1.

W

idest range of screening

: applicable to all kinds of particles, powder, and slurry filter.

2.

The mesh not block:

a variety of specially designed screen of the cleaning device make the probability of blocking the mesh approach the minimum.

3.

Single layer and multi-layer separation

; Single layer filtration, once to achieve the requirements

4.

Easy to change the screen

; no deformation of the mesh, long service life of screen, high efficiency

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/415V/440V or Customized

-

Dimension(L*W*H):

-

94*94*105cm

-

Weight:

-

167 KG

-

Layer(s):

-

1-5 Layers

-

Cleaning system:

-

Bouncing Ball or Ultrasonic system

-

Surface treatment:

-

Mirror Polishing or wire drawing

-

Function:

-

Screening\separation\sorting\sieving

-

Material:

-

Carbon Steel/Stainless Steel 304/316L

-

Noise Level:

-

Low 75dB

-

Customization:

-

Available

-

Applicable Material:

-

Powder Raw Material

-

Quality Guarantee:

-

Test video before delviery.

-

After-sales Service Provided:

-

Online Video Technical Support

Quick Details

-

Type:

-

Circular

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Xianchen

-

Voltage:

-

220V/380V/415V/440V or Customized

-

Dimension(L*W*H):

-

94*94*105cm

-

Weight:

-

167 KG

-

Layer(s):

-

1-5 Layers

-

Cleaning system:

-

Bouncing Ball or Ultrasonic system

-

Surface treatment:

-

Mirror Polishing or wire drawing

-

Function:

-

Screening\separation\sorting\sieving

-

Material:

-

Carbon Steel/Stainless Steel 304/316L

-

Noise Level:

-

Low 75dB

-

Customization:

-

Available

-

Applicable Material:

-

Powder Raw Material

-

Quality Guarantee:

-

Test video before delviery.

-

After-sales Service Provided:

-

Online Video Technical Support

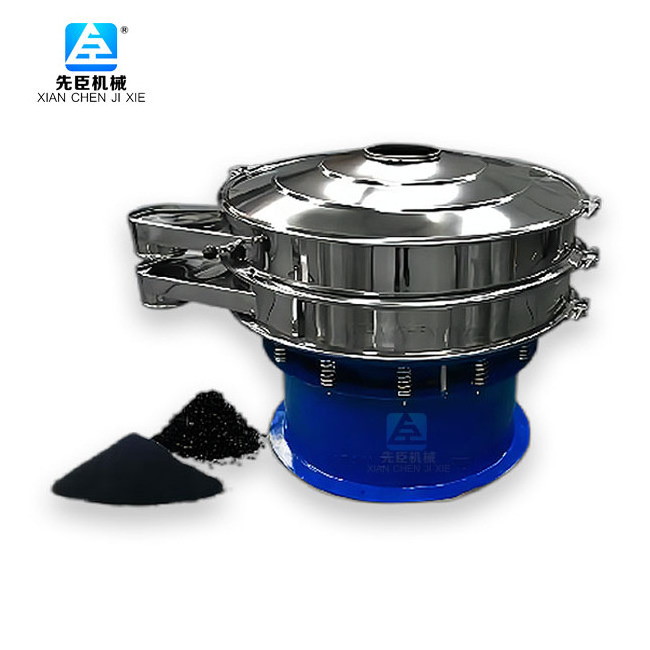

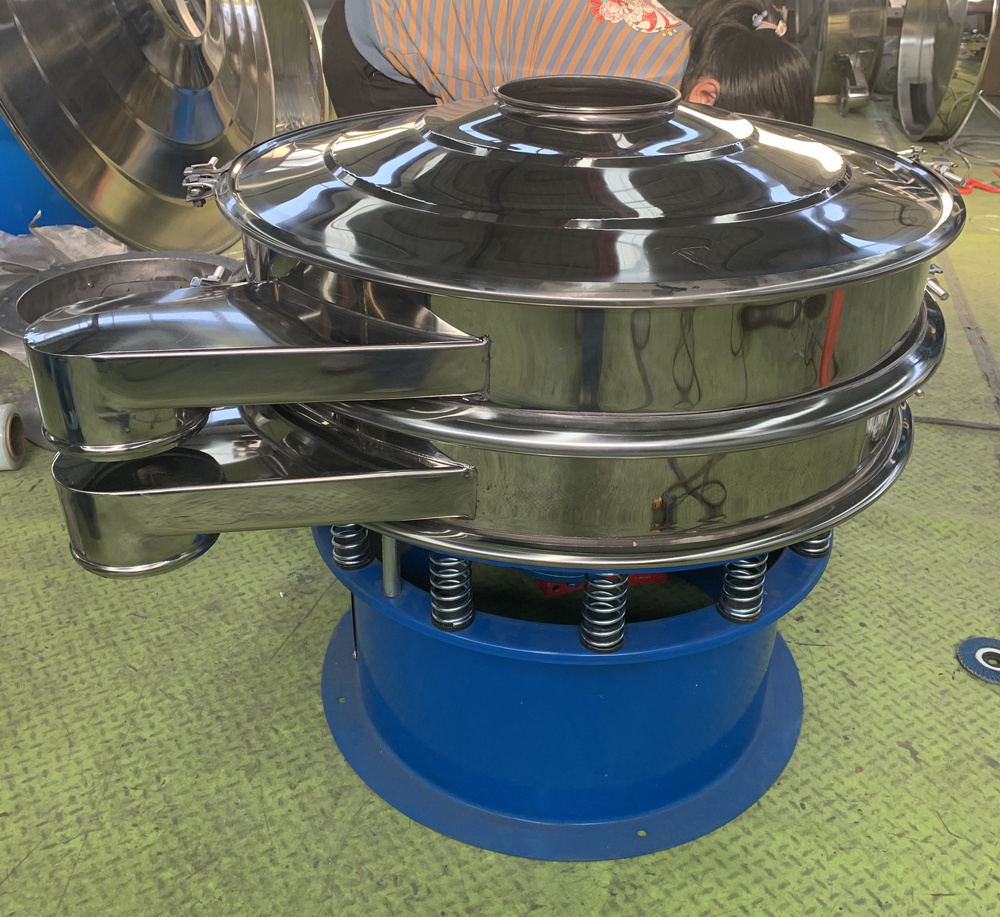

Product Overview

Overview of rotary vibration screen

XC series three-D rotary vibrating screen is a special screening equipment with international level, high precision and fine particle on the basis of advanced technology from home and abroad. Its advantages are as follows: fully closed, no dust emission, continuous operation; high screening precision, efficiency and utilization rate of screen; small volume, light in weight, start quickly, low noise; easy operation, convenient maintenance, long service life of screen; the discharge port direction changed along the circumferential direction. The machine is widely used in screening fine powder, micro powder, submicron powder, bar, dry and wet materials.

FEATURES AT A GLANCE

Right elevation

Left elevation

Front elevation

PRODUCT SPECIFICATIONS

|

Model

|

Power

|

Screen diameter

|

Effective area

|

Layer

|

|

XC600-1S

|

0.55kw

|

560mm

|

0.2375 m

2

|

1 layer sieve,2 outlets

|

|

XC600-2S

|

Bucket capacity

|

2.8 M3

|

|

2 layer sieves,3 outlets

|

|

XC600-3S

|

Operating weight

|

125Ton

|

|

3 layer sieves,4 outlets

|

|

XC800-1S

|

0.75kw

|

760mm

|

0.4416 m

2

|

1 layer sieve,2 outlets

|

|

XC800-2S

|

Max. breakout force

|

96kN

|

|

2 layer sieves,3 outlets

|

|

XC800-3S

|

Tipping load

|

60kN

|

|

3 layer sieves,4 outlets

|

|

XC1000-1S

|

0.75kw

|

930mm

|

0.6789 m

2

|

1 layer sieve,2 outlets

|

|

XC1000-2S

|

1.1kw

|

|

|

2 layer sieves,3 outlets

|

|

XC1000-3S

|

1.5kw

|

|

|

3 layer sieves,4 outlets

|

|

XC1200-1S

|

1.1kw

|

1130mm

|

1.0382 m

2

|

1 layer sieve,2 outlets

|

|

XC1200-2S

|

1.5kw

|

500N.m

|

|

2 layer sieves,3 outlets

|

|

XC1200-3S

|

1.75kw

|

|

|

3 layer sieves,4 outlets

|

|

XC1500-1S

|

2.2kw

|

1430mm

|

1.6052 m

2

|

1 layer sieve,2 outlets

|

|

XC1500-2S

|

|

|

|

2 layer sieves,3 outlets

|

|

XC1500-3S

|

|

|

|

3 layer sieves,4 outlets

|

|

XC1800-1S

|

2.2kw

|

1730mm

|

2.3523 m

2

|

1 layer sieve,2 outlets

|

|

XC1800-2S

|

2.2kw

|

|

|

2 layer sieves,3 outlets

|

|

XC1800-3S

|

3.0kw

|

|

|

3 layer sieves,4 outlets

|

|

XC2000-1S

|

3.0kw

|

1930mm

|

2.9255 m

2

|

1 layer sieve,2 outlets

|

|

XC2000-2S

|

1.5kw

|

|

|

2 layer sieves,3 outlets

|

|

XC2000-3S

|

|

|

|

3 layer sieves,4 outlets

|

PRODUCT CONFIGURATION

Successful Project

Project in Thailand

Project in India

Project in Russia

Product related industries

Product related industries:

Our Certificate

Our Exhibition

About the Company

About the Company:

Xinxiang Xianchen Vibration Machinery Co,. Ltd ,

which is established in the year of 2009, located in China biggest machinery manufacture base Henan province, is a professional vibration machinery manufactures which specializes in the production of sieving equipments, conveying equipments, crushing equipments and feeding equipments as well as relevant parts. we committed to solve all kinds of sieving problem.

Our tenet: "market oriented, technology based, quality of survival, innovation and development ".

Our Service:

1 .Design as your request

2.Any problems, please feel free to tell us

3.We will offer you the perfect design with competitive price

4. Provide technical support unconditionally.

5. Providing solutions according to the real situation.

2.Any problems, please feel free to tell us

3.We will offer you the perfect design with competitive price

4. Provide technical support unconditionally.

5. Providing solutions according to the real situation.

FAQ

FAQ:

1.How about the quality of your product?

a.Our products manufactured strictly according to national and international standard.

b. We take a test on every product before delivery.

Note: You had better send us the pictures you have ever used.

2.How about price of this product?

a. We can give the lowest price than market one.

b. We do quotation as soon as possible for any customer.

c. Discount can be given according to quantity.

Hot Searches