- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SF

-

Voltage:

-

380V 50HZ

-

Power:

-

108kw/h

-

Dimension(L*W*H):

-

1600*1000*1200

-

Weight:

-

700 kg

-

PLC Brand:

-

DELTA

-

Winding diamete:

-

20-200mm

-

Paper roll:

-

3-16 layer

-

Reel speed:

-

3-16m/min

-

Wall thickness:

-

1-8mm

-

Winding head:

-

2-4 heads Single belt

-

Coating method:

-

Double side automatic glue

-

Speed control:

-

Computer frequency conversion

-

Cutting method:

-

Single round knife synchronous automatic cutting

-

Certification:

-

CE ISO

Quick Details

-

Production Capacity:

-

3-20m/min

-

Processing Type:

-

paper tube machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SF

-

Voltage:

-

380V 50HZ

-

Power:

-

108kw/h

-

Dimension(L*W*H):

-

1600*1000*1200

-

Weight:

-

700 kg

-

PLC Brand:

-

DELTA

-

Winding diamete:

-

20-200mm

-

Paper roll:

-

3-16 layer

-

Reel speed:

-

3-16m/min

-

Wall thickness:

-

1-8mm

-

Winding head:

-

2-4 heads Single belt

-

Coating method:

-

Double side automatic glue

-

Speed control:

-

Computer frequency conversion

-

Cutting method:

-

Single round knife synchronous automatic cutting

-

Certification:

-

CE ISO

Product Description

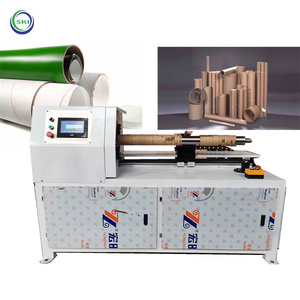

Automatic paper core tube cutting machine label core cutter manual paper core cardboard tube cutter

paper core machine china

adopts the form of a paper tube drum, which is controlled by an electronic operating system. The main machine is composed of paper holder, glue, roller, photoelectric cutting tube, lower tube and a series of processes.

Specification

|

Applicable Industries

|

Manufacturing Plant, Advertising Company

|

|

Condition

|

New

|

|

Type

|

paper tube making machine

|

|

Voltage

|

220-380

|

|

Dimension(L*W*H)

|

3600*2000*1600(mm)

|

|

Weight

|

900 kg

|

|

Warranty

|

1 Year

|

|

Production Capacity

|

Production Capacity

|

|

Key Selling Points

|

High-accuracy

|

|

Max. workable width

|

1600mm

|

|

Warranty of core components

|

6 Months

|

|

Winding diameter

|

20-200mm

|

|

Paper roll

|

3-16 layer

|

|

Reel speed

|

3-16m/min

|

|

Wall thickness

|

1-8mm

|

|

machine size

|

2600*1700*1600

|

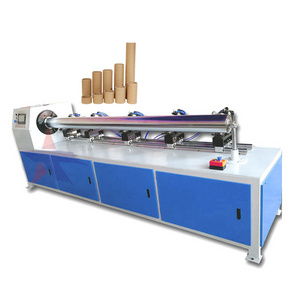

Features of spiral paper core machine:

1. Automatic cutting and automatic paper feeding tube, automatic paper stop function.

2. Automatic speed regulation and automatic recovery when cutting.

3. Computer plc control, with remote control port.

4. Multi-point operation panel or digital remote control function, the operation is very convenient.

Hot Searches