- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HAOLU

-

Voltage:

-

3kw or depends on model

-

Dimension(L*W*H):

-

various

-

Weight:

-

3500 KG

-

Product name:

-

High quality rotary drum screen machine

-

Machine type:

-

Trommel Screening Machine

-

Keyword:

-

Vibratory Screen

-

Function:

-

Screening\separation\sorting\sieving

-

Advantage:

-

Easy To Operate

-

Usage:

-

Sand Screening

-

Applicable Material:

-

Compost,topsoil,gravel,sand

-

Customized:

-

Support

-

Screen Mesh:

-

3-10mm

-

Raw material:

-

Stainless Steel

Quick Details

-

Type:

-

Trommel Screen

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HAOLU

-

Voltage:

-

3kw or depends on model

-

Dimension(L*W*H):

-

various

-

Weight:

-

3500 KG

-

Product name:

-

High quality rotary drum screen machine

-

Machine type:

-

Trommel Screening Machine

-

Keyword:

-

Vibratory Screen

-

Function:

-

Screening\separation\sorting\sieving

-

Advantage:

-

Easy To Operate

-

Usage:

-

Sand Screening

-

Applicable Material:

-

Compost,topsoil,gravel,sand

-

Customized:

-

Support

-

Screen Mesh:

-

3-10mm

-

Raw material:

-

Stainless Steel

NO.1 Product Description

Drum screening machine is a traditional screening equipment. After the broken stone enters the drum, the material is screened by the centrifugal force and jig of the drum rotation. Sifting through different mesh screens one by one. The stone material of different specifications is screened out and dropped into the belt conveyor through the funnel and sent to the finished material yard. The utility model has the advantages of simple and reliable structure, stable operation, good sealing, no pollution, low noise, fast network change, fine classification, large separation ratio, high output, fast separation, low failure rate, convenient maintenance, etc., Especially suitable for the classification of sand and stone field. Sand screening machine, also known as dry sand screening ship, is suitable for river, reservoir, coal yard sand and stone separation equipment. It consists of a hull, shelf, reducer, conveyor belt, rotating screen, engine or motor. This machine has the advantages of simple structure, economical application and easy operation. It is divided into drum type sand screen, washing drum type sand screen, vibrating screen type sand screen, etc.

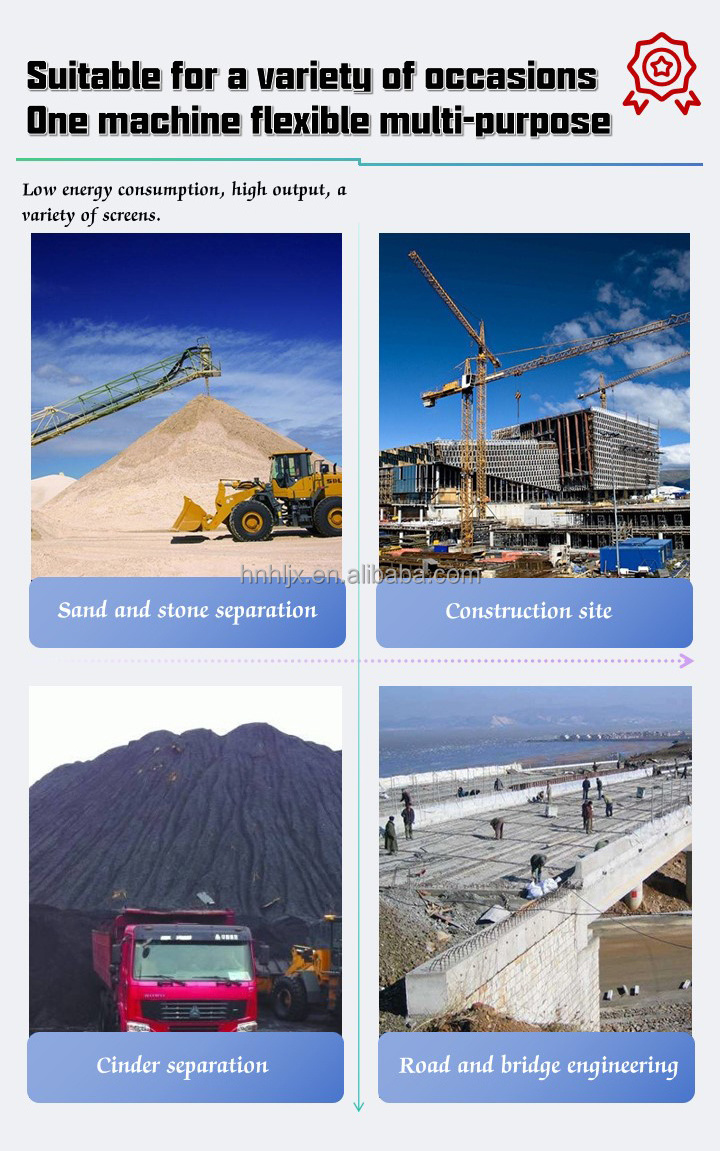

NO.2 Product Application

The roller screen is mainly for grading the particle size of the material, and is widely used in power, mining, metallurgy, building materials, chemical industry and other production industries. It is often used for the classification of refractory materials, coal, sand stones, as well as the screening of sticky and wet materials such as coal, coke, white ash, sand and gold ore, so that the product structure is more uniform to meet the production needs.

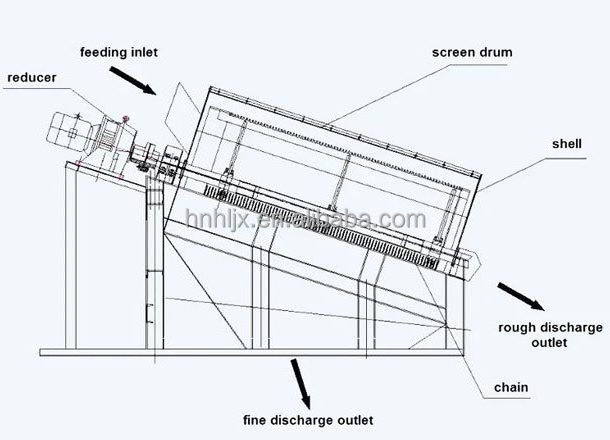

NO.3 Working Principle

1, The whole equipment of the cylindrical river sand screening machine is composed of raw material storage hopper, raw material feeding belt conveyor, flat screen mesh, finished sand pile material belt, and abandon stone discharge trough.

2, After the equipment is energized, the loader will load the raw materials.

3, Into the large-capacity storage hopper, the raw material is put into the flat sieve cylinder through the feeding belt, and the rotating sieve cylinder drives the raw material to form the artificial sieve effect of the raw material sliding on the screen surface.

4, Under the pushing and tumbling of the inner blade of the cylinder, the finished sand falls on the finished sand belt through the collecting hopper, and is lifted down by the belt into a finished material pile or directly into the storage hopper.

5, The whole process is continuous and the material classification is clear and accurate.

NO.4 Main Technical Parameters

|

Model

|

Capacity

|

Power

|

Diameter

|

Length

|

Screen size

|

Dimension

|

Weight

|

|

LZGT0610

|

5-10t/h

|

2.2kw

|

600mm

|

1000mm

|

1-50mm(can use double and three layers)

|

2520/1020/1860mm

|

1600kg

|

|

LZGT0815

|

8-18t/h

|

3kw

|

800mm

|

1500mm

|

|

2860/1300/2060mm

|

1800kg

|

|

LZGT1015

|

10-20t/h

|

4.0kw

|

1000mm

|

1500mm

|

|

3060/1400/2145mm

|

2200kg

|

|

LZGT1020

|

20-25t/h

|

5.5kw

|

1000mm

|

2000mm

|

|

3460/1400/2145mm

|

2800kg

|

|

LZGT1225

|

25-35t/h

|

7.5kw

|

1200mm

|

2500mm

|

|

4146/1600/2680mm

|

4200kg

|

|

LZGT1530

|

35-50t/h

|

11kw

|

1500mm

|

3000mm

|

|

4460/1900/2820mm

|

5100kg

|

|

LZGT1545

|

50-70t/h

|

15kw

|

1500mm

|

4500mm

|

|

5960/1900/3080mm

|

6000kg

|

|

LZGT1848

|

70-90t/h

|

22kw

|

1800mm

|

4800mm

|

|

6500/2300/4000mm

|

7500kg

|

|

LZGT2055

|

90-120t/h

|

30kw

|

2000mm

|

5500mm

|

|

7500/2500/4000mm

|

8600kg

|

Note:

The technical parameters of some commonly used models are shown in the details, and the length and number of screen segments can be customized according to requirements.

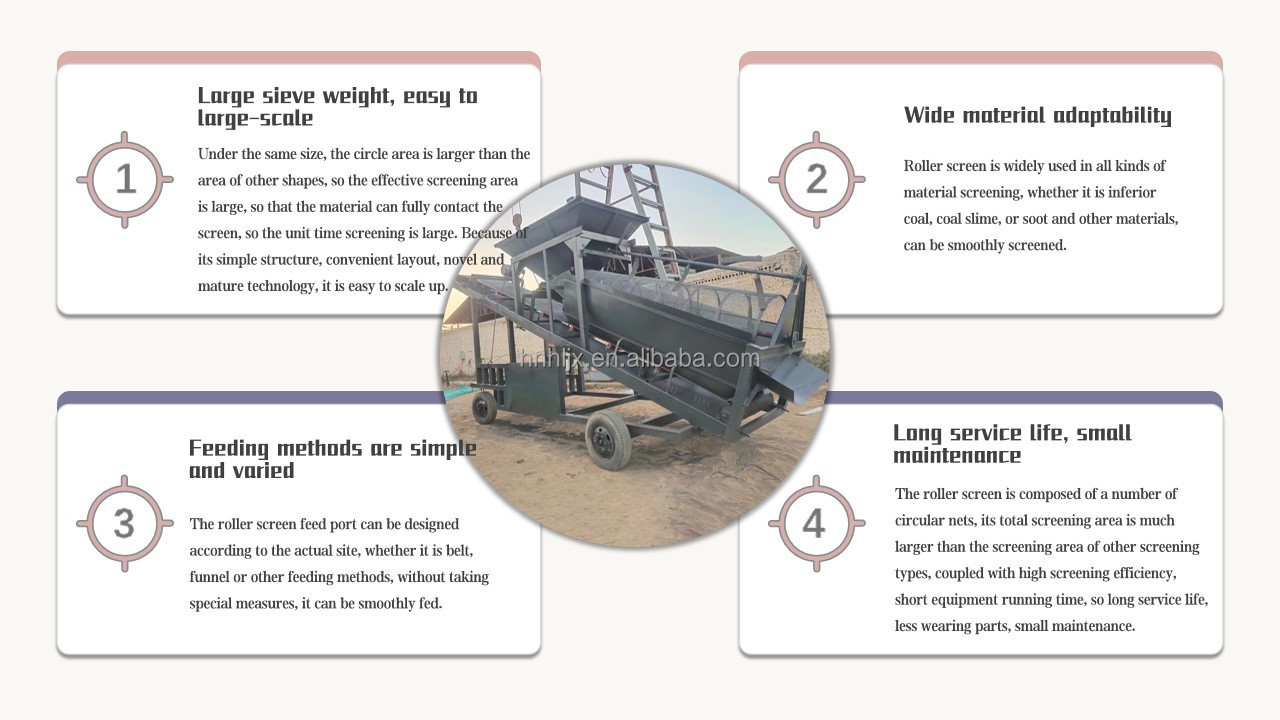

NO.5 Main Features

1, Wide material adaptability

It is used for screening of various materials. No matter it is inferior coal, slime, soot or other materials, it can be screened smoothly.

2, High screening efficiency

The equipment can be equipped with comb cleaning mechanism. In the screening process, the materials entering the screening cylinder can be screened according to impurities and dirt to improve the screening efficiency of the equipment.

3, The screening composition is large and easy to enlarge

In the same size, the circular area is larger than other shapes, so the effective screening area is large, so that the material can fully contact the screening, so that the screening component per unit time is large.

4, Good working environment

The whole screening cylinder can be sealed with a sealed isolation cover to completely eliminate dust and block splashing during screening and avoid pollution to the working environment.

Hot Searches