- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Yuxi

-

Voltage:

-

380V/50Hz

-

Dimension(L*W*H):

-

2.6*2*1.9-8.2*4*4.3

-

Power (kW):

-

3

-

Weight (T):

-

2.5

-

Application:

-

Foam, Plastic

-

Type:

-

Shaft Shredder

-

Color:

-

Client's Requirements

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Max.Production Capacity (kg/h):

-

60000

-

Place of Origin:

-

Henan, China

-

Production Capacity (kg/h):

-

2000 - 3000 kg/h

-

Brand Name:

-

Yuxi

-

Voltage:

-

380V/50Hz

-

Dimension(L*W*H):

-

2.6*2*1.9-8.2*4*4.3

-

Power (kW):

-

3

-

Weight (T):

-

2.5

-

Application:

-

Foam, Plastic

-

Type:

-

Shaft Shredder

-

Color:

-

Client's Requirements

-

Marketing Type:

-

Ordinary Product

Products Description

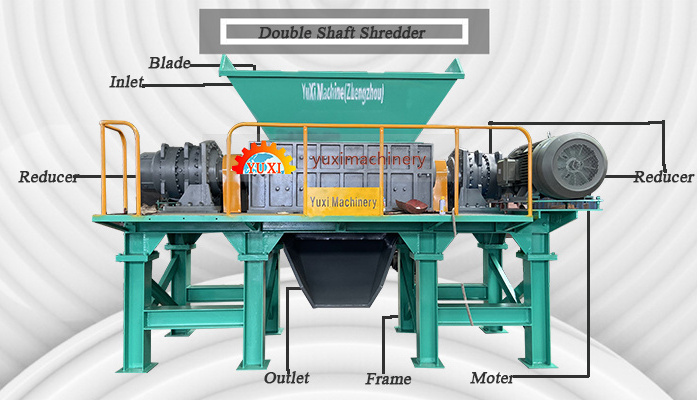

Double Shaft Shredder

The double shaft shredder is a kind of finely broken machine that is used to process unprocessed raw materials or scraps to make them smaller.

Technical Parameter

|

Model

|

YX-600

|

YX-1000

|

YX-1400

|

|

Spindle power

|

4-15*2KW

|

4-37*2KW

|

4-55*2KW

|

|

Spindle speed

|

18-20r/min

|

18-35r/min

|

14-35r/min

|

|

Capacity

|

2-3t/h

|

5-8t/h

|

8-12t/h

|

|

Number of cutter pan

|

26

|

33

|

46

|

|

Diameter cutter pan

|

360

|

360

|

550

|

|

Broken size

|

3-10cm

|

3-10cm

|

3-10cm

|

|

Hopper size

|

820*900mm

|

1200*1000mm

|

2000*2000mm

|

|

Dimensions(mm)

|

2600*2000*1900

|

3000*2000*1900

|

4300*1700*2400

|

|

Weight

|

2.5t

|

5.7t

|

18t

|

Application

Industrial shredder machine can crushed all kinds of materials

(1)

Various hollow containers

: plastic beverage cans, plastic buckets, iron drums, packing boxes, packaging drums.

(2)

Waste home appliances

TV, circuit board, washing machine, refrigerator casing

(3)

Pipe large pipe

, pipe fittings, PE pipe

(4)

Used templates

: wooden pallets, plastic pallets, forklift pallets,

(5) U

sed tire

: trolley tires, truck tires

(6)

Scrap metal

: automobile casing, aluminum alloy, waste cast aluminum, lead in engine casing and steel plate with thickness less than 5mm

(7)

Kitchen waste

, domestic garbage, animal carcass RDF derivatives, medical waste, biological orange pole, garden garbage

(8)

Plastic head material

, paper mill twisted rope.

Some finished product for your reference.

Details Images

Main Parts of Shredder

1.

Rack

It adopts split type casing, which is easy to disassemble and assemble. It is welded with Q345b to make it resistant to abrasion, high in grinding strength and detachable side wall of the box.

2.

Blade

SKD11 high hardness, high wear-resistant eutectic carbide uniform, good toughness, not easy to crack, hardness >62-65HRC after quenching

3.

Motor

Kaifeng pure copper motor.

4.

Reducer

The internal gear of the planetary reducer adopts 20CrMnTi carburizing and quenching and has the characteristics of small volume, light weight, high bearing capacity, long service life, stable operation, low noise.

Features

1.The whole machine is controlled by Siemens PLC through automatic detection, alarm and overload protection functions, which can automatically adjust and control the feed amount

2.Wide range of functions, can shred various materials.

3.The equipment has high speed, high torque, low noise and dust to meet environmental standards.

4.The thickness of the tool and the number of claws can be changed according to different materials

Why Choose Us

1.

Inspection

: Our factory provides customers with raw material test machine.

2.

Free wearing parts

: Transmission belt, vulnerable bearing, grease nozzle, switch converter, bottom screen, vibration spring.

3.

Installation service

: For the production lines,need 2 people (will take 25-30 days, according to the size of the production line, the ability of the local engineer of the customer)

Single set machine routine does not need to be installed, provide installation drawings, operation video, engineer online guidance, if required to install, send 1 person (10-15 days)

4.

Global inspection service

: Our company provides a free inspection service within one year from the end of installation.

5.

Repair service

: If the abnormal damage occurs during the warranty period, the engineer maintenance fee will be paid.

Hot Searches