- Product Details

- {{item.text}}

Quick Details

-

Feature:

-

Waterproof, insulated, Rotomolded

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

BORIGHT

-

Model Number:

-

BR-S33

-

Product name:

-

Cooler Box

-

Usage:

-

Fishing Camping Picnic Wine Hunting

-

Color:

-

Customized Color

-

Logo:

-

Accept Customized Logo

-

Function:

-

Keeping Ice

Quick Details

-

Material:

-

LLDPE+PU

-

Use:

-

Food

-

Pattern Type:

-

white

-

Feature:

-

Waterproof, insulated, Rotomolded

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

BORIGHT

-

Model Number:

-

BR-S33

-

Product name:

-

Cooler Box

-

Usage:

-

Fishing Camping Picnic Wine Hunting

-

Color:

-

Customized Color

-

Logo:

-

Accept Customized Logo

-

Function:

-

Keeping Ice

Product Description

|

Rotomolded coolers Features

|

|

|

|

*Capacity

|

33QT, welcome make new molds. Rotational molds cost from USD6000...

|

|

|

*Material

|

Foodgrade LLDPE+PU formed insulation

|

|

|

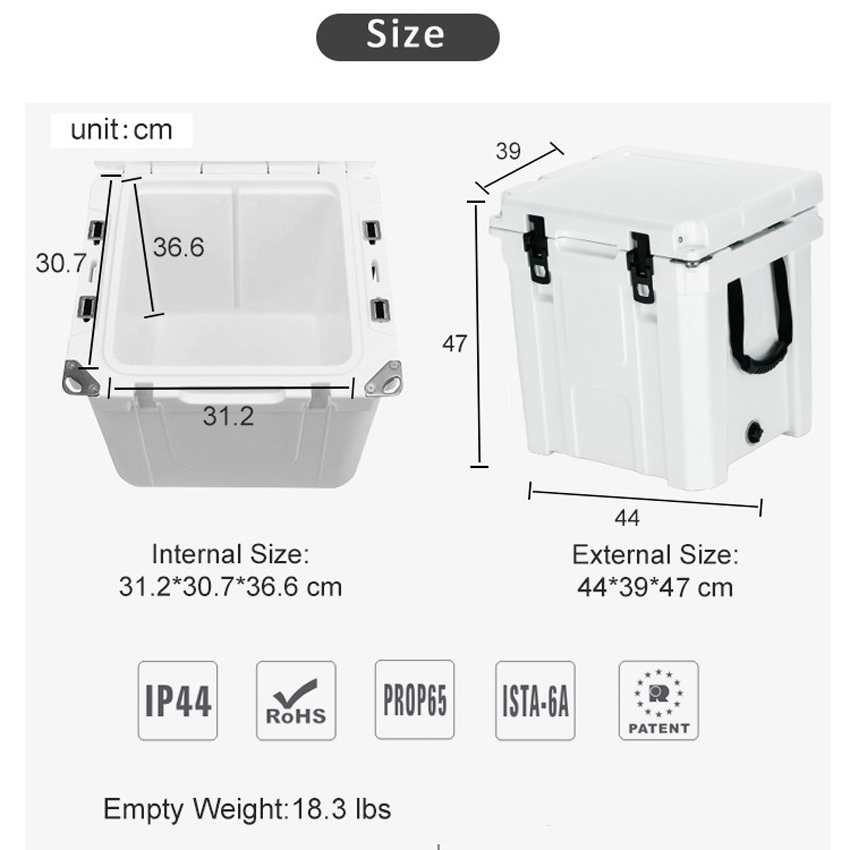

*Outer size

|

44*39*46cm

|

|

|

*Inner size

|

31.2*30.7*36.6cm

|

|

|

*Weight

|

8.5KGS

|

|

|

*Ctn/Packing Size

|

1pc/ OPP bag+1PC/CTN

|

|

|

*MOQ

|

50 pcs

|

|

|

*Leading time of sample

|

1-3 days

|

|

|

*Production time

|

7-25 days

|

|

|

*Rotational molds type

|

Aluminum A356/Wrought aluminum

|

|

|

*Usage

|

Camping, Fishing,Hunting,Traveling, Picnic, Transportion for Fruits,vagtables, seafood, lunch etc

|

|

Detailed Images

Packing&Testing

Related Products

About us&Rotomolding

Detail steps introduction:

step1: Cutting foam according to drawing

step2: According to the 3D drawing make foam mould by CNC machine

step3: Die casting on foam mould make original mould

step4: Drawing size lines and adding pillar for supporting and fixing

step5: CNC precision process

step6: Polishing welding surface process etc for mould

step7: Make mould frame

step8: Adding raw material PE into the mould by equality

step9: Rotating therforming by rotational molding machine

step10: Demold

step1: Cutting foam according to drawing

step2: According to the 3D drawing make foam mould by CNC machine

step3: Die casting on foam mould make original mould

step4: Drawing size lines and adding pillar for supporting and fixing

step5: CNC precision process

step6: Polishing welding surface process etc for mould

step7: Make mould frame

step8: Adding raw material PE into the mould by equality

step9: Rotating therforming by rotational molding machine

step10: Demold

Advantage of rotational molding:

1. Design flexibility for various size and shapes

2. Variety of inserts can be placed

3. The shape of rotational mould can from small to big, simple to complex

4. The thickness and weight can be varied for extra strength requirement

5. Foam material can be filled in products to achieve thermal insulation

6. Variety of colors and surface finishes are available

7. Metal insert mould as integral part

8. UV resistance, anti-impact/corrosion /fade/static/splinter and non-toxic

9. Easy to repaired

10. Text/logo/inserts/foam/electronic tags/threaded outlets and handles can be included

11. Mold cost less than other molding methods

12. Environment friendly

FAQ&CONTACT US

Hot Searches