- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

570*580*1503mm

-

Weight (T):

-

7

-

Marketing Type:

-

New Product

-

Nominal force:

-

63KN

-

Stroke of sliding block:

-

35

-

Closed height:

-

150mm

-

Closed height adjustment:

-

30mm

-

Product name:

-

mechanical small punching machine for aluminium profile

-

Packaging Details:

-

Plastic film or according to customer's requirement

-

Machine Function:

-

Punching Ang Press

-

Keyword:

-

press machine

-

Usage:

-

Metal Press

-

Power:

-

750

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

rbqlty

-

Voltage:

-

380V/220V Optional

-

Dimension(L*W*H):

-

570*580*1503mm

-

Weight (T):

-

7

-

Marketing Type:

-

New Product

-

Nominal force:

-

63KN

-

Stroke of sliding block:

-

35

-

Closed height:

-

150mm

-

Closed height adjustment:

-

30mm

-

Product name:

-

mechanical small punching machine for aluminium profile

-

Packaging Details:

-

Plastic film or according to customer's requirement

-

Machine Function:

-

Punching Ang Press

-

Keyword:

-

press machine

-

Usage:

-

Metal Press

-

Power:

-

750

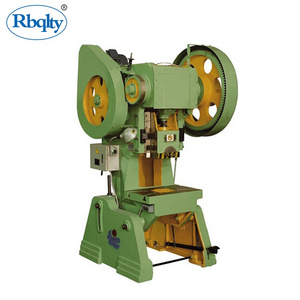

Machine tool equipment mechanical small punching machine for aluminium profile

J23 series

Main Features:

1. J23 series Open Eccentric Presses is a general-purpose presses, suitable for forming, blanking, punching, bending and other cold stamping process.

2. C-frame Casting fuselage,maximum rigidity and minimum deflection for accurate parts and long tool life. body can be tilted, , high rigidity and less deformation Compact. Thick plates and large columns provide you with the stable platform you need for your demanding application.

3. The Machine use Rigid rotated bond clutch rigid and well supported. The clutch gives continuous strokes for mass production.

4. Crank shaft is made of special alloy steel machined to close accuracy and fitted in bronze bushes for smooth working, longer life & accuracy.

5. Properly sized flywheel, is made of high grade cast iron, for storing and releasing adequate energy for the pressing operations, and properly balanced for smooth running.

6. Gear are of steel cast or fabricated. Gear teeth are generated by precision hobbing machine.

7. Machine is with both hands button and foot switch control: anti-tie down, non-repeat controls with ring guards; conforms to OSHA.

8. Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch,easy to operate.

|

Technical Parameters

|

|

Unit

|

J23-6.3

|

J23-10

|

J23-16

|

J23-25

|

J23-40

|

J23-63

|

J23-80

|

|

|

Nominal force

|

|

kN

|

63

|

100

|

160

|

250

|

400

|

630

|

800

|

|

|

Stroke of nominal force

|

|

mm

|

2

|

2

|

2

|

3

|

5

|

5

|

6

|

|

|

Stroke of sliding block

|

|

mm

|

35

|

50

|

60

|

70

|

100

|

100

|

120

|

|

|

Number of strokes

|

|

times/min

|

145

|

130

|

110

|

60

|

55

|

50

|

45

|

|

|

Closed height

|

|

mm

|

150

|

180

|

190

|

210

|

325

|

350

|

370

|

|

|

Closed height adjustment

|

|

mm

|

30

|

35

|

40

|

50

|

65

|

80

|

90

|

|

|

Distance from slider block center to the frame

|

|

mm

|

110

|

130

|

150

|

180

|

250

|

260

|

275

|

|

|

Length between columns

|

|

mm

|

120

|

140

|

160

|

230

|

270

|

310

|

410

|

|

|

Hole size for die handle

|

Diameter

|

mm

|

30

|

35

|

35

|

40

|

50

|

50

|

60

|

|

|

|

Depth

|

mm

|

50

|

50

|

60

|

60

|

70

|

70

|

70

|

|

|

Size of worktable

|

Left-right

|

mm

|

310

|

360

|

440

|

500

|

680

|

720

|

750

|

|

|

|

Front-back

|

mm

|

200

|

240

|

270

|

320

|

460

|

480

|

530

|

|

|

Blanking hole diameter

|

|

mm

|

60

|

80

|

100

|

130

|

150

|

160

|

180

|

|

|

Table plate thickness

|

|

mm

|

30

|

35

|

40

|

50

|

65

|

80

|

100

|

|

|

The max tilt angle

|

|

°

|

45

|

35

|

35

|

30

|

30

|

20

|

20

|

|

|

Left-right

|

|

mm

|

570

|

680

|

730

|

920

|

1060

|

1130

|

1350

|

|

|

Front-back

|

|

mm

|

580

|

630

|

950

|

1180

|

1435

|

1480

|

1715

|

|

|

Height

|

|

mm

|

1503

|

1658

|

1750

|

2040

|

2350

|

2450

|

2670

|

|

|

Power

|

|

kw

|

0.75

|

1.1

|

1.5

|

2.2

|

4

|

5.5

|

7.5

|

|

Motor

Machine regulating screw

Pinion

Pulley

Electrical box

Switch

Lead time

250 ton to 1000 ton 20 to 40 days

Payment Method

irrevocable L/C at sight