Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sevenstars

-

Voltage:

-

380V 50hz

-

Dimension(L*W*H):

-

based on different machine models

-

Power (kW):

-

90

-

Weight:

-

20 KG

-

Name:

-

Pe DWC Wall Corrugated Pipe Making Machine

-

Raw material:

-

PP PE

-

After-sales Service Provided:

-

1 Year

-

Usage:

-

Plastic Pipe Extrusion

-

Keywords:

-

Corrugated Pipe Making Machine

-

Final product:

-

Pe DWC Wall Corrugated Pipe

-

Processing Type:

-

Exturding Machine

-

Product Type:

-

Extrusion Production

-

Product name:

-

Corrugated Pipe Making Machine

-

Material:

-

PP PE LDPE HDPE

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

120 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sevenstars

-

Voltage:

-

380V 50hz

-

Dimension(L*W*H):

-

based on different machine models

-

Power (kW):

-

90

-

Weight:

-

20 KG

-

Name:

-

Pe DWC Wall Corrugated Pipe Making Machine

-

Raw material:

-

PP PE

-

After-sales Service Provided:

-

1 Year

-

Usage:

-

Plastic Pipe Extrusion

-

Keywords:

-

Corrugated Pipe Making Machine

-

Final product:

-

Pe DWC Wall Corrugated Pipe

-

Processing Type:

-

Exturding Machine

-

Product Type:

-

Extrusion Production

-

Product name:

-

Corrugated Pipe Making Machine

-

Material:

-

PP PE LDPE HDPE

General Introduction

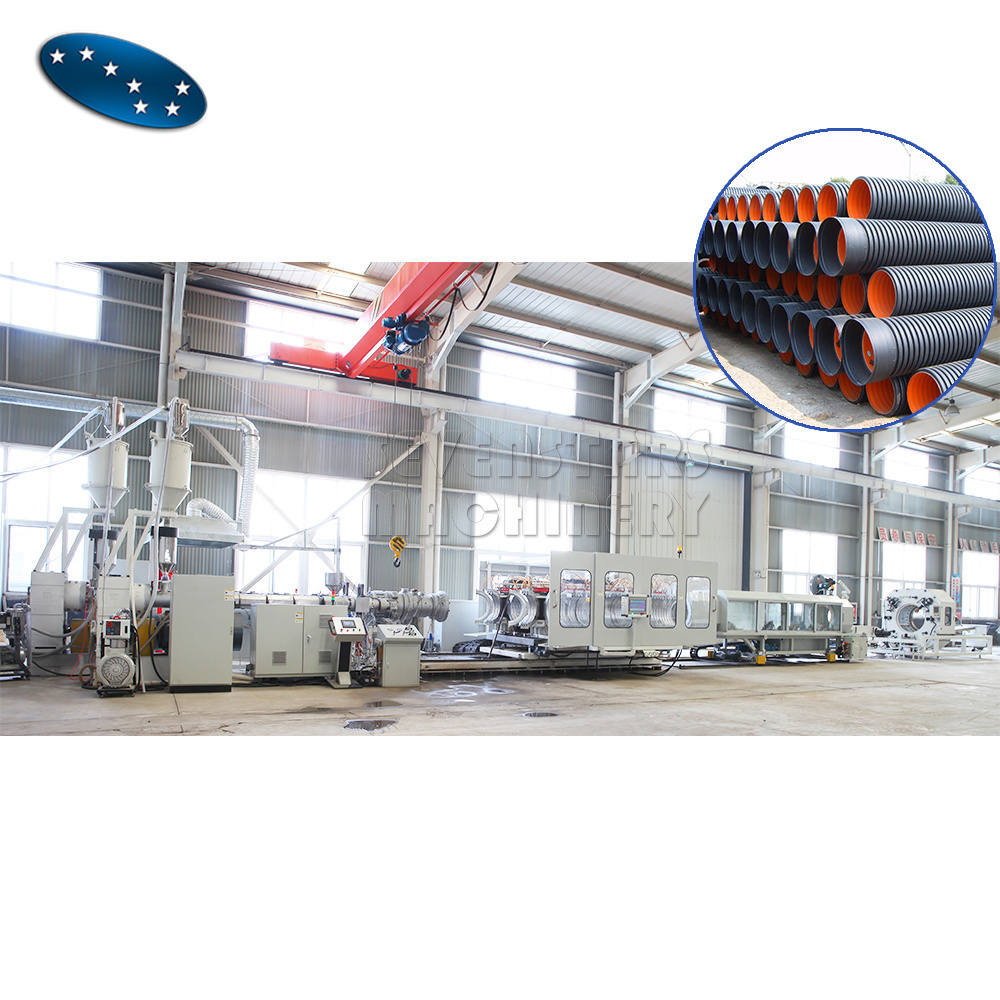

High Speed Double Wall Corrugated Pipe Extrusion Line

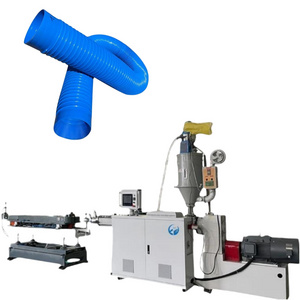

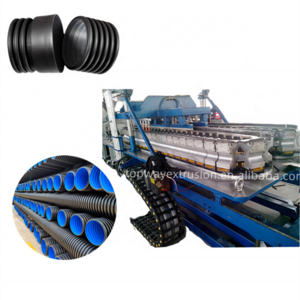

This line is used to produce Double wall corrugated pipes. it has two units of singles screw extruder Raw material is PE/PP granule/pellets.

This machine use PE material to produce big diameter double wall corrugated pipe.The pipe has light weight,strong impact resistant capability,high ring stiffness and corrosion resistance. And widely used in

threading pipe, drain pipe, power pipe.

Detail Description

|

Model

|

Pipe Diameter(MM)

|

Extruder Model

|

Main power(kw)

|

Mold Pairs

|

|

BDX-180H

|

OD40-OD180

|

SJ65/33&SJ75/33

|

55/90

|

18/36

|

|

BDX-200H

|

OD40-ID200

|

SJ65/33&SJ75/33

|

55/90

|

48/36

|

|

BDX-300H

|

OD110-ID300

|

SJ75/33&SJ90/33

|

90/132

|

36

|

|

BDX-600H

|

OD200-ID600

|

SJ90/33&SJ120/33

|

132/185

|

36

|

|

BDX-800H

|

ID400-ID800

|

SJ120/33&SJ150/33

|

185/315

|

36

|

High speed extruder

The extruder is consist of screw, barrel, vacuum automatic feeder, hopper dryer, gearbox and motor. Spiral screw with mixing section, which improve the output and plasticization effect. Special for PE/PP material efficient extrude. Water cooling system with automatic temperature control is at the material inlet port of the barrel. The hopper dryer adopt drying and storing material integrated design, also with automatic temperature control and intelligent display.

All the parts be made by reputed manufacturer and provided by reputed supplier.

All the parts be made by reputed manufacturer and provided by reputed supplier.

Water Cooling Corrugat or

Corrugator is used to place and move corrugated mold. Vacuum is created to absorb outer layer into corrugated mold to formcorrugate shape. By moving corrugated mod, pipe is also pulled out from corrugator.

The horizontal structure layout of the corrugated pipe forming machine ensures higher rigidity, lower center of gravity, and smoother operation.

Spray Cooling Tank

The box is made of stainless steel and designed with a double-sided side open structure, making it easy to operate and maintain. Cooling the pipe and use a strong blow drying device to completely remove cooling water from the surface of the pipe.

Cutting Machine

Adopting chip free cutting and pneumatic feed mechanism, with high accuracy, ensuring a flat cross-section. Universal clamping mechanism, with automatic centering and no need to adjust the clamping sleeve when changing specifications

Hot Searches