- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

2000*1300*3010mm

-

Motor Power (kW):

-

7.5

-

Model Number:

-

JH21-100

-

Weight (T):

-

8.65

-

Product name:

-

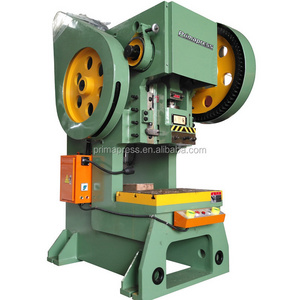

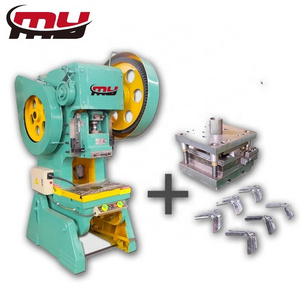

JH21-100 Ton C Frame Mechanical Bearing Press Machine

-

Application:

-

Metal Sheet Stamping

-

Press body:

-

C frame steel welded

-

Press clutch type:

-

Wet type pneumatic clutch

-

Control system:

-

PLC(Touch Screen)

-

Press stroke speed:

-

55spm

-

Press stroke length:

-

160mm

-

Press lubrication system:

-

Auto grease pump

-

Weight:

-

8650kg

Quick Details

-

Slide Stroke (mm):

-

160

-

Place of Origin:

-

China

-

Brand Name:

-

WORLD

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

2000*1300*3010mm

-

Motor Power (kW):

-

7.5

-

Model Number:

-

JH21-100

-

Weight (T):

-

8.65

-

Product name:

-

JH21-100 Ton C Frame Mechanical Bearing Press Machine

-

Application:

-

Metal Sheet Stamping

-

Press body:

-

C frame steel welded

-

Press clutch type:

-

Wet type pneumatic clutch

-

Control system:

-

PLC(Touch Screen)

-

Press stroke speed:

-

55spm

-

Press stroke length:

-

160mm

-

Press lubrication system:

-

Auto grease pump

-

Weight:

-

8650kg

|

Item

|

|

Code

|

Unit

|

JH21-25

|

JH21-45

|

JH21-60

|

JH21-80

|

JH21-100

|

JH21-125

|

|

|

Nominal Capacity

|

|

Pe

|

kn

|

250

|

450

|

600

|

800

|

1000

|

1250

|

|

|

Slide Stroke Length

|

|

S

|

mm

|

80

|

120

|

140

|

160

|

160

|

180

|

|

|

Slide Strokes

|

Fixed

|

|

spm

|

100

|

80

|

70

|

60

|

55

|

50

|

|

|

|

Variable (optional)

|

|

spm

|

60-120

|

50-95

|

45-85

|

40-75

|

35-65

|

35-65

|

|

|

Max. Die Shut Height

|

|

H2

|

mm

|

250

|

270

|

300

|

320

|

335

|

350

|

|

|

Die Shut Height Adjustment

|

|

t

|

mm

|

50

|

60

|

70

|

80

|

90

|

90

|

|

|

Throat Depth

|

|

C1

|

mm

|

210

|

225

|

270

|

310

|

330

|

350

|

|

|

Distance Between Uprights

|

|

d1

|

mm

|

450

|

515

|

560

|

610

|

670

|

670

|

|

|

Slide Bottom Size

|

FB

|

b

|

mm

|

250

|

340

|

400

|

460

|

520

|

520

|

|

|

|

LR

|

a

|

mm

|

360

|

410

|

480

|

540

|

620

|

620

|

|

|

Shank Hole Size

|

Diameter

|

d

|

mm

|

40

|

50

|

50

|

50

|

70

|

70

|

|

|

|

Depth

|

I

|

mm

|

65

|

60

|

70

|

65

|

90

|

90

|

|

|

Table Size

|

FB

|

D

|

mm

|

400

|

440

|

520

|

600

|

640

|

680

|

|

|

|

LR

|

C

|

mm

|

720

|

825

|

930

|

950

|

1060

|

1100

|

|

|

|

Thickness

|

H3

|

mm

|

80

|

110

|

130

|

140

|

145

|

155

|

|

|

Table Hole Diameter

|

|

¢

|

mm

|

150

|

150

|

150

|

180

|

180

|

200

|

|

|

Overall Specs

|

FB

|

A

|

mm

|

1500

|

1585

|

1540

|

1765

|

2000

|

2040

|

|

|

|

LR

|

B

|

mm

|

945

|

1075

|

1200

|

1200

|

1300

|

1320

|

|

|

|

Height

|

H

|

mm

|

2120

|

2390

|

2570

|

2725

|

3010

|

3035

|

|

|

Motor Power

|

|

|

kw

|

3

|

5.5

|

5.5

|

7.5

|

7.5

|

11

|

|

|

Weight (approximate)

|

|

|

kg

|

2450

|

3550

|

5150

|

6450

|

8650

|

9550

|

|

|

Item

|

|

Code

|

Unit

|

JH21-160

|

JH21-200

|

JH21-250

|

JH21-315

|

JH21-400

|

|

|

Nominal Capacity

|

|

Pe

|

kn

|

1600

|

2000

|

2500

|

3150

|

4000

|

|

|

Slide Stroke Length

|

|

S

|

mm

|

200

|

220

|

220

|

220

|

250

|

|

|

Slide Strokes

|

Fixed

|

|

spm

|

45

|

45

|

30

|

30

|

30

|

|

|

|

Variable (optional)

|

|

spm

|

30-55

|

30-55

|

20-35

|

20-35

|

20-35

|

|

|

Max. Die Shut Height

|

|

H2

|

mm

|

400

|

450

|

500

|

500

|

550

|

|

|

Die Shut Height Adjustment

|

|

t

|

mm

|

100

|

110

|

120

|

120

|

120

|

|

|

Throat Depth

|

|

C1

|

mm

|

400

|

430

|

450

|

450

|

490

|

|

|

Distance Between Uprights

|

|

d1

|

mm

|

736

|

910

|

980

|

980

|

1050

|

|

|

Slide Bottom Size

|

FB

|

b

|

mm

|

580

|

650

|

700

|

700

|

750

|

|

|

|

LR

|

a

|

mm

|

700

|

880

|

950

|

950

|

1020

|

|

|

Shank Hole Size

|

Diameter

|

d

|

mm

|

70

|

70

|

70

|

70

|

70

|

|

|

|

Depth

|

I

|

mm

|

100

|

100

|

130

|

130

|

130

|

|

|

Table Size

|

FB

|

D

|

mm

|

760

|

840

|

880

|

880

|

950

|

|

|

|

LR

|

C

|

mm

|

1175

|

1390

|

1500

|

1540

|

1700

|

|

|

|

Thickness

|

H3

|

mm

|

165

|

180

|

190

|

190

|

210

|

|

|

Table Hole Diameter

|

|

¢

|

mm

|

220

|

240

|

260

|

260

|

280

|

|

|

Overall Dimension

|

FB

|

A

|

mm

|

2305

|

2600

|

2660

|

2720

|

2850

|

|

|

|

LR

|

B

|

mm

|

1420

|

1540

|

1640

|

1680

|

1750

|

|

|

|

Height

|

H

|

mm

|

3215

|

3800

|

3850

|

3850

|

4140

|

|

|

Motor Power

|

|

|

kw

|

15

|

18.5

|

22

|

30

|

37

|

|

|

Weight (approximate)

|

|

|

kg

|

13600

|

19200

|

23200

|

26600

|

29500

|

|

Advantage:

2. The press adopts Panasonic or Omron PLC with high stability and longer service life.

3. The wet cultch produced by World is made up of the best seals, bearing and friction discs. It features lower noise and longer service life.

4. The control panel includes double hand buttons and emergency stop button and foot pedal control switch is optional.

5. The press is equipped with auto lubrication pump and it is easy for maintenance.

6. The hydraulic overload protected pump is used to protect the press and the die from overloading.

7. The motorized slide adjusting device is adopted with a thin brake motor and operated with push buttons. It offers stable positioning accuracy and quick adjustment.

3. The wet cultch produced by World is made up of the best seals, bearing and friction discs. It features lower noise and longer service life.

4. The control panel includes double hand buttons and emergency stop button and foot pedal control switch is optional.

5. The press is equipped with auto lubrication pump and it is easy for maintenance.

6. The hydraulic overload protected pump is used to protect the press and the die from overloading.

7. The motorized slide adjusting device is adopted with a thin brake motor and operated with push buttons. It offers stable positioning accuracy and quick adjustment.

Hot Searches