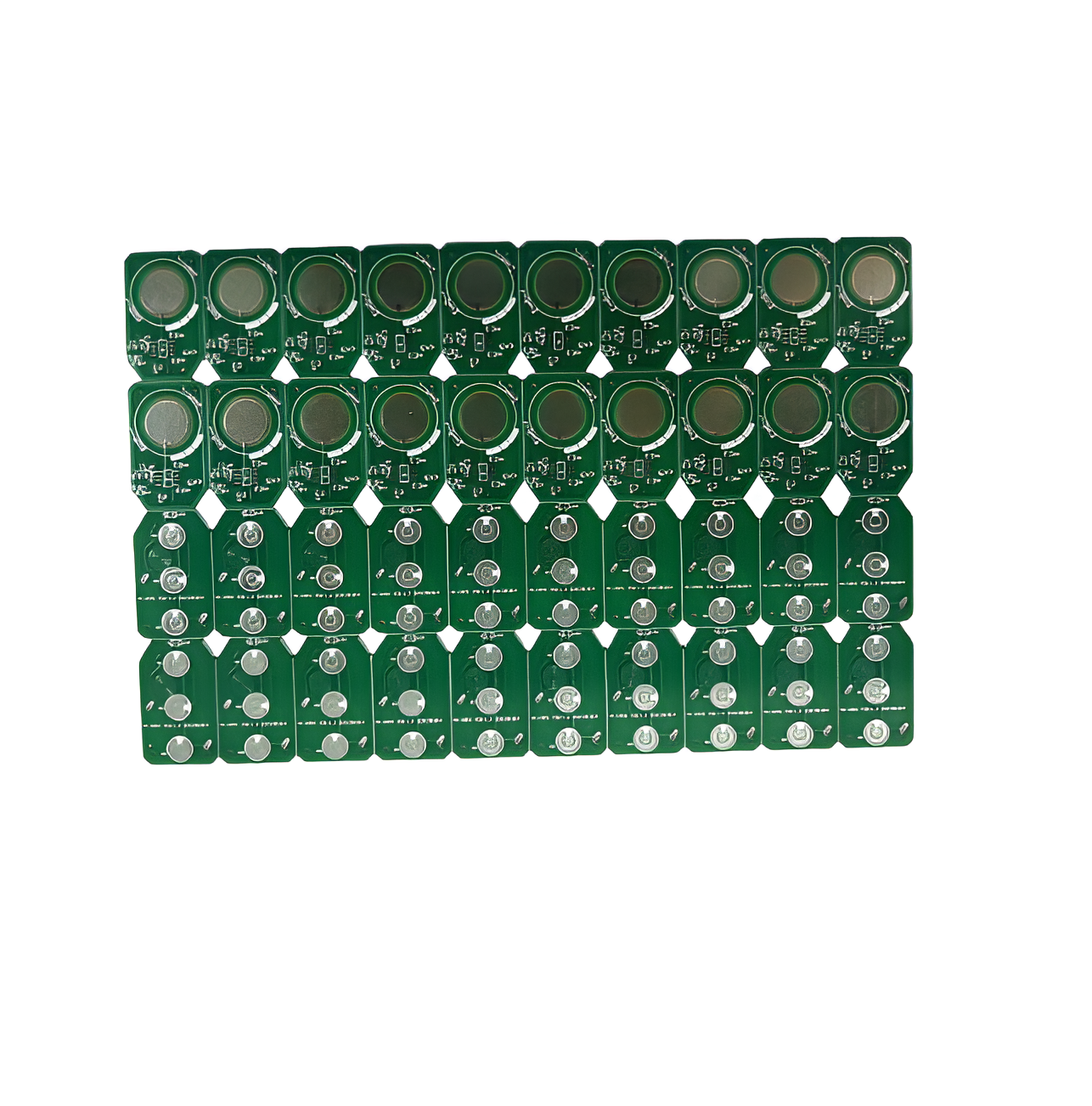

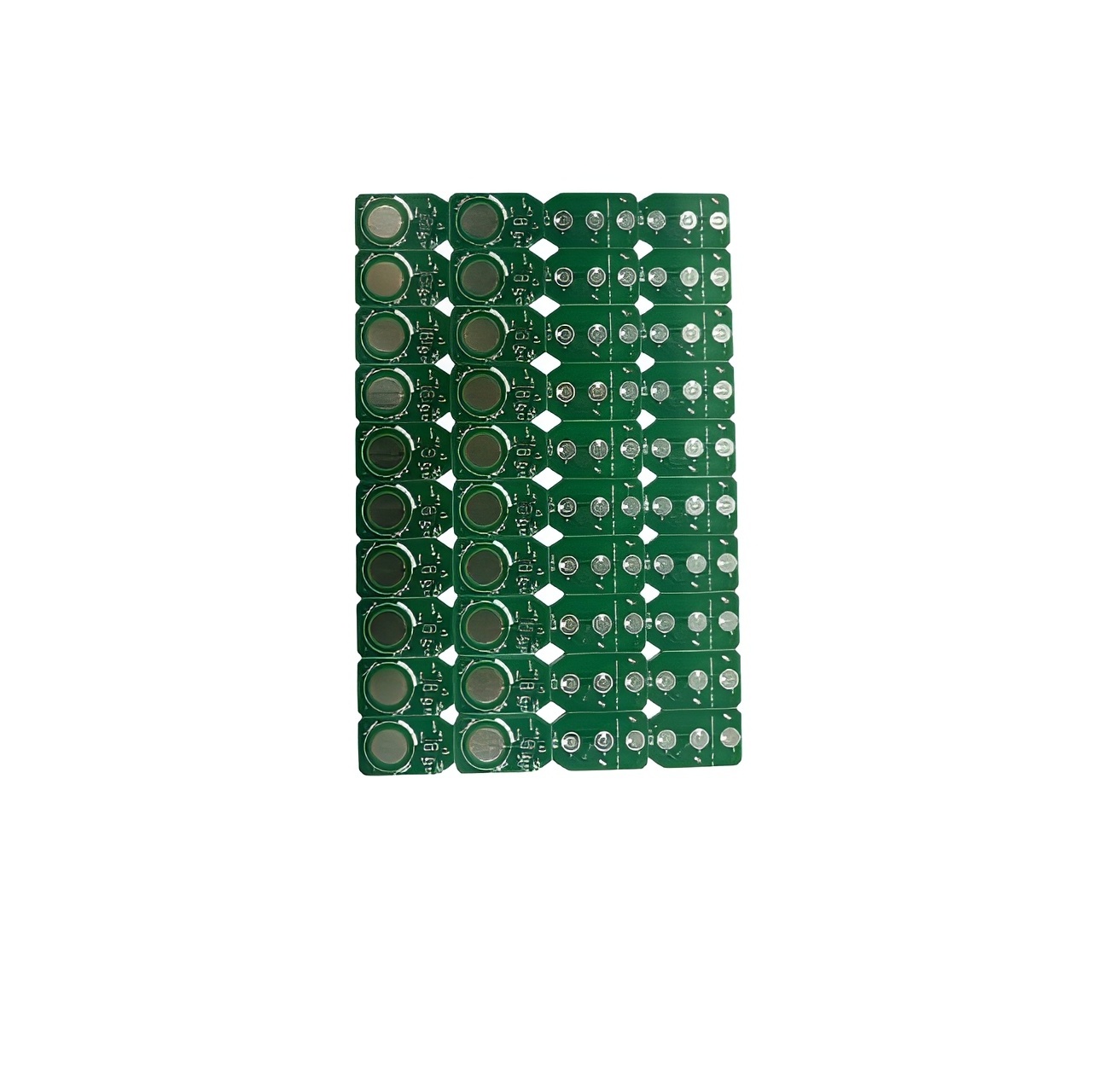

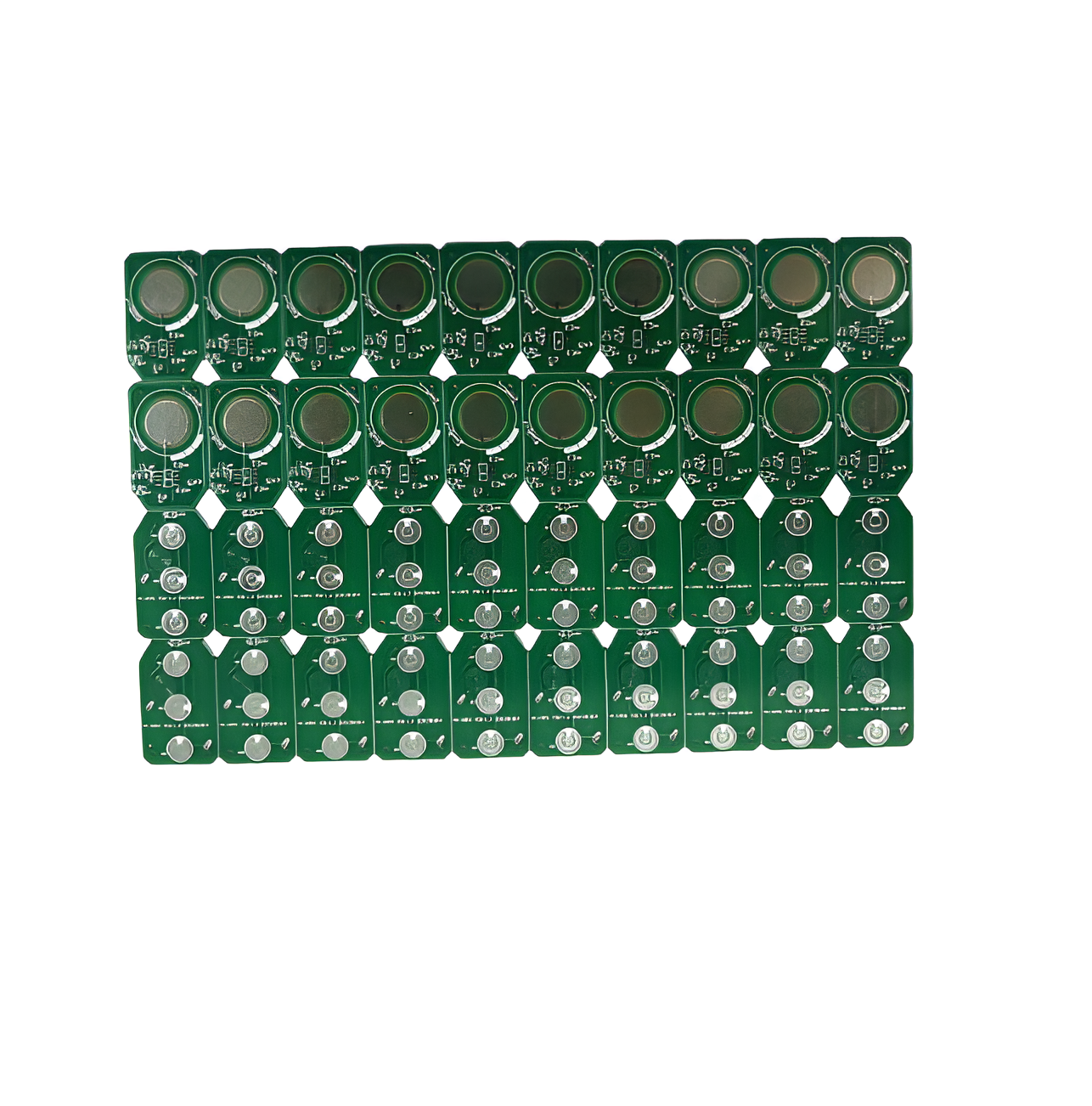

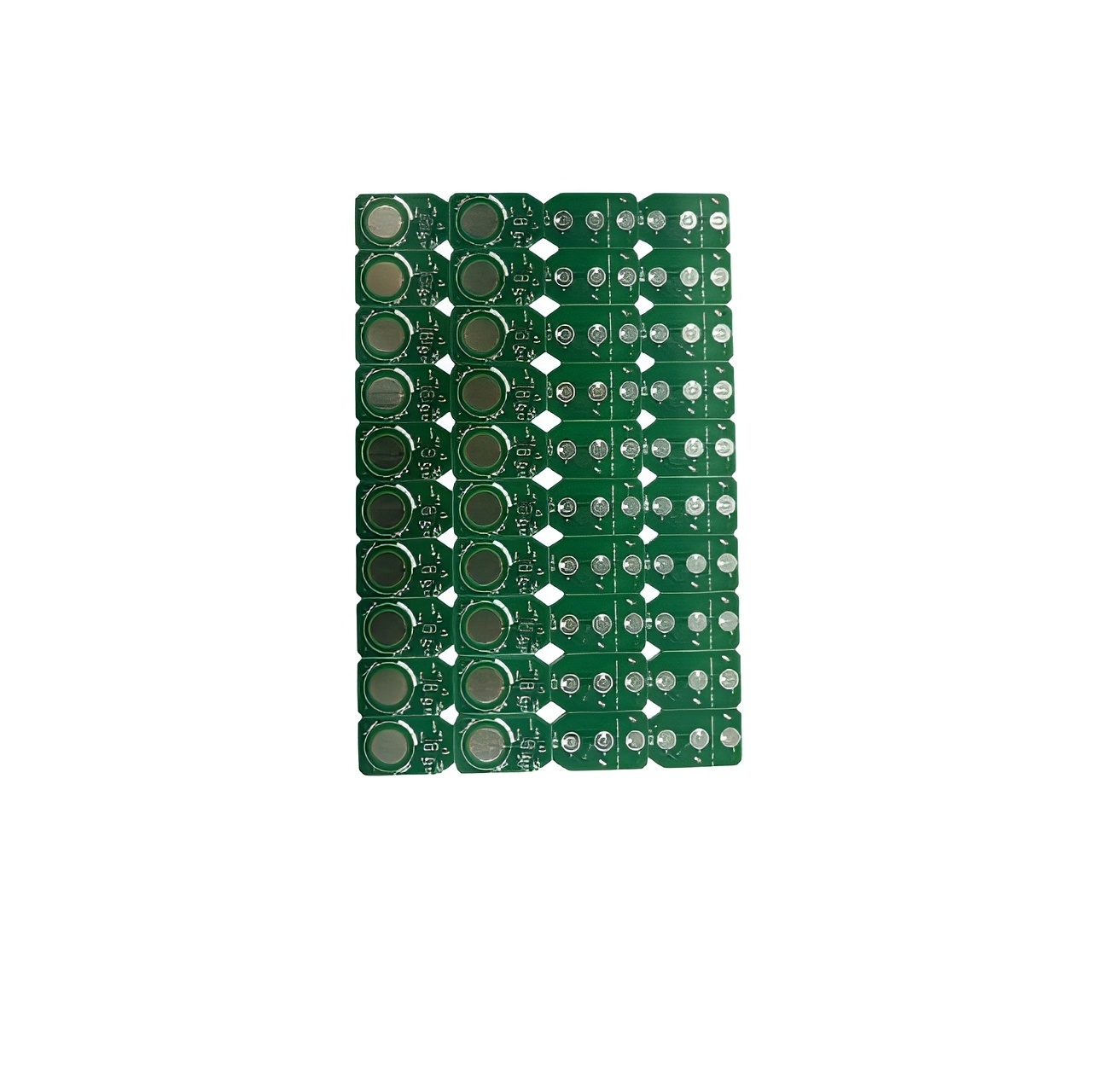

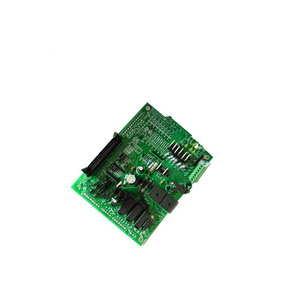

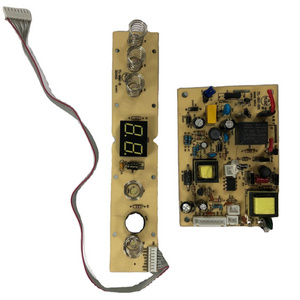

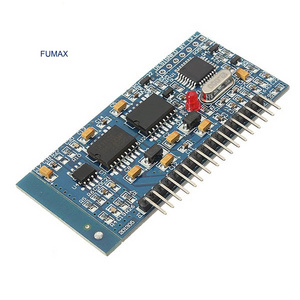

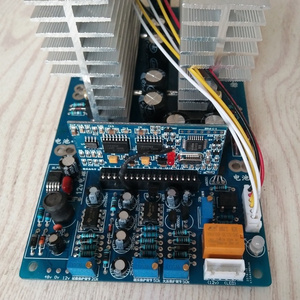

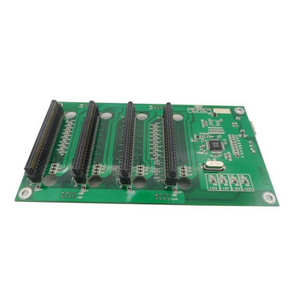

WDXPCB provides a total PCB Supply chain Management solution with over 19 years of experience, which includes PCB engineering,

manufacturing, assembly, electronic product design, and logistics

manufacturing, assembly, electronic product design, and logistics

Quality Policy

: Differentiated production, customer satisfaction.

HSF Policy : Compliance with regulations, green production

Environmental Policy : Compliance with regulations, continuous improvement

HSF Policy : Compliance with regulations, green production

Environmental Policy : Compliance with regulations, continuous improvement