- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

95%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Wanyi

-

Voltage:

-

380V,50HZ

-

Dimension(L*W*H):

-

1250x450x700

-

Weight:

-

400 KG

-

Name:

-

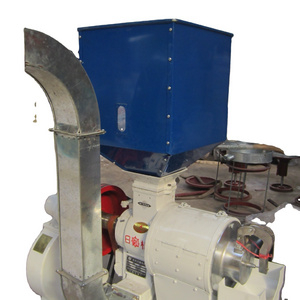

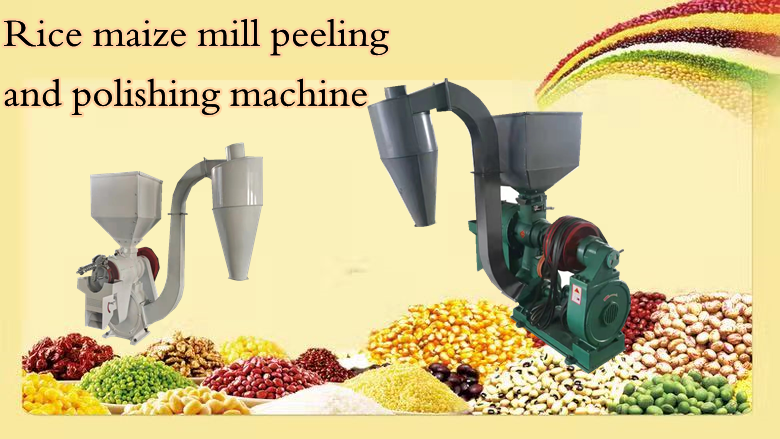

maize peeling and polishing machine corn peeling thresher machine

-

Function:

-

grain peeler

-

Keyword:

-

grain wheat maize peeling machine

-

speed of main shaft:

-

800~900t/m

-

Capacity:

-

500-2500kg/h

-

Color:

-

Customized Color

-

Package:

-

Wooden Case Packing

-

Crops:

-

Millet, sorghum, corn, wheat, barley, mung beans, soybeans etc

-

Power:

-

7.5-22kw

Quick Details

-

Marketing Type:

-

New Product 2023

-

Type:

-

Electric

-

Use:

-

grain seed peeling machine

-

Production Capacity:

-

95%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Wanyi

-

Voltage:

-

380V,50HZ

-

Dimension(L*W*H):

-

1250x450x700

-

Weight:

-

400 KG

-

Name:

-

maize peeling and polishing machine corn peeling thresher machine

-

Function:

-

grain peeler

-

Keyword:

-

grain wheat maize peeling machine

-

speed of main shaft:

-

800~900t/m

-

Capacity:

-

500-2500kg/h

-

Color:

-

Customized Color

-

Package:

-

Wooden Case Packing

-

Crops:

-

Millet, sorghum, corn, wheat, barley, mung beans, soybeans etc

-

Power:

-

7.5-22kw

|

MODEL

|

NX80

|

NX110

|

NX160

|

NX200

|

|

OUTPUT(KG/H)

|

500-800

|

1000-1500

|

1500-2000

|

2000-2500

|

|

POWER(KW)

|

7.5-11

|

11-15

|

15-18.5

|

18.5-20.5

|

|

SPEED OF MAIN SHAFT

|

800-900

|

750-850

|

750-850

|

950-1000

|

|

SPEED OF BLOWER(R/M)

|

3500

|

3500

|

3500

|

3500

|

|

MOTOR PULLEY(MM)

|

157

|

165

|

190

|

220

|

The working principle :

The material mouth

The fan impeller

Product features:

2. Rice, wheat, sorghum and rice can peel and polish at the same time.

3. Efficient winnowing and dust removal blower is installed inside the product.

4. High output and good effect.

The outlet of the peeling chamber can precisely control the residence time of sorghum or wheat in the peeling chamber through the pressure valve, and ensure the effective friction with the alloy roller, so as to achieve better peeling effect.

LuoHe WanYi Grain Machinery Co.,Ltd is a professional manufacturer of all types of flour equipment ,as many kinds of seeds wheat/maize/corn/rice /bean,etc. and We are a manufacturer with more than 20 years of production experience, and have professional high-quality engineers and good after-sales service, our products are exported to all parts of the world, and get consistent praise from customers at home and abroad! Company successively more than hundred food processing enterprise at home and abroad to establish a long-term stable cooperation relations, production technology with the good faith management and excellent product quality by the user's high praise, and exported to Russia, Canada, America, Africa and the Middle East market and other regions, and with "high quality, high technology content, good quality of service", and many other advantages, was rated "excellent supplier" and so on many enterprise users.The company will give full play to its innovation advantages, location advantages resource advantages, uphold the core values of"credit, responsibility, technology, quality", constantly create better social and economic benefits, and promote the company to achieve new leaps forward.

Our production capacity is from 5 ton to 500 ton per day. We provide turnkey project of our machinery, including special design, installation instruction, commissioning and training workers.

→We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q2:The payment?

→our company accept L/C,TT;

Q3:About he delivery time ?

→Generally speaking, the products will be delivered within ten to thirty days;

Q4:The quality of our products?

→Welcome our company to inspect the goods, we will also provide customers with video materials and product pictures;

Q5:Equipment warrant?

→Two year.