- Product Details

- {{item.text}}

Quick Details

-

Mold Height(mm):

-

150 - 400 mm

-

Ejector Number:

-

5

-

Ejector Stroke(mm):

-

125 mm

-

Ejector Force(kN):

-

50 kN

-

Theoretical Shot Volume(cm³):

-

180 cm³

-

Injection Rate (g/s):

-

98 g/s

-

Injection Weight (g):

-

162 g

-

Screw Speed (rpm):

-

1 - 190 rpm

-

Screw diameter (mm):

-

38 mm

-

Screw L/D Ratio:

-

20.5

-

Distance between Tie Bars:

-

385*350mm

-

Weight (KG):

-

3400 kg

-

Place of Origin:

-

Jiangsu, China

-

Open Stroke(mm):

-

320 mm

-

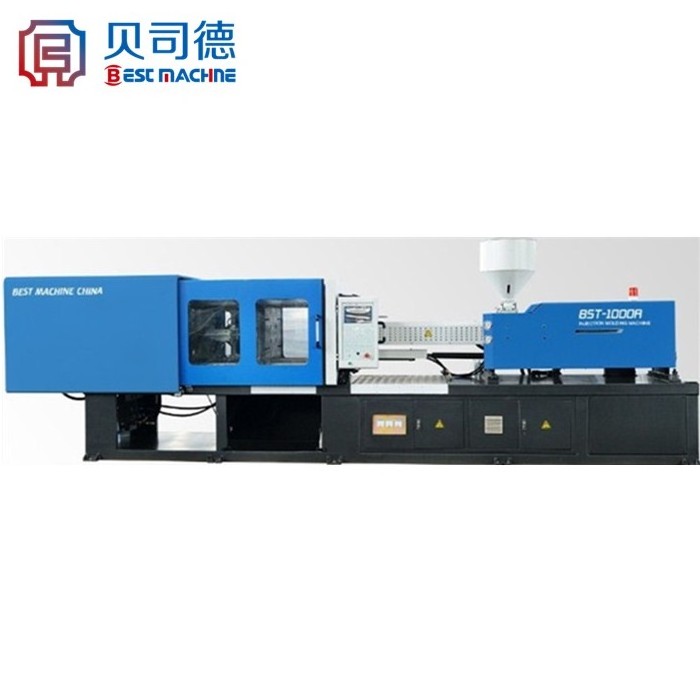

Model Number:

-

BST-1000A

-

Brand Name:

-

BEST Machine

-

Power (kW):

-

18.6 kW

-

Product name:

-

Chinese Mini High Plastic Water Taps

-

Injection pressure:

-

183 Mpa

-

Mould thickness:

-

150-400 mm

-

Ejector tonnage:

-

50 KN

-

Ejector number:

-

5 PieceS

-

Hole diameter:

-

100 mm

-

Max pump pressure:

-

16 Mpa

-

Machine dimension:

-

4.3*1.5*1.6 m

-

Machine weight:

-

3.4 t

-

Oil tank capacity:

-

180 L

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

385mm

-

Distance between Tie Bars(Height)(mm):

-

350mm

-

Plasticizing Capacity(g/s):

-

98

-

Mold Height(mm):

-

150 - 400 mm

-

Ejector Number:

-

5

-

Ejector Stroke(mm):

-

125 mm

-

Ejector Force(kN):

-

50 kN

-

Theoretical Shot Volume(cm³):

-

180 cm³

-

Injection Rate (g/s):

-

98 g/s

-

Injection Weight (g):

-

162 g

-

Screw Speed (rpm):

-

1 - 190 rpm

-

Screw diameter (mm):

-

38 mm

-

Screw L/D Ratio:

-

20.5

-

Distance between Tie Bars:

-

385*350mm

-

Weight (KG):

-

3400 kg

-

Place of Origin:

-

Jiangsu, China

-

Open Stroke(mm):

-

320 mm

-

Model Number:

-

BST-1000A

-

Brand Name:

-

BEST Machine

-

Power (kW):

-

18.6 kW

-

Product name:

-

Chinese Mini High Plastic Water Taps

-

Injection pressure:

-

183 Mpa

-

Mould thickness:

-

150-400 mm

-

Ejector tonnage:

-

50 KN

-

Ejector number:

-

5 PieceS

-

Hole diameter:

-

100 mm

-

Max pump pressure:

-

16 Mpa

-

Machine dimension:

-

4.3*1.5*1.6 m

-

Machine weight:

-

3.4 t

-

Oil tank capacity:

-

180 L

Pictures Of Finished Products Made By Our Machine

The specifications are as follows:

- Imported advanced computer systems, Chinese, English, Russian, Spanish, French, Arabic interface.

- C an save 100 sets of mould parameters.

- Advanced clamping structure and injection parts, precision hydraulic system and circuit design.

- Suitable for producing different types of precision small parts.

- A variety of text can be switched.

- Manual, semi-automatic and fully automatic mode.

- Automatic movement monitoring with alarm and fault diagnosis.

- Function of slope setting can set the start and stop of movements, so as ensure the smooth movement

.

- Quality:12 month Quality guarantee ,Free spare parts replacement,(NOT include man-made sabotage)

- Service:We provide free advanced training and maintenance in china factory,and 24 hours on-line or phone service if you requ e st we also can pro vid e installation and training abroad,until customer's satisf a ction

- Delivery time: 60 days after advance payment

|

MODEL

|

|

BST-1000A

|

|

|||

|

INJECTION UNIT

|

|

A

|

B

|

|||

|

Screw Diameter

|

mm

|

36

|

38

|

|||

|

Shot Size(Theoretical)

|

cm

3

|

143

|

180

|

|||

|

Shot Weight

|

g

|

128

|

162

|

|||

|

Injection Pressure

|

MPa

|

183

|

164

|

|||

|

Injection Rate

|

g/s

|

90

|

98

|

|||

|

Screw L/D Ratio

|

L/D

|

21.6

|

20.5

|

|||

|

Screw Speed

|

r.p.m

|

0-190

|

|

|||

|

Nozzle Diameter

|

srmm

|

10

|

|

|||

|

CLAMPING UNIT

|

|

|

|

|||

|

Clamp Tonnage

|

KN

|

1000KN

|

|

|||

|

Toggle Stroke

|

mm

|

320

|

|

|||

|

Mould Thickness

|

mm

|

150-400

|

|

|||

|

Space Between Tie-bars

|

mm

|

385*350

|

|

|||

|

Ejector Stroke

|

mm

|

125

|

|

|||

|

Ejector Tonnage

|

KN

|

50

|

|

|||

|

Ejector Number

|

Piece

|

5

|

|

|||

|

Hole Diameter

|

mm

|

100

|

|

|||

|

OTHERS

|

|

|

|

|||

|

Heat Power

|

KW

|

7.6

|

|

|||

|

Max. Pump Pressure

|

MPa

|

16

|

|

|||

|

Pump Motor Power

|

KW

|

11

|

|

|||

|

Valve Size

|

mm

|

10

|

|

|||

|

Machine Dimension

|

m

|

4.3*1.5*1.6

|

|

|||

|

Machine Weight

|

T

|

3.4

|

|

|||

|

Oil Tank Capacity

|

L

|

180

|

|

|||