- Product Details

- {{item.text}}

Quick Details

-

Working area:

-

1300x2500*200mm, 4*8 feet

-

Control system:

-

Wehong 95A-3L

-

Spindle:

-

3.5/4.5kw HQD/HSD air cooled spindle

-

Transmission:

-

Taiwan HIWIN 20mm 25mm guide rails, Taiwan TBI Ball Screw

-

Drive motor:

-

Leadshine 750w servo motor driver

-

Inverter:

-

Fuling Inverter

-

Table:

-

Aluminum table

-

Dust collection:

-

double bag dust collection

-

After-sales Service Provided:

-

Field maintenance and repair service

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

China

-

Product name:

-

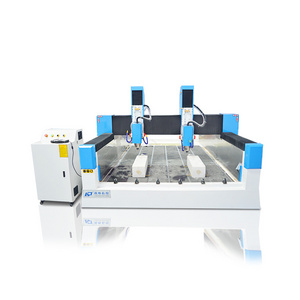

Multi head drilling cnc wood carving machine router with good price

-

Feature:

-

3/4process spindle,3/4 different change tool

-

Working area:

-

1300x2500*200mm, 4*8 feet

-

Control system:

-

Wehong 95A-3L

-

Spindle:

-

3.5/4.5kw HQD/HSD air cooled spindle

-

Transmission:

-

Taiwan HIWIN 20mm 25mm guide rails, Taiwan TBI Ball Screw

-

Drive motor:

-

Leadshine 750w servo motor driver

-

Inverter:

-

Fuling Inverter

-

Table:

-

Aluminum table

-

Dust collection:

-

double bag dust collection

-

After-sales Service Provided:

-

Field maintenance and repair service

-

Certification:

-

CE ISO

Multi head drilling cnc wood carving machine router with good price

Machine Parameters:

|

Working Area

|

1300*2500mm ( can be customized)

|

|

Z axis Feeding Height

|

180mm( can be customized )

|

|

Spindle Model

|

3 x 3.5/4.58kw water cooling spindle (Air cooling optional)

|

|

Moving System

|

Leadshine Servo motors and drivers

|

|

Control System

|

Wehong 95A-3L |

|

X Y axis transmission

|

Gear and Rank

|

|

Z axis transmission

|

Ball screw

|

|

Rails

|

X Y Z axis Hiwin Linear Square Rails

|

|

Table

|

Aluminum table

|

|

Motion Positioning Accuracy

|

± 0.03mm

|

|

Repositioning Accuracy

|

± 0.05mm

|

|

Z-axis setting

|

Auto Z origin tool high sensor

|

|

Voltage

|

220V/380V

|

|

Software

|

ArtCAM software

|

|

Optional Parts

|

Dust Collect

Stainless Water tank and Water pump

Rotary for cylinder materials

|

Features:

1.Adopt High strength welded bed with tempering aging treatment, Five sides milling CNC machining center processing, guarantees rigidity and precision of the machine,cutting or carving won't vibration.

2.Chinese HQD spindle or Italian HSD ATC air cooling spindle, ensure the cutting effect, long using life with less maintain.

Three tool changer will greatly improve the work efficiency for processing wood Furniture.

3. Servo system to make sure speed and stability. It runs smoothly ,no vibration phenomenon even in low speed and has overload ability,servo is more reliable and better than stepper.

4. gantry type movement, strengthened table top, strong and durable, no deformation after long-term use, making positioning accuracy more accurate.

5.Wehong 95A-3L control system

6. fully supports iso standard g instruction and eng format, and is compatible with machining codes generated by various CAD / cam design software such as type 3 / artcam / cast mate / Wen Tai

Application&Samples:

Wooden door and furniture decoration industry:

Solid wood door, compound door, cupboard door, large area plank plane carving, wood carve designs, board type furniture engraving, archaize annatto furniture engraving, solid wood art mural engraving and so on.

1. Wooden crafts processing:

Clock frame, picture frame, calligraphy plaque, electrical counter face, sports equipment, thin aluminum board cutting and engraving.

2. Electronic product industry:

Circuit board, insulation materials, the LED display, home appliance (color TV sets, washing machines, refrigerators) shell or model engraving and cutting;

3. Instrument industry:

Engraving instruments 3D surface, Appearance cutting, such as cello, violin panel and head; guitar, erhu 3D surface engraving and cutting.

4. EVA processing industry:

EVA packing materials lined engraving and cutting for tool equipment, medical equipment, electronic products, glass vessel.

5. Other industries:

The building model, the block, aviation block, propellers, car foam mold.

Packaging Details

1.Wrapping with water-proof plastic film

2.Packing in a plywood box.

Shipping Details

1. Shipped in 3-20 working days after payment.

2. We usually ship the machine by sea, also, landing and air transportation are also available.

Our Company:

Jinan GoodCut CNC Machinery Co.,Ltd.

GoodCut has been abiding by the “Good quality, Good creation” management philosophy, innovating efficient R&D and management team, having advanced development manufacturing technology, high precision machine part testing equipment and strict norms ISO9001 quality management system, while the introduction of 5S on-site management to ensure the performance and quality of each machine. Products are sold in more than 90 countries and regions in the world, we strive to create a global fiber laser cutting machine leader.

GoodCut has 31 national patents. The newly developed medium or high power fiber laser cutting machine has high photoelectric conversion efficiency, high cutting speed, high material utilization and stable performance . Fiber cutting is the industry trend and it will lead a new era of cutting industry.