- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50HZ

-

Power:

-

7.5~15kw

-

Dimension(L*W*H):

-

7800*3000*1720mm

-

Weight:

-

3500~4500kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Product name:

-

Toilet tissue paper making machine

-

Production speed:

-

0~180m/min

-

Model:

-

1575B

-

Jumbo Roll Max Width:

-

1750mm

-

Jumbo Roll Diameter:

-

1100mm

-

Jumbo Roll Inner Diameter:

-

90-140mm

-

Finished Product Diameter:

-

38-48mm

-

Perforation Distance:

-

100-150mm

-

Rewinding Unit:

-

With core or coreless

Quick Details

-

Production Capacity:

-

230m/min

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

JORI

-

Voltage:

-

380V 50HZ

-

Power:

-

7.5~15kw

-

Dimension(L*W*H):

-

7800*3000*1720mm

-

Weight:

-

3500~4500kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Product name:

-

Toilet tissue paper making machine

-

Production speed:

-

0~180m/min

-

Model:

-

1575B

-

Jumbo Roll Max Width:

-

1750mm

-

Jumbo Roll Diameter:

-

1100mm

-

Jumbo Roll Inner Diameter:

-

90-140mm

-

Finished Product Diameter:

-

38-48mm

-

Perforation Distance:

-

100-150mm

-

Rewinding Unit:

-

With core or coreless

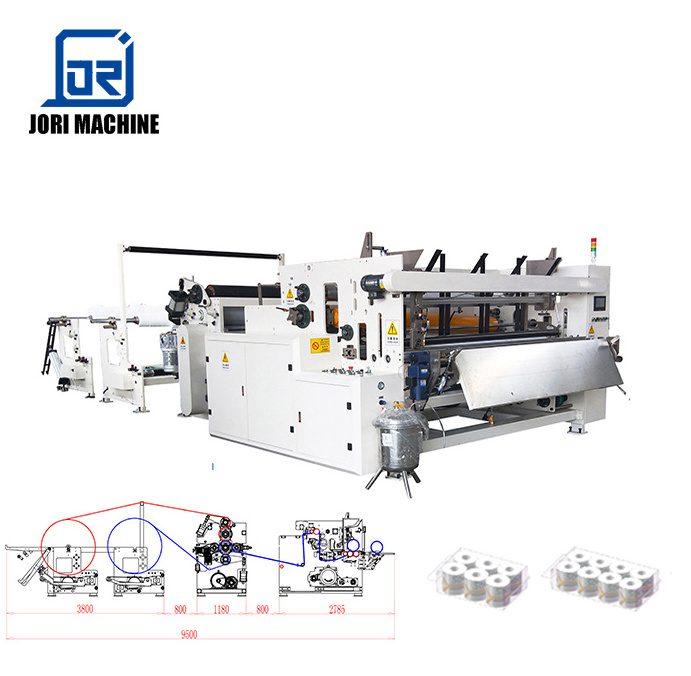

Factory Sale Low Price Tissue Paper Production Line Toilet Paper Making Machine For Sale

Features:

Automatic High Speed Toilet Paper/ Maxi Roll Rewinding Machine is for toilet paper roll/maxi roll processing.

Machine have core feeding unit, can do both with and without core. Raw material from jumbo roll after full embossing or edge embossing, then perforation, end cutting and spray the tail glue become a log. Then it can working with cutting machine and packing machine to become the finished products. The machine is controlled by PLC, people operate it through touch screen, the whole process is automatic, easy to operate, lower the man cost. And Our machine can special-made according to clients' requirements.

Specification:

|

Model

|

1092B

|

1575B

|

1760B

|

2150B

|

2200B

|

2500B

|

2800B

|

||||||

|

Jumbo Roll Max. width

|

1350mm

|

1750mm

|

1880mm

|

2000mm

|

2150mm

|

2400mm

|

2750mm

|

||||||

|

Max. Jumbo Roll diameter

|

2-3 stands (pls specify when order)

Paper gram weight 13-16 g/m2 |

|

|

|

|

|

|

||||||

|

Jumbo Roll Standings

|

Standardφ3"(76.2mm) (Other sizes specified)

|

|

|

|

|

|

|

||||||

|

Data setting

|

HMI

|

|

|

|

|

|

|

||||||

|

Programming controller

|

PLC, touch screen

|

|

|

|

|

|

|

||||||

|

Operate Speed

|

0-230m/min 15000-25000 rolls/8hours

|

|

|

|

|

|

|

||||||

|

Finished Log Outer dia.

|

φ90-140mm

|

|

|

|

|

|

|

||||||

|

Finished Log Inner dia.

|

φ38-76mm

|

|

|

|

|

|

|

||||||

|

Perforation Distance

|

100-150mm

|

|

|

|

|

|

|

||||||

|

Mechanical driving

|

Driving by Stepless gear box

|

|

|

|

|

|

|

||||||

|

Air -system

|

3HP air compressor, min. pressure 5kg/cm2pa ( provide by user)

|

|

|

|

|

|

|

||||||

|

Main driving

|

Frequency conversion speed regulation 7.5-15KW 380V,50HZ

|

|

|

|

|

|

|

||||||

|

Embossing unit

|

Steel to rubber

|

|

|

|

|

|

|

||||||

|

Dimensions

|

6x3x1.7 (length x width x height);(m)

|

|

|

|

|

|

|

||||||

|

Weight

|

3T-4T(depends on the Model you have )

|

|

|

|

|

|

|

||||||

|

Options:

|

|

|

|

|

|

|

|

||||||

|

Embossment Roller

|

Plane, Single Set, Double Sets Can be ordered

|

|

|

|

|

|

|

||||||

|

Color Printing Unit

|

1-2 Colors can be order

|

|

|

|

|

|

|

||||||

|

Lamination Unit

|

Can be Ordered

|

|

|

|

|

|

|

||||||

|

Edge-Embossing Line

|

Steel to Steel Operate by Pneumatic

|

|

|

|

|

|

|

||||||

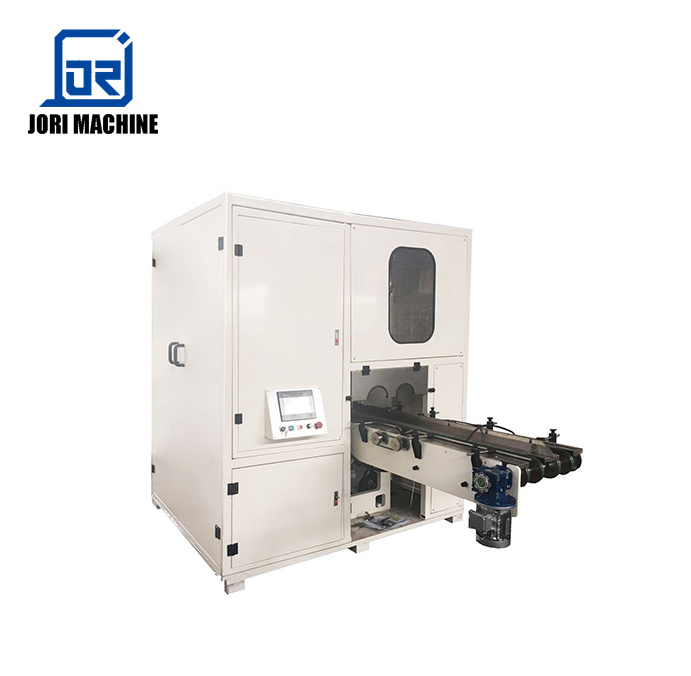

Machine Detail Pictures:

Deco Color Lamination Parts:

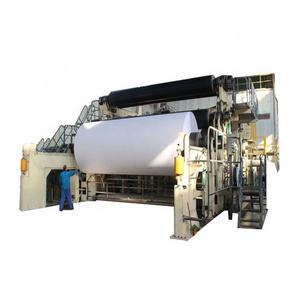

Finished Products:

Pre-Sales Technical Support:

2.Expert sales person will provide you professional suggestion to you based on your correct needs for the configurations of the machines

3.Detailed and clearly explain to you when you come to our factory for visiting before contract.

4.24 Hours online service, 7 Days one week support for you if any technical questions or problems about toilet tissue paper making machine.

After-Sales Service

1

.

Engineers overseas installation and trainning, all our engineers are rich experience for overseas working

2.Guarantee you steady supply for the spare parts with the lower prices