- Product Details

- {{item.text}}

Quick Details

-

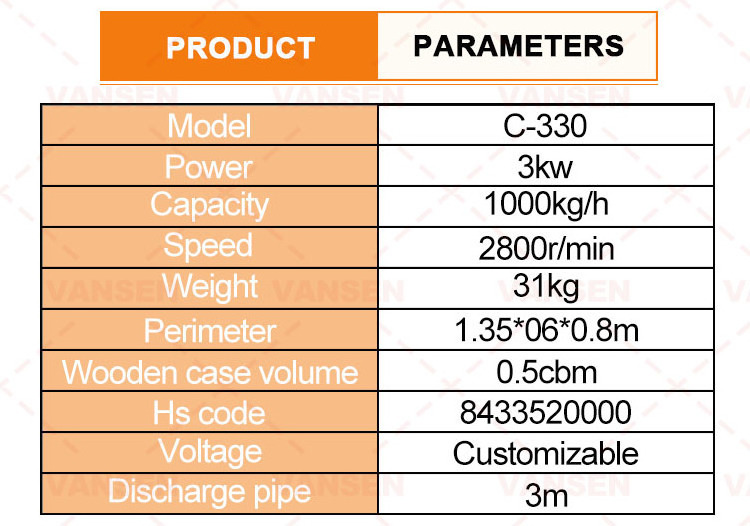

Production Capacity:

-

1000kg/h

-

Place of Origin:

-

Henan, China

-

Voltage:

-

Customizable

-

Dimension(L*W*H):

-

630*330*650mm

-

Weight:

-

31 KG

-

Application:

-

Corn

-

Function:

-

Corn Maize Threshing

-

Raw material:

-

Corn,maize

-

Power:

-

3kw

-

Color:

-

Customer Inquirments

-

Shelling rate:

-

95~99%

-

Model:

-

VS-C330

-

Packing:

-

Wooder Case

-

Final products:

-

Corn grain

-

MOQ:

-

1 Set

Quick Details

-

Marketing Type:

-

New Product 2022

-

Type:

-

Agriculture Machine

-

Use:

-

Corn Sheller

-

Production Capacity:

-

1000kg/h

-

Place of Origin:

-

Henan, China

-

Voltage:

-

Customizable

-

Dimension(L*W*H):

-

630*330*650mm

-

Weight:

-

31 KG

-

Application:

-

Corn

-

Function:

-

Corn Maize Threshing

-

Raw material:

-

Corn,maize

-

Power:

-

3kw

-

Color:

-

Customer Inquirments

-

Shelling rate:

-

95~99%

-

Model:

-

VS-C330

-

Packing:

-

Wooder Case

-

Final products:

-

Corn grain

-

MOQ:

-

1 Set

Product Instructions

|

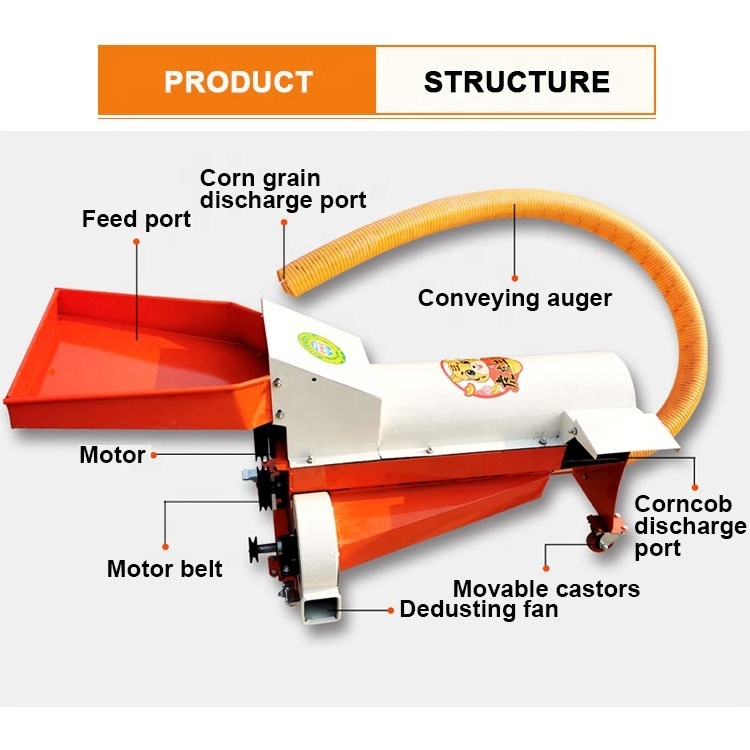

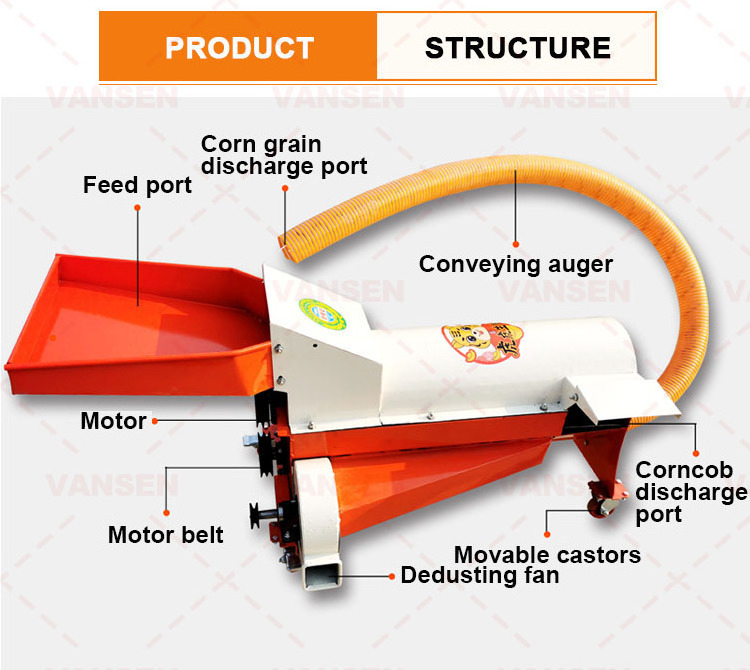

Small mini manual mobile electric sweet dry corn maize threshing thresher sheller machine

|

Introduce

Corn thresher refers to a mechanical device that threshes corn ears. The corn thresher has the characteristics of high automation, strong security, simple operation and low energy consumption.

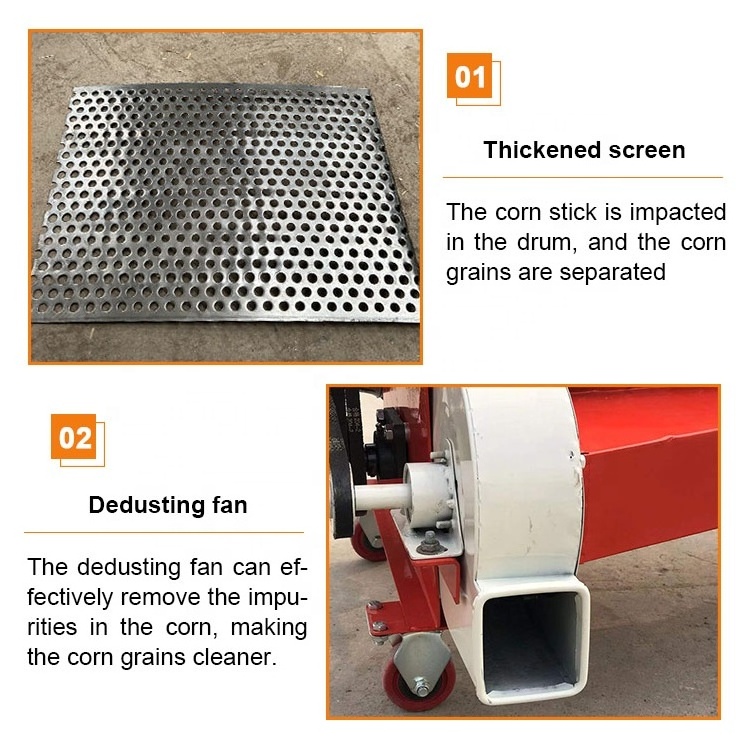

The corn thresher is mainly composed of a drum, a concave plate, a sieve, a fan, a feeding hopper, a seed slide plate, a spiral guide rod, etc. The utility model adopts an axial flow threshing device which tangentially feeds the ear row shaft at the shaft end. Its technological process: corn ears enter the drum through the feeding hopper, and are threshed under the impact of high-speed rotary drum and the interaction of corn ears, drum and concave. Most of the removed grains and small impurities pass through the concave holes and are cleaned by the fan. The light impurities are blown out from the trash outlet, and the grains slide out of the machine by the grain slide plate. The spike shaft moves backward along the axial direction of the drum, and is discharged from the machine through the outlet of the shaft end through the surface of the vibrating screen. Some grains carried in the spike shaft leak through the screen hole and enter the grain slide plate to slide out of the machine.

Technical Parameter

Product Structure

Product details

Product Advantages

Our Factory

Contact Us

Hot Searches