- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

EVERGAIN

-

Model Number:

-

Ceramic tiles sealer

-

Type:

-

Two Component

-

Product name:

-

Ceramic Tile Waterproof Sealer

-

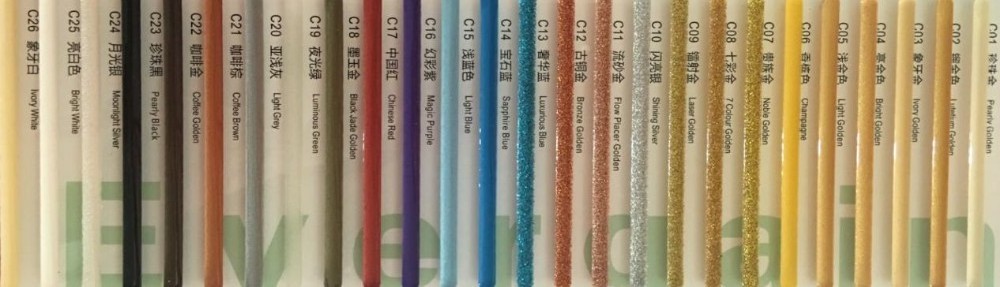

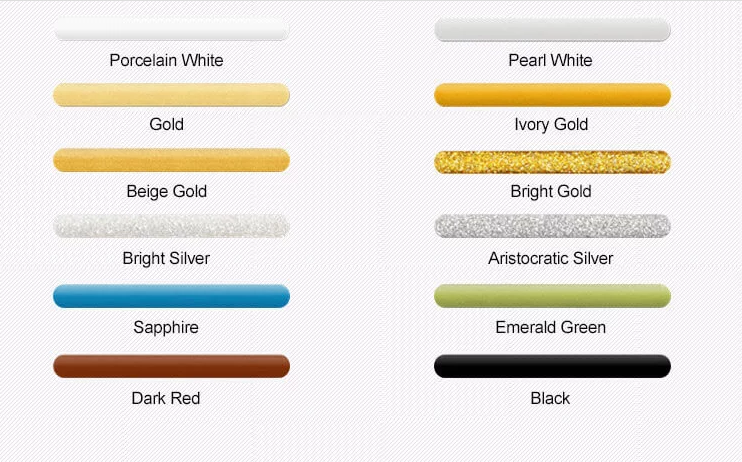

Color:

-

Gold,White,Silver,Black,Green,Red,yellow,etc

-

Surface dry time:

-

2hours

-

Shelf life:

-

18 Months

-

Full dry time:

-

8-12hours

-

Packing:

-

400ml/set

-

Temperature:

-

-60℃ to 100℃

-

Features:

-

anti-mildew,wear-resistant,etc

-

Cutting length:

-

70-80MPa

-

Application:

-

ceramic,glass,wood,etc.

Quick Details

-

CAS No.:

-

7085-85-0

-

Other Names:

-

Waterproof Sealer

-

MF:

-

Mixture

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

EVERGAIN

-

Model Number:

-

Ceramic tiles sealer

-

Type:

-

Two Component

-

Product name:

-

Ceramic Tile Waterproof Sealer

-

Color:

-

Gold,White,Silver,Black,Green,Red,yellow,etc

-

Surface dry time:

-

2hours

-

Shelf life:

-

18 Months

-

Full dry time:

-

8-12hours

-

Packing:

-

400ml/set

-

Temperature:

-

-60℃ to 100℃

-

Features:

-

anti-mildew,wear-resistant,etc

-

Cutting length:

-

70-80MPa

-

Application:

-

ceramic,glass,wood,etc.

Ceramic Tile Sealer is a double-component epoxy adhesive for ceramic tile gap filling, mainly use epoxy resin, curing agent and high-grade pigment as raw material, adopt advanced technology. It is better than water-based tiler sealer in application way and effect, it is smooth as ceramic after cured, good hardness,wear-resistant, stain-resistant, and easy to clean.

Rich and bright color can meet all decoration needs.

1. All kinds of cabinets aperture, window, furniture, etc

2. All kinds of edges of Kitchen, toilet, also can be used to paste all kinds of hard materials

3. Bathtub, shower room, glass partition, implement, lavabo, mesa and basins of guesthouse

4. Hotel, family, such as the installation of sanitary ware, waterproof, plugging and decoration processing.

1. Preparation

Tile decoration grout, injection dispenser, texture paper, knife, gap cleaning awl, edge pressing ball, water scraper, materials scraper, etc.

2. Processing

(1) Cleaning the tile gap and stick the texture paper

Keep about 3mm groove and 2mm width pf the tile gap, with the paper on both sides, must keep the crossing area clean, stick the texture paper close to the gap;

(2) Put the cartridge into the dispenser

Press the button to pull the rod out and open the cartridge to keep the opening upside, screw the mixer to the opening, then put the cartridge into the dispenser. The opening of the mixer can be adjusted by cutting to fit the gap sizes. (smaller than the gap.)

(3) Start to process

At the beginning, need to remove the first mixed grout, about 40cm, for a new hand, suggest to inject 20-50cm for practice, then increase the length accordingly. Smoothen the grout by using water scraper, edge pressing ball and even finger. If still any grout remain inside the dispenser, lay it flat-wise. Need a materials scraper to hold under the opening of the mixer. If find any uneven place, keep injection. After all gaps of the paper smoothened, remove the paper and keep in stand for 24 hours.

Attention

1.Remove the first mixed grout about 40cm

2.Keep the grout in the mixer opening no longer than 20 minutes, to avoid hard to squeeze the grout, so make sufficient preparation in advance.

3.Gap width above 1.5mm, to make sure the under gap flat without dirts.

4.The grout can be completely hardened after 12 hours, but can be longer if the temperature is low, so it is normal if slow in winter.

5.If the grout can not be used in one time, remember to clean the grout in the mixer opening, and recap to keep in cool place for 12 months, replace a new opening when reuse.