Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Qingdao city,China

-

Brand Name:

-

YIERTAI

-

Voltage:

-

380V/3P/50HZ(costomized)

-

Dimension(L*W*H):

-

20m*1.8m*2.0m

-

Power (kW):

-

37

-

Weight:

-

2000 KG

-

Name:

-

PVC Profile Production Line

-

Keywords:

-

Profile Extrusion Machine

-

Usage:

-

window/door/roof/office

-

Final product:

-

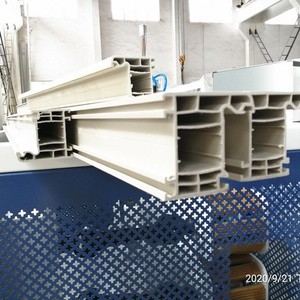

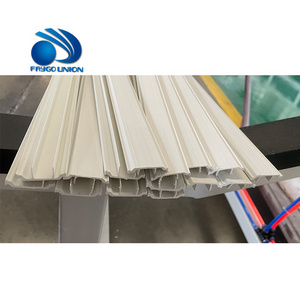

PVC Profile window profile

-

Processing Type:

-

Profile Extrusion machine

-

Extruder:

-

SJSZ Double Screw Extruder

-

Raw material:

-

PVC WPC

-

Product Type:

-

Pvc Sheet profile Extrusion Machine

-

Product name:

-

Profile Making Machine

-

Machine type:

-

PVC WPC Profile Extrusion Machine

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

35 rpm

-

Place of Origin:

-

Qingdao city,China

-

Brand Name:

-

YIERTAI

-

Voltage:

-

380V/3P/50HZ(costomized)

-

Dimension(L*W*H):

-

20m*1.8m*2.0m

-

Power (kW):

-

37

-

Weight:

-

2000 KG

-

Name:

-

PVC Profile Production Line

-

Keywords:

-

Profile Extrusion Machine

-

Usage:

-

window/door/roof/office

-

Final product:

-

PVC Profile window profile

-

Processing Type:

-

Profile Extrusion machine

-

Extruder:

-

SJSZ Double Screw Extruder

-

Raw material:

-

PVC WPC

-

Product Type:

-

Pvc Sheet profile Extrusion Machine

-

Product name:

-

Profile Making Machine

-

Machine type:

-

PVC WPC Profile Extrusion Machine

Product Description

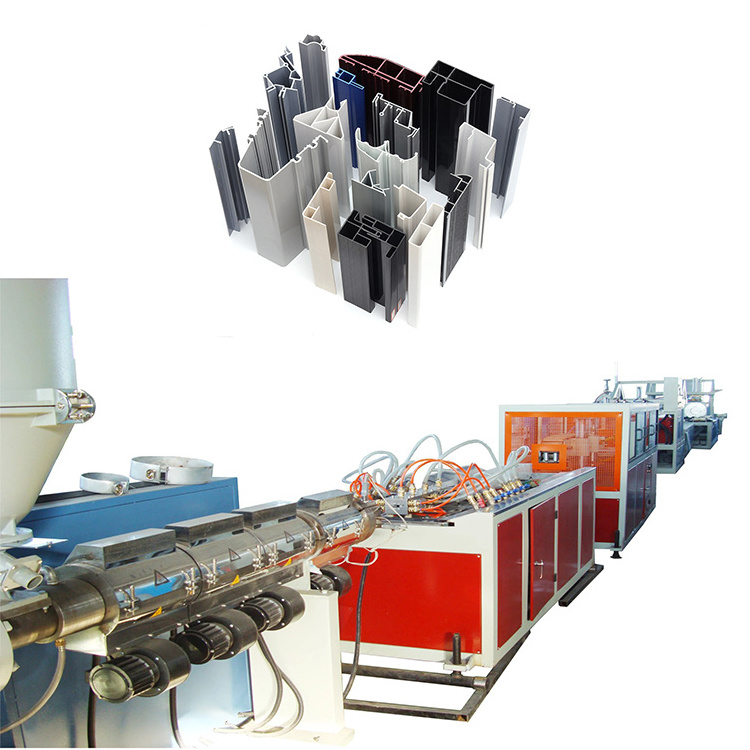

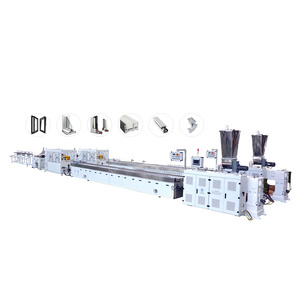

PVC profile extrusion machine

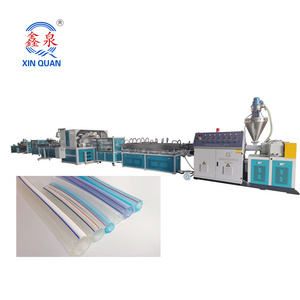

PVC cable trunking production line is mainly used in PVC/WPC profiles ,like window and doors profiles,wood and plastic profiles.

This production line can be according to the different section and mold,selection of different specifications of the double screw extruder,vacuum table,traction,cutting machine and stacker.

Performance characteristics:

1.The whole line has stable operation, high degree of automation, simple operation and low failure rate

2.The automatic feeder has overload protection system and automatic alarm system for shortage of material box

3.According to the differentformula range of customers, using different screw design, to achieve high quality and high efficiency of the stable extrusion process state.

Production Line List

|

NO.

|

Descrption

|

QTY

|

|

1

|

Auto Feeder

|

1 set

|

|

2

|

SJ 65/132 Double Screw Extruder

|

1 set

|

|

3

|

Extrusion die head and mold

|

1 set

|

|

4

|

Calibrating platform

|

1 set

|

|

5

|

Hauling off machine

|

1 set

|

|

6

|

Cutting machine

|

1 set

|

|

7

|

Stacker

|

1 set

|

Crafts Flowing Chart:

Raw materials→ Loader→ Extruder→ Extrusion Mould→ Vacuum sizing → On-line hot stamping machine → Hauling off machine→ Cutter→Stacker

Application

The products are sealed and waterproof, corrosion resistance, wear resistance, longer life, mainly used in bridge engineering,

Chemical thermal electric, gas industry

water pipe line, gas equipment, petroleum engineering, etc.

Specification

|

Model

|

Products width(mm)

|

Drawing speed(m/s)

|

Auxiliary equipment power(kw)

|

Capacity(Kg/H)

|

|

YF-50

|

50

|

0-5

|

18

|

50-80

|

|

YF-108

|

108

|

0-5

|

26

|

80-100

|

|

YF-180

|

180

|

0-5

|

35

|

100-150

|

|

YF-240

|

240

|

0-5

|

35

|

150-200

|

|

YF-300

|

300

|

0-5

|

35

|

150-200

|

|

YF-600

|

600

|

0-3

|

40

|

300-350

|

|

YF-900

|

900

|

0-2.5

|

40

|

350-400

|

|

YF-1200

|

1200

|

0-2.5

|

45

|

400-500

|

Detailed images

Conical twin-screw extruder

Conical twin-screw extruder has special designed screw and mould structure to protect the screw and barrel from easy-abrasion and ensures an easy operation process.

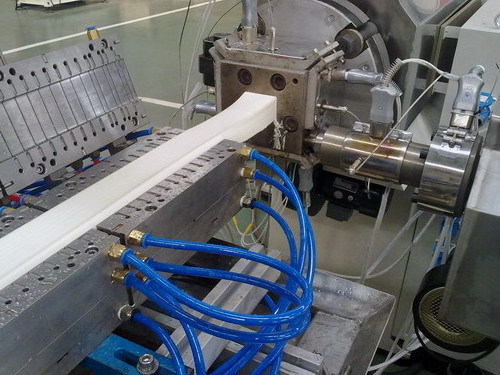

Extrusion die head and mold

Our advantage:vacuum forming mould,connect water for cooling the product.make the product more beautiful and sizing more better quality.

Calibrater and cooling platform

The cooling system has applied special design. The heat emission area is enlarged, the cooling is rapid, and temperature control tolerance can be ± 1 degree.

Vacuum calibration table structure adopt 304# Materia.There is also table up & down motor and forward & back motor,It is all automatic.It is easy to adjust the mold with Vacuum table. All material what touch with water ,we all use stainless steel.

Haul-off Machine

Haul-off Machine: Rubber block is soft material. Adopt best design,it can press products closed,and delivery stably.We choose Geax motor,and control two sets motor by ABB inverter,this mean confirm the two arm run with precise.

Cutting Machine

Cutting Machine control by PLC,we can cutting by meter.We provide different saw to cut different material products,we also have two kind of cutter.One is saw cutter,another one is no-dust cutter(cutting by knife).

Most important,we also can confirm some special products cutting accuracy.

Most important,we also can confirm some special products cutting accuracy.

Auto Stacker

Length: 6 metermaterial: stainless steelEquipped with length limit switch

Automatic stacking

Automatic stacking

Hot Searches