Tinwing can provide a key solution according to customer requirement . We have professional R&D Engineers, manufacturing

engineers, electrical engineers as well as service team. When you purchase a Tinwing product, will receive a key solution service

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Tinwing, Tinwing

-

Dimension(L*W*H):

-

Customized

-

Capacity:

-

Customized

-

Weight:

-

1000

-

Inner Material:

-

Q345R

-

Outer Material:

-

Q345R

-

Design Pressure(MPa):

-

customized

-

Design Standard:

-

ASME/PED/GB

-

Working Temperature(℃):

-

100 - 500 ℃

-

Product name:

-

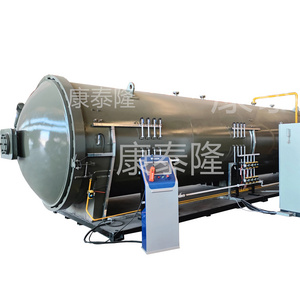

high temperature autoclave

-

Door seal type:

-

Inflatable silicone seal ring

-

Control System:

-

Automatic Control

-

Advantage:

-

High Efficiency

-

Working pressure:

-

Customer's need

-

After-sales Service Provided:

-

High Pressure Composite Carbon Fiber Curing Autoclave for industry

-

Use for:

-

space vehicle/ carbon fiber/glass fiber

-

Color:

-

Customized

Quick Details

-

Volume (m³):

-

10

-

Max Working Pressure(MPa):

-

customized

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tinwing, Tinwing

-

Dimension(L*W*H):

-

Customized

-

Capacity:

-

Customized

-

Weight:

-

1000

-

Inner Material:

-

Q345R

-

Outer Material:

-

Q345R

-

Design Pressure(MPa):

-

customized

-

Design Standard:

-

ASME/PED/GB

-

Working Temperature(℃):

-

100 - 500 ℃

-

Product name:

-

high temperature autoclave

-

Door seal type:

-

Inflatable silicone seal ring

-

Control System:

-

Automatic Control

-

Advantage:

-

High Efficiency

-

Working pressure:

-

Customer's need

-

After-sales Service Provided:

-

High Pressure Composite Carbon Fiber Curing Autoclave for industry

-

Use for:

-

space vehicle/ carbon fiber/glass fiber

-

Color:

-

Customized

Product Description

ASME fully automatic vacuum line high temperature and pressure composite carbon fiber autoclave

Product Introduction:

The composite material autoclave mainly used to the composite materials by high temperature and high pressure, such as space vehicle.It also can be applied to strengthen the carbon fiber,glass fiber etc.

Product Composition:

Autoclave is composed of ten system parts, including tank , door sealing device, heating system, pressure system, cooling system, vacuum system, air source system, safety system,automatic control system and auxiliary supporting system composition:

System Composition:

Tank:

The tank consists of tank body, door, high-temperature motor, insulating layer and so on, All these form a tank which can resistance high pressure and high temperature.

The tank consists of tank body, door, high-temperature motor, insulating layer and so on, All these form a tank which can resistance high pressure and high temperature.

Heating system:

Use high quality stainless steel heating tube as heating source.High heating efficiency, service life long.

Use high quality stainless steel heating tube as heating source.High heating efficiency, service life long.

Temperature cycling system:

Select high quality circulating fan, a wind guiding plate and a diversion cover form a uniform temperature field.Ensure even hot air circulation and temperature.

Select high quality circulating fan, a wind guiding plate and a diversion cover form a uniform temperature field.Ensure even hot air circulation and temperature.

Pressure system:

It includes a compressor, a gas storage tank, pressure control valves, pipeline, pressure sensor, pressure gauge and so on.

It includes a compressor, a gas storage tank, pressure control valves, pipeline, pressure sensor, pressure gauge and so on.

Door sealing device:

Adopted silicone inflatable gasket, can resist high temperature 400 ℃.

Cooling system:

The cooling system consists of stainless steel cooler, precooling Angle seat valve, pipe filter, circulating water tank,circulating water pump, cooling tower, etc

Vacuum system:

It includes of vacuum pump, pipeline, vacuum gauge and vacuum valve.

Safety interlock device:

Safety interlock device include high pressure automatic interlocking, manual interlocking, and ultra-high pressure alarm device.

Automatic control system:

Adopting SIEMENS PLC control system realizes high precision control of the pressure, temperature, cooling and other process parameters and real-time recording.

Adopted silicone inflatable gasket, can resist high temperature 400 ℃.

Cooling system:

The cooling system consists of stainless steel cooler, precooling Angle seat valve, pipe filter, circulating water tank,circulating water pump, cooling tower, etc

Vacuum system:

It includes of vacuum pump, pipeline, vacuum gauge and vacuum valve.

Safety interlock device:

Safety interlock device include high pressure automatic interlocking, manual interlocking, and ultra-high pressure alarm device.

Automatic control system:

Adopting SIEMENS PLC control system realizes high precision control of the pressure, temperature, cooling and other process parameters and real-time recording.

Product Superiority

2.Good measurement accuracy,

3.Stable running,

4.Low energy consumption,

5.Simple operation.

Size Information

|

TYPE

|

1600*2500

|

2000*3500

|

2500*5500

|

3000*6500

|

3500*7500

|

4000*8500

|

|

Max Work Pressure

|

3.8MPa

|

1.0MPa

|

1.0MPa

|

1.5MPa

|

1.2MPa

|

1.2MPa

|

|

Design Pressure

|

4.0MPa

|

1.2MPa

|

1.2MPa

|

1.6MPa

|

1.3MPa

|

1.3MPa

|

|

Maximum Working Temperature

|

400℃

|

250℃

|

250℃

|

250℃

|

250℃

|

250℃

|

|

Design Temperature

|

420℃

|

270℃

|

270℃

|

270℃

|

270℃

|

270℃

|

|

Insulation

|

Internal insulation, 200mm

|

Internal insulation, 150mm

|

Internal insulation, 150mm

|

Internal insulation, 150mm

|

Internal insulation, 150mm

|

Internal insulation, 100-150mm

|

|

Total Power

|

60kw

|

90kw

|

210kw

|

330kw

|

510kw

|

780kw

|

Application Fields

Aerospace Industry

Automobile Industry

The New Field Of Energy

Packing&Shipping

Company Introduction

Shandong Tinwing Machinery Manufacturing Co. Ltd. is a professional pressure vessel manufacturer . The company has pressure vessel manufacturing certificates: China government pressure vessel A2 certificate (No. TS2237G06-2024), ASME and CE (PED). Tinwing has advanced manufacturing and detection equipment, strong technical power, strict detection standard and quality assurance system. We cooperate with many colleges scientific research institutes, military enterprises at R&D and manufacturing. Our autoclave can be applied in aerospace,defense weapon, transportation, racing car, sailing boat, fan, rubber shoes, rubber hose, wood vacuum pressure treatment, wood dyeing etc, widely used in many fields. We can provide a reasonable solution for customers according to their requirements. And we also provide the product's design, manufacturing, installation, commissioning , maintenance for customers.

We have cooperated many customers in many countries, such as America, Mexico, Columbia, Venezuela, Peru, Ecuador, Australia, Russia, Vietnam, Sri Lanka, Tajikistan, Ukraine, Saudi Arabia, Poland, United Kingdom, Spain, Libya etc.

We have cooperated many customers in many countries, such as America, Mexico, Columbia, Venezuela, Peru, Ecuador, Australia, Russia, Vietnam, Sri Lanka, Tajikistan, Ukraine, Saudi Arabia, Poland, United Kingdom, Spain, Libya etc.

Our Workshop

Our Customers

Certifications

FAQ

1. What are the payment terms?

T/T,L/C and trade assurance are acceptable,T/T will be more appreciated,30% deposit before production,70% balance before shipment.

2.What is the delivery time?

At least 2 month after the deposit for most machines

3.How to pack the machine?

Standard packaging

4.How to install after the machines arriving destination?

Our engineer will go to customers site if you need,but need to pay installation fee according to the contract.

5.What's the capacity you can do?

We always produce any capacity depend on customers' requirement.

T/T,L/C and trade assurance are acceptable,T/T will be more appreciated,30% deposit before production,70% balance before shipment.

2.What is the delivery time?

At least 2 month after the deposit for most machines

3.How to pack the machine?

Standard packaging

4.How to install after the machines arriving destination?

Our engineer will go to customers site if you need,but need to pay installation fee according to the contract.

5.What's the capacity you can do?

We always produce any capacity depend on customers' requirement.

Contact

SHANDONG TINWING MACHINERY MANUFACTURING CO.,LTD

NAME: Sunny Yang

E-mail: sunny @tyjxchina.com

Tel: +8618866710030 whatsap/wechat: +86 15063618468

Add:Xiangzhou Industrial Park,Zhucheng City,Shandong Province

NAME: Sunny Yang

E-mail: sunny @tyjxchina.com

Tel: +8618866710030 whatsap/wechat: +86 15063618468

Add:Xiangzhou Industrial Park,Zhucheng City,Shandong Province

Hot Searches