- Product Details

- {{item.text}}

Quick Details

-

No. of Slitting Lines:

-

5 - 12

-

Coil Weight (T):

-

20 T

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

TT

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

19*10*4

-

Weight:

-

10

-

After-sales Service normally:

-

installation, commissioning and training

-

Online service:

-

Online support

-

Technical service:

-

Video technical support

-

Engineer:

-

Engineers available to service machinery overseas

-

Nominal power::

-

250kw

-

Rated DC power:

-

Pd=295kW

-

Rated DC voltage:

-

UdN=450V

-

Rated DC current:

-

IdN=650A

-

keyword:

-

Seam Welder

-

Certification:

-

ISO9001

Quick Details

-

Cutting Width (mm):

-

600 - 1500 mm

-

Material Thickness(mm):

-

0.5 - 3 mm

-

Cutting Speed(m/min):

-

50 - 100 mm

-

No. of Slitting Lines:

-

5 - 12

-

Coil Weight (T):

-

20 T

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

TT

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

19*10*4

-

Weight:

-

10

-

After-sales Service normally:

-

installation, commissioning and training

-

Online service:

-

Online support

-

Technical service:

-

Video technical support

-

Engineer:

-

Engineers available to service machinery overseas

-

Nominal power::

-

250kw

-

Rated DC power:

-

Pd=295kW

-

Rated DC voltage:

-

UdN=450V

-

Rated DC current:

-

IdN=650A

-

keyword:

-

Seam Welder

-

Certification:

-

ISO9001

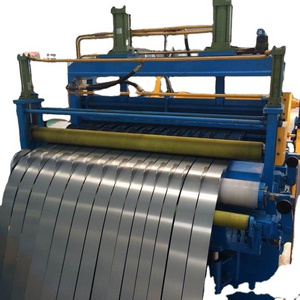

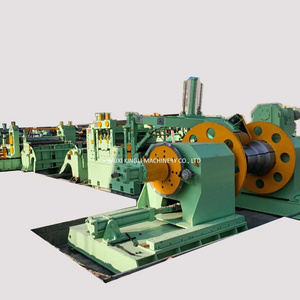

used steel coil slitting line machine from germany

Slitting line machine mainly composed of uncoiler,feeder,slitter and recoiler.its function is to slit a wide coil to stated width strips coil along with the length direction which can be used for milling,welding pipe,cold bend forming,stamping as billet. At same time,changing different material blade can slit various metal coils.

Main technical parameter:

| Material of coils | HR/CR carbon steel such as Q235, galvanized plate, colored steel plate etc |

| Metal Coil Slitter Strip thickness | (0.4-4) mm |

| Strip width | 800~2000mm |

| Max.coil weight | 40000kgs |

| Diameter of leveling rollers & tensioning roller | Φ260 |

| Metal Coil Slitter Diameter of slitter shaft | Φ420 |

| Coil Slitting Machine Disc cutters | 6CrW2Si, HRC54°~56°, OD650mm x ID420mm x T50mm |

| Diameter of recoiler block | Φ800mm |

| Separating discs | 65Mn, OD250 x ID110 x T10/20mm |

| DC motors for slitter and recoiler | 280KW, 315KW |

| Coil Slitting Machine Slitting speed | (50-100) m/min, adjustable |

Product Process:

Loading coil car→Uncoiler→Straightener device→Pinch roll&leveler & hydraulic shearer →Loop pit →Side guide →Slitter →Transition platform & scrap winder →Loop pit →Tension station→Recoiler→Unloading coil car.

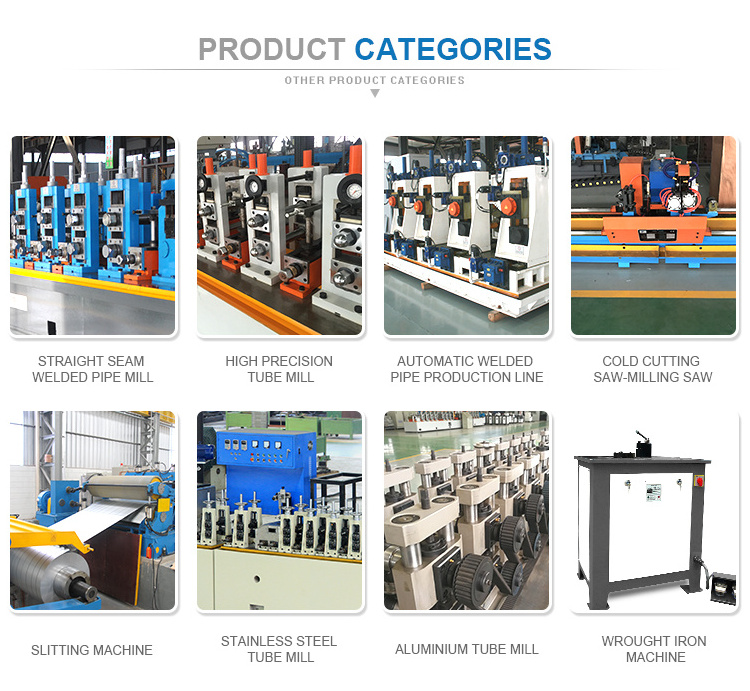

Model Of Slitting Line:

|

Model |

Plate thickness |

Plate width |

Steel coil weight |

Width of finished |

Shear Speed |

|

3*1250mm |

0.5-3.0mm |

700-1250mm | 25 T on |

<40mm |

120(m/min) |

|

4*1250mm |

0.5-4.0mm | 700-1250mm | 25 T on | <40mm | 120(m/min) |

| 6*1250mm | 0.5-6.0mm | 700-1250mm | 25 T on | <40mm | 120(m/min) |

|

3*1600mm |

0.5-3.0mm |

900-1600mm |

30 Ton |

≥40mm |

120(m/min) |

|

4*1600mm |

0.5-4.0mm |

900-1600mm |

30 Ton |

≥60mm |

110(m/min) |

|

6*1600mm |

1-6mm |

900-1600mm |

30 Ton |

≥60mm |

100(m/min) |

|

8*2000mm |

2-8mm |

900-2000mm |

35 Ton |

≥70mm |

60(m/min) |

|

10*2200mm |

3-10mm |

900-2200mm |

35 Ton |

≥80mm |

50(m/min) |

|

12*2200mm |

3-12mm |

900-2200mm |

35 Ton |

≥100mm

|

40(m/min) |

|

16*2500mm |

4-16mm |

900-2500mm |

35 Ton |

≥100mm

|

40(m/min) |

|

20*2500mm |

6-20mm |

900-2500mm |

35 Ton |

≥100mm

|

30(m/min) |

This model just for you reference,the product range and thickness is adjustable,we have ourselves engineer team,can design the machine according to the customer special require.

Send inquiry here

1.) We will send the engineer for the installation and training your workers how to operate this machine in correct way.

2.) Warranty Team

One year quality guarantee, life guarantee repair. Within quality guarantee period, except for failures caused by human error, repair parts will be provided for free. After the quality guarantee period, only charge the cost of the spare parts.

3.) We supply the pre-sell and after-sell service.

pre-sell service: workshop design, and production output design

after-sell service: installation and training, and the skilled engineer for working.

4.) We can also sent the engineer working for you serval months or 1 year. The engineer will help you to improve the output, reduce the waste and decrease the cost.

5.) We supply the pre-sell service-Design for whole project for stainless steel pipe making/ carbon steel pipe making.

6.) We will be responsible for the loading and shipping.