- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Office Building

-

Design Style:

-

Modern

-

Weight:

-

Custom

-

Chemical Composition:

-

Carbon

-

Place of Origin:

-

China

-

Material:

-

Carbon steel

-

Thickness:

-

0.12 - 1.50 mm

-

Width:

-

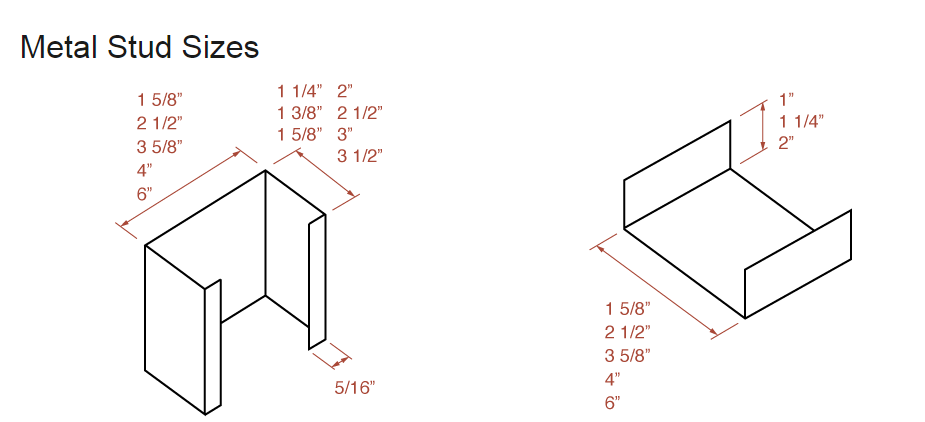

1-5/8", 2-1/2", 3-5/8", or Custom

-

Length:

-

2m - 12m

-

Standard:

-

AiSi, ASTM, DIN, GB, JIS

-

Surface treatment:

-

Galvanized

-

Process:

-

Plain or Slotted

-

Main Application:

-

Drywall, Partition, Interior Wall Framing

-

Delivery time:

-

25 - 30 days

-

MOQ:

-

10 Tons

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support, Return and Replacement

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

Office Building

-

Design Style:

-

Modern

-

Weight:

-

Custom

-

Chemical Composition:

-

Carbon

-

Place of Origin:

-

China

-

Material:

-

Carbon steel

-

Thickness:

-

0.12 - 1.50 mm

-

Width:

-

1-5/8", 2-1/2", 3-5/8", or Custom

-

Length:

-

2m - 12m

-

Standard:

-

AiSi, ASTM, DIN, GB, JIS

-

Surface treatment:

-

Galvanized

-

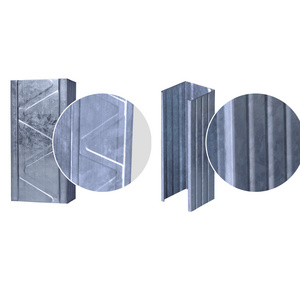

Process:

-

Plain or Slotted

-

Main Application:

-

Drywall, Partition, Interior Wall Framing

-

Delivery time:

-

25 - 30 days

-

MOQ:

-

10 Tons

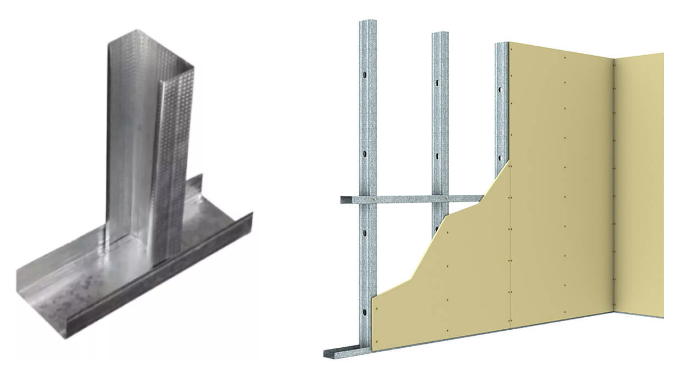

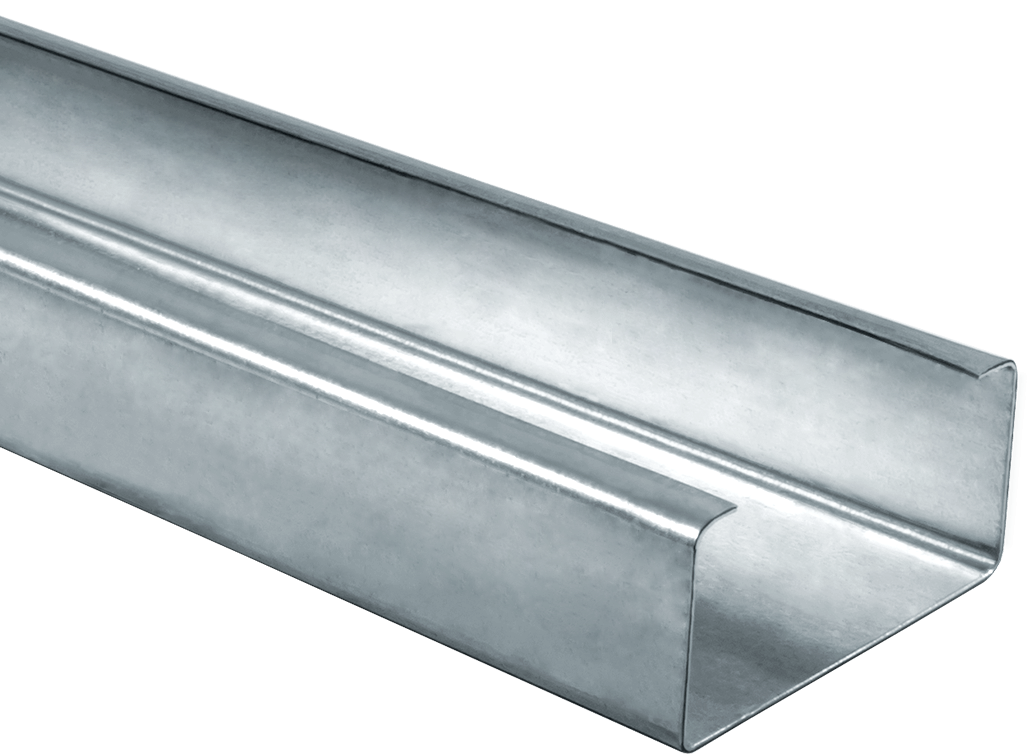

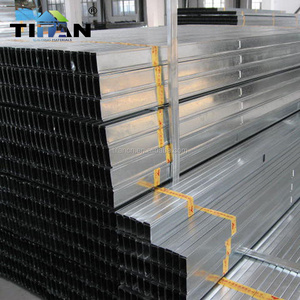

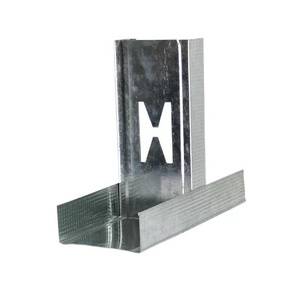

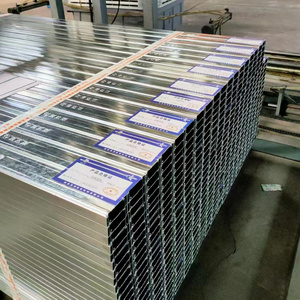

3-5/8" 20 Gauge Metal Stud and Track for Drywall Partition Interior Galvanized Steel Stud Metal Framing Studs

Light gauge metal studs are made of cold-formed steel, used to carry dead loads such as interior wall systems, soffits, corridor ceilings, and finishes like plaster or gypsum wallboard.

We offer Light gauge steel studs and tracks in various widths and thicknesses depending on the drywall framing in the building design.

Typically, light-gauge steel studs will be 25 or 20-gauge material. The most common size stud is a 3 5/8" wide stud. Combined with a layer of 5/8" gypsum wall board on both sides will give a 4 7/8" thick wall. Studs can be anywhere from 8’0” to 24′ in length – or longer, while tracks typically come in 10’ lengths.

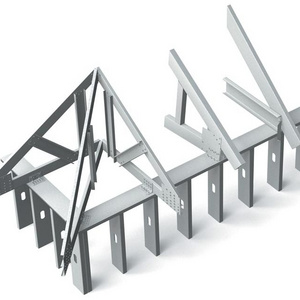

Light Gauge Steel Studs and Tracks

Light gauge steel studs are attached at the bottom track and top track with screws.

Bottom and top track are installed horizontally along the floor and underside of the structure.

Light gauge steel track material typically matches the thickness of the studs they support. For example, a wall partition with 20 gauge studs would also include 20 gauge bottom and top track in most cases.

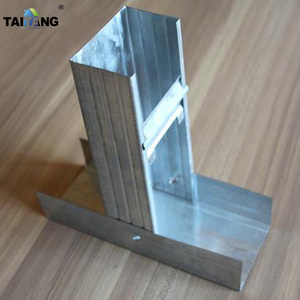

There’s a variety of light gauge steel track products, depending on the application. A few common types of top track include 2″ deep leg track, slotted deflection track, and fire track.

Studs and tracks comprise the majority of light gauge steel used in an interior framing job. Both components are measured and cut like wood studs, but light gauge steel can be cut with aviation snips and bent to shape. Once tracks are fixed to the floors and ceiling, studs are slid and fixed into the steel tracks with framing screws.

Benefits of Light Gauge Metal Framing Stud

- Strength and Stability : Steel studs, tracks, and channels can be ordered in specific quantities with exact measurements from steel roll formers, creating less waste. Once they arrive at a job site, most steel studs for wall framing fit together, so they’re easily stackable.

- Won’t Rot, Resists Mold, Termite Proof : Unlike wood, light gauge steel is dampproof and won’t rot. Steel doesn’t easily hold mold or harbor insects. It won’t warp from water damage or burn up.There is the potential for the steel to rust, but much of the steel used in construction has corrosion-resistant metal finishes to minimize the risks of rust.

-

Durability

Relative to its size, steel is stronger and can therefore support more weight than wood.

When using light gauge steel studs for interior framing, you can have wider stud spacing than lumber.

In some cases, light gauge studs can be spaced as much as 24″ on center. The increased drywall gypsum panels-to-steel framing ratio helps mitigate sound transmission through wall partitions.

Light gauge steel studs also have lateral bracing and bridging for extra support and outstanding strength if the design requires it.

-

Environmentally Friendly

Metal stud framing is made with recycled material. As one of the most important factors to architects and building designers , environmentally friendly material is becoming an attractive feature in new construction projects.

Applications:

Light-gauge steel studs, and most metal studs, have historically seen their use limited to commercial buildings and commercial construction. The invention of steel framing building techniques, along with massive structural steel, created the rise of the skyscraper and the modern city. The convenience of roll-formed studs, which can come pressed and cut to the size you specify with holes punched for plumbing and electrical access, has led to light gauge steel framing becoming more popular.More residential spaces are designed with light gauge steel studs than ever. However, it’s most common to see metal studs in large construction projects in commercial construction.