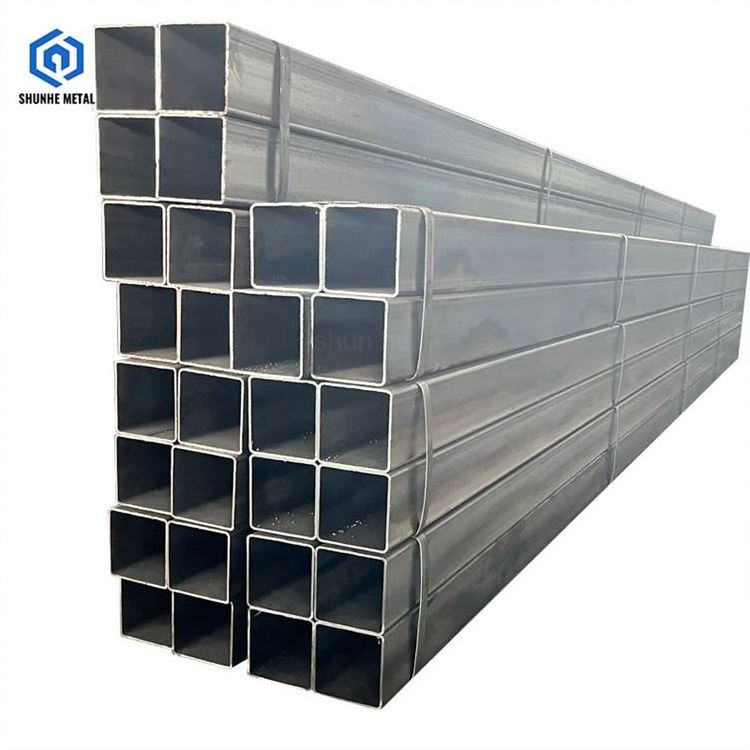

- Product Details

- {{item.text}}

Quick Details

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

shun he

-

Thickness:

-

1.0mm-12mm(or as buyer needs)

-

Grade:

-

carbon/ms/cs/mild

Quick Details

-

Section Shape:

-

rectangular

-

Surface Treatment:

-

Hot Rolled or cold rolled

-

Tolerance:

-

±5%, ±1%

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

shun he

-

Thickness:

-

1.0mm-12mm(or as buyer needs)

-

Grade:

-

carbon/ms/cs/mild

|

Welded pipe is an electric welded round pipe that is an alternative to steel pipes.It is a structural grade tube that is suitable for a wide variety of applications where dimensional accuracy and precision tolerances is not a primary concern.A raised weld seam is present inside the pipe.

|

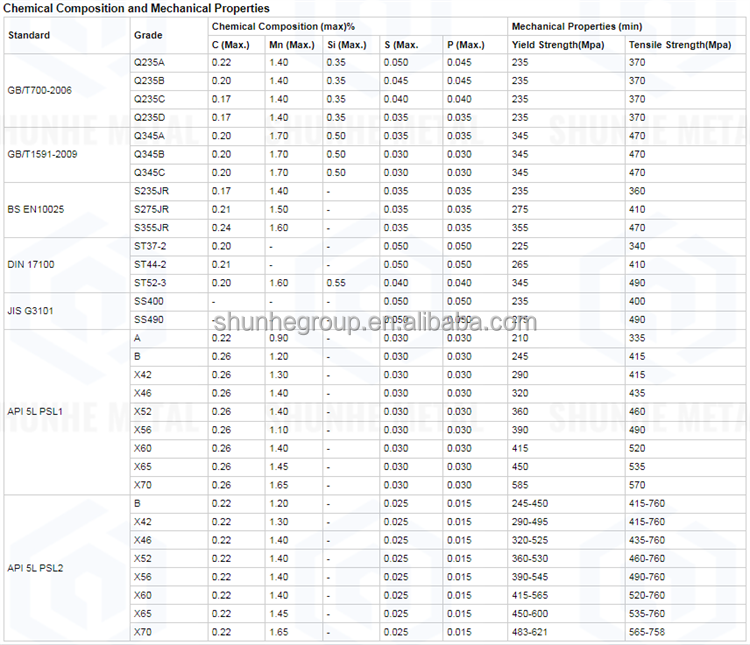

| Standards | API 5L ERW PSL1/PSL2, EN39, BS1139, BS1387, EN10255, |

|

ASTM A53, A500, A36, A795, ANSI C80, DIN2440, JIS G3444, GB/T3091, GB/T13793 |

|

| Certificate | API 5L ERW PSL1/PSL2, API 5CT, CE, ISO |

| Material |

Q195, Q215, Q235, Q275, Q295, Q345, S275, S355, 08F, 08, 08AL, 08F, 10F, 10, HG5, DF08 SPHC, M8 |

| ASTM A53: Gr.A, Gr.B, Gr.C, Gr.D | |

| API 5L: Gr.A, Gr.B, X42, X46, X52, X56, X60, X65, X70 | |

|

GB/T9711: L175, L210, L245, L290, L320, L360, L290, L320, L360, L390, L415, L450, L485, L555 |

|

| ASTM A252: Gr.1 Gr.2 Gr.3 | |

| Type | Spiral, ERW (Electrical Resistance Weld), EFW (Electric Fusion Welding) |

| Outside Diameter | 6mm-2500mm |

|

(1/8 inch, 1/4 inch, 1/2 inch, 3/4 inch, 1inch, 1 1/4 inch, 1 1/2 inch, 2inch, 2 1/2 inch, 3inch, 3 1/2 inch, 4inch, 5 inch, 6inch, 8 inch, 10 inch, 12inch, 14inch, 16 inch, 18 inch, 20 inch, 22 inch, 24 inch, 26inch, 28 inch, 30 inch, 32 inch, 34 inch, 36 inch, 38 inch, 40 inch, 42 inch, 44 inch, 46 inch, 48 inch) |

|

| Thickness | 1mm~220mm |

| (SCH5 ,SCH10,SCH20,SCH30,STD,SCH40,SCH60,XS, | |

| SCH80,SCH100,SCH120,SCH140,SCH160, XXS) | |

| Length | 6m-12m,or as required |

| Outside Coating | Anti-rust oil, black painting. |

| Epoxy Coating according to AWWA C-210 | |

| Bitumen Coating according to DIN30672, BS534 | |

| Coal- Tar Enamel Coating according to AWWA C-203 | |

| 3 Layer polyethylene Coating according to DIN30670 | |

| 3 Layer Polypropylene Coating according to DIN30678 | |

| Inside Coating | Epoxy lining according to AWWA C-210 |

| Bitumen Lining according to DIN30673, BS534 | |

| Coal-Tar Enamel Lining according to AWWA C-203 | |

| Cement Mortar Lining according to AWWA C-205, BS534 | |

|

Testing and Inspection Reports |

EN 10204 3.1, Mill TC EN 10204 3.1, Third Party Inspection Reports, Visual Inspection Reports, Destructive Test Report, Non Destructive Test Reports, PMI Test Reports, Chemical and Mechanical Reports, NABL Approved Lab |

| Price Term | EX-Work, FOB, CFR, CIF |

| Package | Wooden box, bundled for export standard or as required |

| Payment Term | T/T, L/C, |

| Delivery Time | 25-45 days (based on quantity) after receiving advanced payment |

| Application | a) General service industries (petroleum, food, chemical, |

| paper, fertilizer, fabric, aviation and nuclear) | |

| b) Fluid, gas and oil transport | |

| c) Pressure and heat transmission | |

| d) Construction and ornament | |

| e) Boiler heat exchangers |

|

Carbon steel piping is a durable material made from carbon steel, a steel alloy with iron and carbon. Because of its strength and ability to withstand stress, it is used in a variety of heavy-duty industries like infrastructure, ships, distillers, and chemical fertilizer equipment. Some of the most common uses of carbon steel tubing are Building foundations, Transporting natural gases or oil, Boiler and condenser tubes, Transporting wastewater, Chemical Processing, High-pressure applications, Transporting sewage, Bollard construction, Shipbuilding, Shoring, Trash enclosures, Distillers, OEM applications etc |

|

Mild steel welded tube 2> The welded pipe production line needs at least 7 sets of equipment, such as planing machine, pre-bending machine, forming machine, hydraulic testing machine, pre-welding machine, internal welding machine, external welding machine. the line adopts computer PLC control and famous brand machine which greatly improve efficiency of production.

According to different welding technique, there are straight seam, spiral seam etc, the basic production process is : Raw material uncoiling - leveling - end shearing and welding - looper - forming - welding - internal and external weld bead removal - pre-correction - induction heat treatment - sizing and straightening - eddy current testing - cutting - hydraulic inspection - pickling - final inspection (strict control) - packaging - shipment.

|

|

1. How can customer get the current best offer of pipes within 1 hour?

2. Where is your company located? Can customer visit you?

3. How is your company product & service guaranteed?

*third-party inspection is no problem.

4. What is your product delivery time? it takes 7-10 days for stock, and it maybe spends 15-25 days for larger quantity or customized product. We suggest customer chat with our sales person for accurate date.

Please contact us at any time if you have other question. |