We have the professional engineer teams and sales teams, and we have technology and experiences in engineering plastic industry for more than 15 years! Our company is located in Huangpu District, Guangzhou City, China, where the logistics is developed! With the rich experiences and technology for manufacture, design,research and development ability, support personalized customization. We have full set of high efficiency producing equipment and advanced numerical control machines,such as: molding injection machines, CNC molding manufacture machines, fine carving machines,Horizontal lathes, milling machines. We can customize all kinds of Engineering plastics products according to our customers’drawings or samples.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

M-2498, 001

-

Material:

-

ABS

-

Product name:

-

Plastic Injection Molding

-

Plastic Modling Type:

-

Injection Blow Molding

-

Color:

-

Custom Color

-

Processing Service:

-

Special Size

-

Drawing Format:

-

IGS

-

Size:

-

Customized Size

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Guangdong, China, Guangdong

-

Brand Name:

-

gz-plastic, OEM Brand

-

Model Number:

-

M-2498, 001

-

Material:

-

ABS

-

Product name:

-

Plastic Injection Molding

-

Plastic Modling Type:

-

Injection Blow Molding

-

Color:

-

Custom Color

-

Processing Service:

-

Special Size

-

Drawing Format:

-

IGS

-

Size:

-

Customized Size

Guangdong Engineering Plastics Industries (Group) Co. Ltd.

Product Display

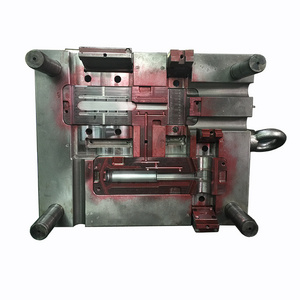

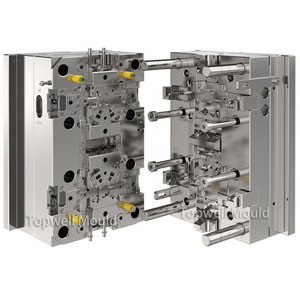

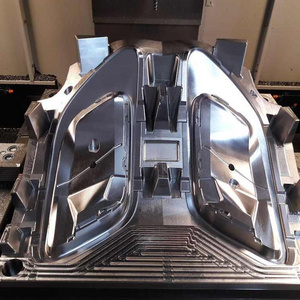

1.Plastic Injection Mold Making

Molds are constructed through two main methods:

standard machining and electrical discharge machining(EDM).

|

name

|

professional high precision plastic injection parts

|

|

|

|

|||

|

color

|

white,black,green,nature,blue,yellow,etc

|

|

|

|

|||

|

material

|

ABS,PMMA,PC,PP,PEEK,PU,PA,PA+GF,POM,PE,UPE,PTFE,etc

|

|

|

|

|||

|

mould cavity

|

single cavity & multi cavity

|

|

|

|

|||

|

runner system

|

hot runner and cold runner

|

|

|

|

|||

|

equipment

|

CNC, EDM, cutting off machine,plastic machinery etc

|

|

|

|

|||

|

mould material

|

P20/ 718H/ S136H/ S136 hardened/ NAK80

|

|

|

|

|||

|

injection machine

|

88T, 90T, 120T, 168T, 200T, 380T,420T,1200T

|

|

|

|

|||

|

mould life

|

500000-5000000 shots as per customers' requirement

|

|

|

|

|||

|

size

|

5-1000mm,or customized

|

|

|

|

|||

|

tolerance

|

± 0.01mm

|

|

|

|

|||

|

shape

|

as per your drawing or the sample

|

|

|

|

|||

|

certification

|

ISO9001 and relate whole set professional test report

|

|

|

|

|||

|

free sample

|

available

|

|

|

|

|||

|

advantage

|

one stop procurement

|

|

|

|

|||

|

Application field

|

Various plastic injection molded parts for various industrial and automotive applications

|

|

|

|

|||

|

lead time

|

15-30 days for mould,plastic products according to quantity

|

|

|

|

|||

|

other

|

24 hours instant and comfortable customer service

|

|

|

|

|||

|

|

shipping status notification during delivery

|

|

|

|

|||

|

|

regular notification of new styles & hot selling styles

|

|

|

|

|||

2.Plastic Injection Molding Products

We can customize all kinds of Engineering plastics products according to customers’drawings or samples.

3. 500+ Material Choices Custom Injection Molding

Guangdong Engineering plastics company strive to be leaders in the custom plastics industry. That’s why we’re proud to offer a wide variety of Engineering materials that we use to manufacture our custom plastic products. Below is the list of materials that we offer for thermoforming and injection molding products for our customers.Nylon6, Nylon66, PA6,

PA66,PA6+GF,ABS,ABS+GF,ABS+PC,POM(Derlin),PP,PE,PC,PVC,PMMA(Acrylic),TRU,EPDM,NBR,Silicon,UHMWPE,PVDF,PTFE,ETFE,PFA,PCTFE,FEP,PVF,PSF, PEI, PSU,PPSU, PPS, PEEK, PAI, PI, PBI,etc.

PA66,PA6+GF,ABS,ABS+GF,ABS+PC,POM(Derlin),PP,PE,PC,PVC,PMMA(Acrylic),TRU,EPDM,NBR,Silicon,UHMWPE,PVDF,PTFE,ETFE,PFA,PCTFE,FEP,PVF,PSF, PEI, PSU,PPSU, PPS, PEEK, PAI, PI, PBI,etc.

Customization

We have a professional engineer team to design custom parts for your needs , we also have ready-made standard moulds that can save your cost and time . We offer ODM/OEM service, Production Design and Mould Design base on your requirement . Providing the sample before mass production , ensure all is OK for you .

If you have any problems or want to get the quoted price of any plastics or machined components, please feel free to contact us. Our engineers will reply to you as soon as possible.

Our Factory

The factory covers an area of 10,000 square meters Production equipment has the original American imported Haas CNC machining center, wire-electrode cutting, electrical discharge machine,Perforating machine, injection molding machine, CNC milling machine,CNC hobbing machine, CNC lathe, CNC milling machine, CNC lathe, CNC milling machine, grinding machine and other machinery and equipment.

Our company is developing in the mode of quality for survival, brand for development and customer's demand, welcome new and old customers to visit our factory for guidance.

Q1. Can only samples be produced?

A1. Yes.

Q2. What is the accuracy of the products processed by the drawings?

A2. Different equipment has different accuracy, generally between 0.05-0.1

Q3. What craftsmanship do you have for processing accessories?

A3.According to different products, different processes are used, such as machining, extrusion, injection molding, etc.

Q4. What areyour processing equipment?

A4. CNC machining center, CNC lathe, milling machine, engraving machine, injection molding machine,extruder, molding machine.

Q5. Can you help assembling the product after it is made?

A5. It's okay

Q6. What certifications or qualifications does your company have?

A6. Our company’s certificates are: ISO, ROHS, product patent certificates, etc.

Q7. Can injection products be surface treated? What are the surface treatments?

A7. It is ok. Surface treatment: spray paint, silk screen,electroplating, etc.

Hot Searches