1. The special crank shaft gear transmission and forced lubrication system, using high accuracy & quality alloy steel gear of Osaka, Japan. Hardening abrasive machining, high precision, strength and wear-resistance and steady running.

2. The forced lubrication system is oiled inside, guaranteeing the long term high precision and service life.

3. The power transmission of gripper adopts precise cam box (graduator) from SANDEX Japan, accurate, stable and durable.

4. Mechanical pressure (tons) display device.

5. ASAHI spike gripper is specially designed for the heavy warping board, stable and durable.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LLY PACK

-

Voltage:

-

34KW

-

Weight:

-

32 kg

-

Marketing Type:

-

Hot Product

-

Product name:

-

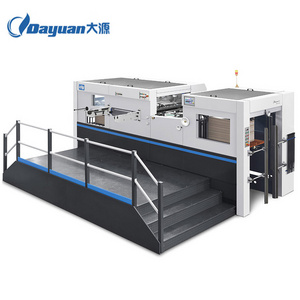

Flatbed Die Cutting Machine

-

Usage:

-

Corrugated Cardboard,Carton Making Factories

-

Maximum paper size:

-

1100X1600mm

-

Minimum paper size:

-

450X600mm

-

Maximum die cutting size:

-

1080X1580mm

-

Standard bite:

-

15(±5)mm

-

Die cutting pressure:

-

350tons

-

Corrugated paper thickness:

-

0.5-5mm

-

Maximum die cutting speed:

-

5000i.p.h

-

Total power consumption:

-

34KW

Quick Details

-

Type:

-

Die-cutting Machine

-

Production Capacity:

-

100 sheets/min

-

Max. workable width:

-

1100mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LLY PACK

-

Voltage:

-

34KW

-

Weight:

-

32 kg

-

Marketing Type:

-

Hot Product

-

Product name:

-

Flatbed Die Cutting Machine

-

Usage:

-

Corrugated Cardboard,Carton Making Factories

-

Maximum paper size:

-

1100X1600mm

-

Minimum paper size:

-

450X600mm

-

Maximum die cutting size:

-

1080X1580mm

-

Standard bite:

-

15(±5)mm

-

Die cutting pressure:

-

350tons

-

Corrugated paper thickness:

-

0.5-5mm

-

Maximum die cutting speed:

-

5000i.p.h

-

Total power consumption:

-

34KW

Features in Performance

1. Exclusively for laminated board and corrugated board with the newest servo-drive feeding system.

2. Accurate die-cutting from E flute to AB fute.

3. Completed stripping is by stripping system and grip edge waste removal device.

4. Excellent adaptability for small and big production.

5. Reliable safety performance and dual safety security device designed. (Air brake and power-off shutdown devices.)

6. All operation is on the exterior of the machine.

7. High Productivity, Precise Die-cutting, Precise Creasing, Smooth Stripping and Convenient Operation.

2. Accurate die-cutting from E flute to AB fute.

3. Completed stripping is by stripping system and grip edge waste removal device.

4. Excellent adaptability for small and big production.

5. Reliable safety performance and dual safety security device designed. (Air brake and power-off shutdown devices.)

6. All operation is on the exterior of the machine.

7. High Productivity, Precise Die-cutting, Precise Creasing, Smooth Stripping and Convenient Operation.

|

Model

|

AP-1600MII-TSG

|

|

Paper size

|

1100X1600mm

|

|

Minimum paper size

|

450X600mm

|

|

Maximum die cutting size

|

1080X1580mm

|

|

Standard bite

|

15(±5)mm

|

|

Frame size

|

1120X1620mm

|

|

Die cutting pressure

|

350tons

|

|

Corrugated paper thickness

|

0.5-5mm

|

|

Maximum die cutting speed

|

5000i.p.h

|

|

Total power consumption

|

34KW

|

|

Total Weight

|

32tons

|

Feeding Section

1. With the newest developed top feeder, guarantees the smooth feeding of big size cardboard, and significantly improves

operation and production ability.

2. Horizontal adjusting device adopts highly precise pull & push type, and the micro-adjusting can control on the operation side.

3. 4 sets of auxiliary feeding wheels ensure the cardboard feeding to the front bench mark precisely.

4. Leveling device is used to feed the cardboard to the front benchmark, and press the bent cardboard to prevent it out of the front baffle.

operation and production ability.

2. Horizontal adjusting device adopts highly precise pull & push type, and the micro-adjusting can control on the operation side.

3. 4 sets of auxiliary feeding wheels ensure the cardboard feeding to the front bench mark precisely.

4. Leveling device is used to feed the cardboard to the front benchmark, and press the bent cardboard to prevent it out of the front baffle.

Press Section

Stripping Section

1. With die quick setting design, operator can finish setting from exterior without entering to the machine.

2. The male and female dies are inserted into the machine directly on the operation side, the male die is motorized locked, the female die is locked by hand crank, saving the time and guaranteeing the safety.

3. Upper and lower frames guarantee the perfect performance of dies. Male and female dies are linkage movement (up and down),

guaranteeing the precise and completed stripping.

4. A crystal plastic film is set between die-cutting and lower frame, preventing the paper from shedding. It can be adjusted by handle according to the size on the die’s production line direction.

2. The male and female dies are inserted into the machine directly on the operation side, the male die is motorized locked, the female die is locked by hand crank, saving the time and guaranteeing the safety.

3. Upper and lower frames guarantee the perfect performance of dies. Male and female dies are linkage movement (up and down),

guaranteeing the precise and completed stripping.

4. A crystal plastic film is set between die-cutting and lower frame, preventing the paper from shedding. It can be adjusted by handle according to the size on the die’s production line direction.

Delivery Section

1. Front and back barriers with side aligning device make receiving tidy.

2. Coordination of side baffles and back baffles can be adjusted by motor based on the production direction.

3. Delivery platform is driven by motor, easy for setting.

4. Temporary receiving device is controlled by servo-actuator, makes delivery simply and easy.

2. Coordination of side baffles and back baffles can be adjusted by motor based on the production direction.

3. Delivery platform is driven by motor, easy for setting.

4. Temporary receiving device is controlled by servo-actuator, makes delivery simply and easy.

Multiple successful installations

FAQ

Q1. Are you manufacturer?

A: Yes. We are manufacturing factory.

Q2. Where is your factory located?

A:Our factory is located in Hegui Industrial Park, Lishui, Nanhai District, Foshan City, Guangdong Province, China.

Q3. What kinds of products do you supply?

A: We provide one-stop solutions for corrugator factories all over the world. All kinds of machine spare parts & consumables for corrugator factories.

Q4. How about your service?

A:.A promptly reply in 12 hours, also contact by email, wechat, whatsapp, etc.

Free usage training before shipping, and professional package to keep the machine fasten during shipment

Q5. Where were your products exported before?

A:Vietnam, Thailand, Myanmar, Philippine, Malaysia, Indonesia, India, Egypt, Emirate, Bahrain, Saudi Arabic, Israel, Russia,

Lithuania, Mexico, Brazil, Argentina, Venezuela, Honduras, Korea and etc

A: Yes. We are manufacturing factory.

Q2. Where is your factory located?

A:Our factory is located in Hegui Industrial Park, Lishui, Nanhai District, Foshan City, Guangdong Province, China.

Q3. What kinds of products do you supply?

A: We provide one-stop solutions for corrugator factories all over the world. All kinds of machine spare parts & consumables for corrugator factories.

Q4. How about your service?

A:.A promptly reply in 12 hours, also contact by email, wechat, whatsapp, etc.

Free usage training before shipping, and professional package to keep the machine fasten during shipment

Q5. Where were your products exported before?

A:Vietnam, Thailand, Myanmar, Philippine, Malaysia, Indonesia, India, Egypt, Emirate, Bahrain, Saudi Arabic, Israel, Russia,

Lithuania, Mexico, Brazil, Argentina, Venezuela, Honduras, Korea and etc

Hot Searches