- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Wansheng

-

Model Number:

-

FRP sheet

-

Surface Treatment:

-

Gelcoat

-

Name:

-

FRP Sheet

-

Thickness:

-

1.0-3.0mm

-

Length:

-

120m In Roll Or Customised

-

Colors:

-

RAL-scale Or Customised

-

Material:

-

FRP Resin Fiberglass

-

Sample:

-

Freely Supplied

-

Surface:

-

Glossy/ 50% Glossy/Embossing

-

Advantage:

-

Stress Corrosion Resistance Etc

-

MOQ:

-

200㎡

-

Packing:

-

Customized Packings

Quick Details

-

Application:

-

Construction

-

Technique:

-

Once-shaping machining sheet

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Wansheng

-

Model Number:

-

FRP sheet

-

Surface Treatment:

-

Gelcoat

-

Name:

-

FRP Sheet

-

Thickness:

-

1.0-3.0mm

-

Length:

-

120m In Roll Or Customised

-

Colors:

-

RAL-scale Or Customised

-

Material:

-

FRP Resin Fiberglass

-

Sample:

-

Freely Supplied

-

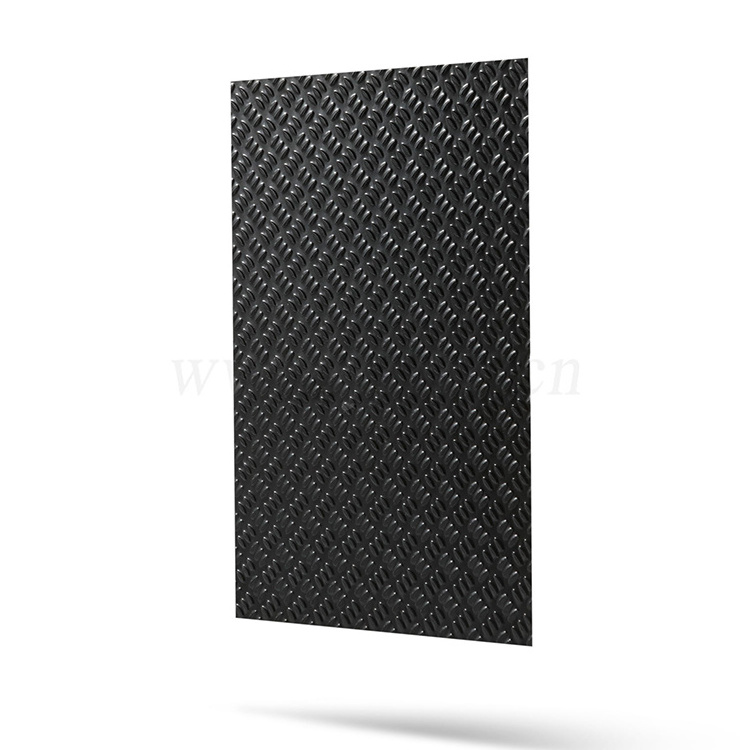

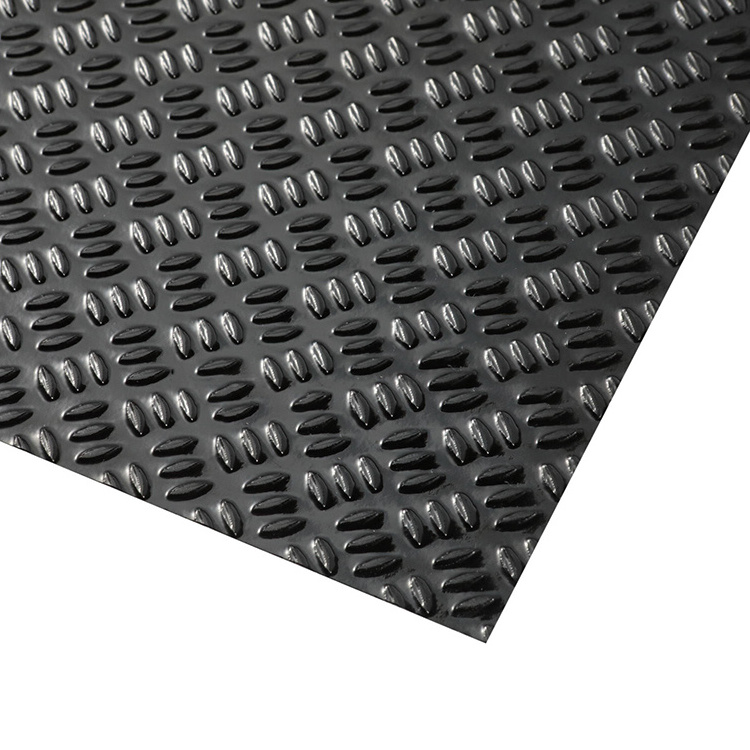

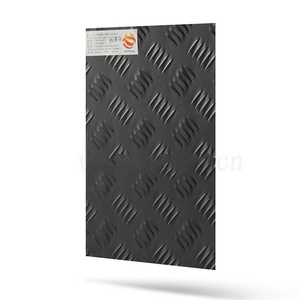

Surface:

-

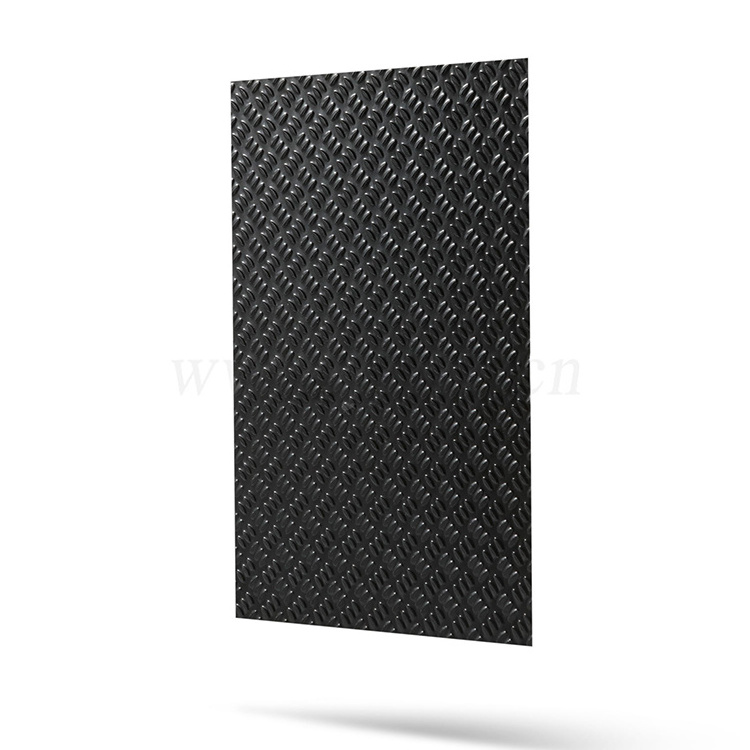

Glossy/ 50% Glossy/Embossing

-

Advantage:

-

Stress Corrosion Resistance Etc

-

MOQ:

-

200㎡

-

Packing:

-

Customized Packings

|

Information

|

|

|

|

Width:

|

≤3.2m

|

|

|

Thickness:

|

1.0-3.0mm

|

|

|

Length:

|

Customized

|

|

|

Surface:

|

Smooth or embossed

|

|

|

Color:

|

White, black, green, yellow, customized

|

|

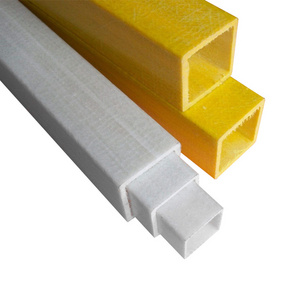

FRP (glass fiber reinforced plastic) is a composite material formed by composite processing of synthetic resin and glass fiber.

As a new type of material, FRP sheets have replaced traditional metal materials in many fields.

Basic Structure of Gelcoat FRP Sheets

* Middle (Fiberglass)

Fiberglass mat or fiberglass fabric has stronger bonding force with resin, is more soluble in styrene, and endows the product with the characteristics of high strength, light weight and good toughness. Good impact resistance properties are also well represented.

* Back Side (Resin)

The substrate surface of the FRP panel is flat, and clean, with no air hole, no crack, no scratch, and adhesion is better.

The two continuous FRP sheet production lines are self-designed and self-made with the domestic leading level. The lines have been set up with the annual production capacity of 2.4 million square meters.

We

have high efficiency sales team, professional engineer support and professional R&D test center, which attract customers from all over the world. We export to over 20 countries, including Australia, United States, Europe, Brazil, India, Singapore, New Zealand Thailand and so on.

Hot Searches