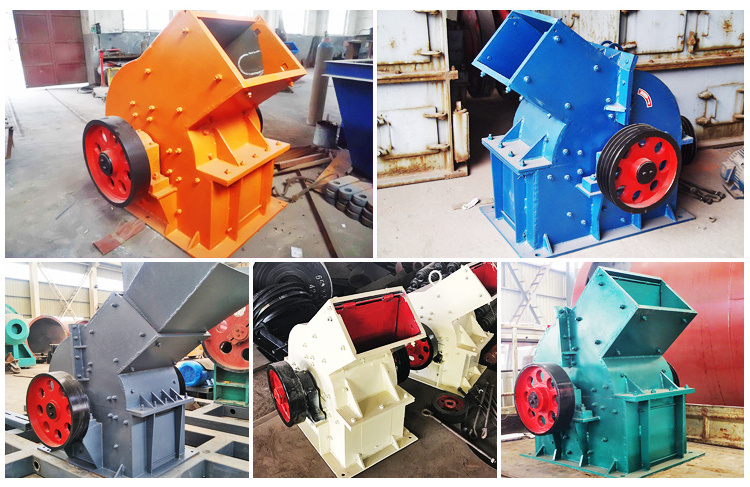

up to you

-

company experience:

-

more than 25 years

-

spare parts:

-

supply in long term

-

operation:

-

easy and simple

-

working condition:

-

continuous and reliable

-

price:

-

reasonable and competitive

-

Max feeding size (mm):

-

80

-

quality control:

-

through five steps before delivery

-

Discharge size (mm):

-

10

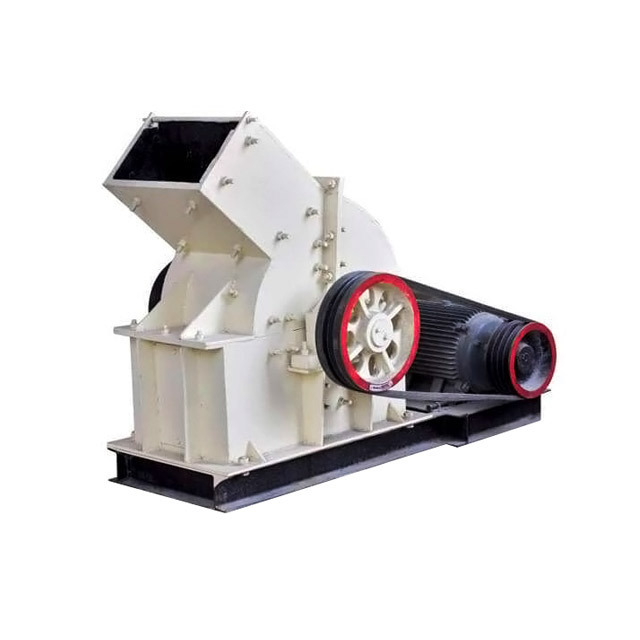

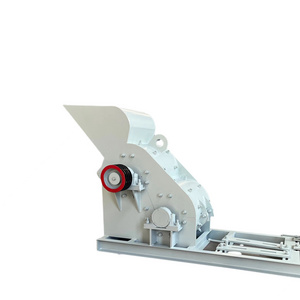

1. Main Characteristics of Hammer mill Crusher

(1). Adjustable output size.

(2). Adopting patent hammer head with all-round using.

(3). Reversible adjustable plate, longer longevity, easier adjustment.

(4). Adopting spring device, reliable and safe.

(5). No abrasion in the heart of rotor or frame except the hammer head comparing to traditional hammer crushing and impact crushing.

(6). Easy maintenance and repair. No need to hang up the upper box but opening the front door of downward box.

(7). Adopting extra large practical rotor, strong inertia rotation, heavy hitting power, no blocking when power off.

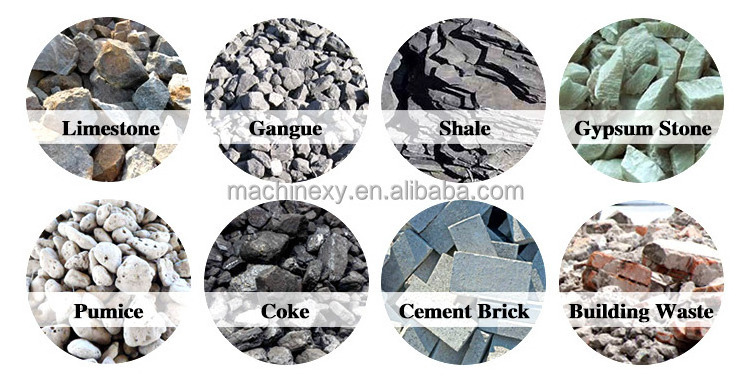

2.Application of Hammer mill crusher

Hammer crusher were developed for the both dry and wet crushing of brittle, medium-hard materials for the mining, cement, coal, metallurgic, constructionmaterial, road building, and Petroleum & Chemical industries.

Hammer crusher is applicable for crushing of brittle minerals, such as coal, salt, plaster, alum, brick, tile and limestone with compression strength no more than 100mpa and humidity no more than 15%. The hammer crusher also called crusher machine, stone crusher, widely used in mining and quarring industry.

PC400X300 delivery to India:

PC400X300 Delivery to Japan:

3.The operating principle of Hammer mill Crusher

The motor drives the rotor rotate of the hammer crusher at a high speed through the belt. The materials are sent into the entrance of the hammer crusher .

Hammer mill crusher structure:

They are crushed by the high speed hammer from blowing, impacting, cutting, grinding. Below the rotor, there are sieves, the little size products among the crushing products can be discharged through the sieve. The large size products are brought back to the crushed area by the hammer from blowing and grinding until they reached the required size. At last, they are discharged through sieve.

4.Technical Parameters of Hammer Crusher

|

Model |

Rotor speed (r/min) |

Feed opening size (mm) |

Max feeding size (mm) |

Discharging size (mm) |

Capacity (t/h) |

Motor power (kw) |

Weight (t) |

Overall dimensions L×W×H (mm) |

|

PC400×300 |

1500 |

145×295 |

100 |

0-30 |

5-8 |

7.5 |

0.9 |

844×942×878 |

|

PC600×400 |

1000 |

295×450 |

100 |

0-35 |

10-12 |

18.5 |

1.5 |

1000×1000×1300 |

|

PC600×600 |

1000 |

295×570 |

100 |

0-35 |

12-18 |

45 |

2.14 |

1315×840×1501 |

|

PC800×600 |

1000 |

350×570 |

120 |

0-45 |

20-25 |

55 |

2.45 |

1515×2586×1040 |

|

PC800×800 |

1000 |

350×850 |

120 |

0-45 |

35-45 |

55 |

3.05 |

1515×2831×1040 |

|

PC1000×800 |

1000 |

580×580 |

200 |

0-45 |

25-40 |

110 |

6.5 |

3206×2210×1515 |

|

PC1000×1000 |

1000 |

580×1060 |

200 |

0-45 |

40-80 |

132 |

7.59 |

3514×2230×1515 |

|

PC 1250×800 |

750 |

650×850 |

200 |

0-45 |

20-50 |

132 |

11.7 |

2630×1780×2050 |

|

PC1250×1250 |

750 |

650×1330 |

200 |

0-45 |

90-110 |

185 |

13.2 |

2630×2180×2050 |

|

PC1400×1400 |

750 |

1050×1540 |

250 |

0-45 |

120-170 |

280 |

17.2 |

2790×2800×2310 |

|

PC1600×1600 |

600 |

1500×1785 |

350 |

0-60 |

220-280 |

450 |

22.8 |

3350×3120×2660 |

Note: The above technical parameters are just for reference, if you want to get more detailed information or if you have any trouble in selecting the suitable machine, please contact us.

Main spare parts of hammer crusher:

Rotor:

Hammer head: