Low cost, simple processing;

Easy to operation & maintenance;

More chemical & water saving;

Smaller footprint;

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

205kg

-

Size:

-

depending on the model, Customized Size

-

Power:

-

depending on the model

-

Weight (KG):

-

205 kg

-

Product name:

-

Screw Press Dehydrator

-

Application:

-

Solid-liquid Separation

-

Type:

-

Water Filter Parts

-

Usage:

-

Water Treament

-

Function:

-

Water Purification Plant

-

Keywords:

-

Water Filter System

-

Name:

-

Pure Water Treatment Plant

-

Capacity:

-

250L~10000L

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

LK

-

Material:

-

Plywooden box or plastic flim

-

Weight:

-

205kg

-

Size:

-

depending on the model, Customized Size

-

Power:

-

depending on the model

-

Weight (KG):

-

205 kg

-

Product name:

-

Screw Press Dehydrator

-

Application:

-

Solid-liquid Separation

-

Type:

-

Water Filter Parts

-

Usage:

-

Water Treament

-

Function:

-

Water Purification Plant

-

Keywords:

-

Water Filter System

-

Name:

-

Pure Water Treatment Plant

-

Capacity:

-

250L~10000L

Product Overview

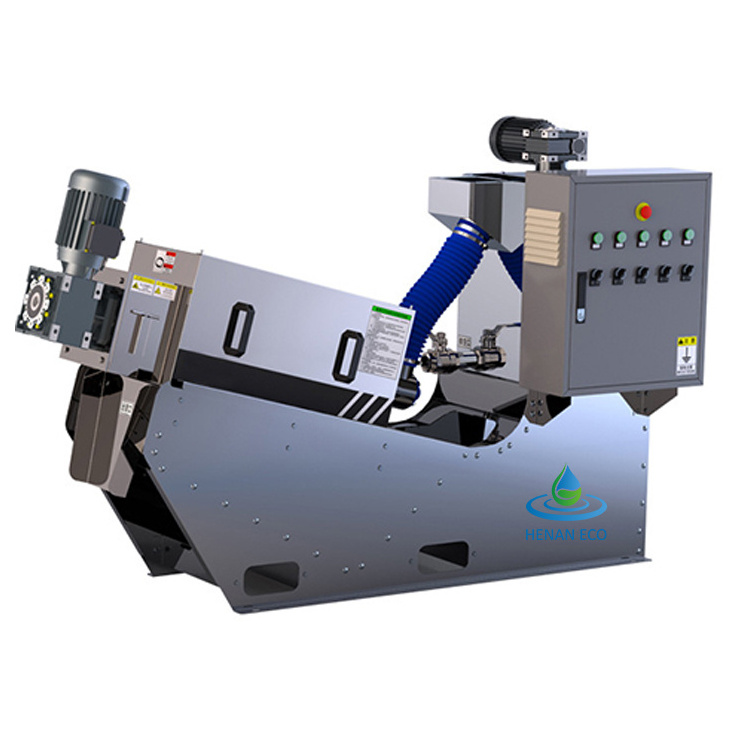

Environmentally friendly dewatering screw press used for solid-liquid separation.

Sludge treatment anti-corrosion press

Sludge Dehydrator Press for Sludge Treatment Price

used for efficient thickening and dewatering of sludge waters. It is intergrating with chemical mixing, sludge thickening & dewatering filtrate collation and aotomatic operation panel.

FEATURES AT A GLANCE

Screw filter press dehydrator

Working Principle

The working principle of

Screw filter press dehydrator

During the operation of the equipment the sludge enters the filter cartridge from the feed inlet and is pushed by the spiral axis spinner to move to the discharge outlet. As the screw pitch between the spiral axis spinners gradually reduces the pressure on the sludge also increases, and the sludge begins to dehydrate under the effect of the differential pressure. The water flows out from the filtration gap between the fixed ring and the movable ring. At the same time the equipment relies on the self-cleaning function between the fixed plate and the movable plate, Clean the filter gap to prevent clogging, and discharge the mud cake from the discharge port under the promotion of the screw shaft after full dehydration.

According to different sludge properties, the company has developed targeted machines, which are more practical in structure and lower in use cost.

PRODUCT SPECIFICATIONS

|

Model

|

Feeding

(m3/h) |

DS

(kg/h) |

Power

(kW) |

Disc

(mm) |

Dimensions

(mm) |

Weight

|

|

DL-131

|

0.2-0.5

|

5-10

|

0.36

|

DN130*1180

|

1870*730*1170

|

250

|

|

DL-132

|

0.4-1.0

|

10-20

|

0.54

|

DN130*1180

|

2000*960*1230

|

350

|

|

DL-133

|

0.6-1.5

|

15-30

|

0.91

|

DN130*1180

|

2000*1190*1230

|

450

|

|

DL-251

|

0.6-1.5

|

15-30

|

0.92

|

DN250*1760

|

2690*880* 1600

|

500

|

|

DL-252

|

1.2-3.0

|

30-60

|

1.47

|

DN250*1760

|

2810*1120*1600

|

800

|

|

DL-253

|

1.8-4.5

|

45-90

|

2.2

|

DN250*1760

|

2810*1360*1600

|

1100

|

|

DL-301

|

1.2-3.0

|

30-60

|

1.3

|

DN300*2220

|

3310*1000*1700

|

750

|

|

DL-302

|

2.4-6.0

|

60-120

|

2.05

|

DN300*2220

|

3500*1300*1700

|

1340

|

|

DL-303

|

3.6-9.0

|

90-180

|

3

|

DN300*2220

|

3700*1650*1700

|

1750

|

|

DL-304

|

4.8-12.0

|

120-240

|

3.75

|

DN300*2220

|

4000*2050*1750

|

2150

|

|

DL-351

|

2.0-5.0

|

50-100

|

1.85

|

DN350*2480

|

3610*1100*1850

|

1150

|

|

DL-352

|

4.0-10.0

|

100-200

|

2.95

|

DN350*2480

|

3820*1490*1850

|

1950

|

|

DL-353

|

6.0-15.0

|

150-300

|

4.4

|

DN350*2480

|

4120*1770*1850

|

2800

|

|

DL-354

|

8.0-20.0

|

200-400

|

5.9

|

DN350*2480

|

4320*2290*1850

|

3700

|

|

DL-401

|

3.2-8.0

|

80-160

|

3

|

DN400*3100

|

4550*1180*2250

|

2050

|

|

DL-402

|

6.4-16.0

|

160-320

|

4.5

|

DN400*3100

|

4870*1710*2250

|

3850

|

|

DL-403

|

9.6-24.0

|

240-480

|

7.5

|

DN400*3100

|

4790*2550*2250

|

5400

|

|

DL-404

|

12.8-32.0

|

320-640

|

9

|

DN400*3100

|

4840*3140*2250

|

7000

|

Successful Project

SALES AND SERVICE NETWORK

FAQ

Q1:

Do you provide OEM service?

A1:

Yes. Any required logos

can be customized according to your needs.

Q2:

Do you offer after-sales service?

A2:

Yes. Engineers available.

Hot Searches