More than 50 years of overseas HVAC project experience,we have successfully completed hundreds of large-scale HVAC projects and have a deep understanding of global HVAC projects.

- Product Details

- {{item.text}}

Quick Details

-

App-Controlled:

-

Yes

-

Fixed Frequency/Variable Frequency:

-

Variable frequency

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Midea

-

Model Number:

-

V8-0517

-

COP:

-

aire acondicionado

-

Power (W):

-

aire acondicionado

-

Voltage (V):

-

380~415V

-

Maximum Airflow Rate:

-

aire acondicionado

-

Featured Function:

-

aire acondicionado

-

Recommended Room Size(square feet):

-

aire acondicionado

-

Product name:

-

Midea hvac systems vrf central air conditioners

-

Power supply:

-

380-415V/3Ph/50Hz

-

Cooling capacity:

-

25.2KW-303KW

-

Power input:

-

5.3-106.2kw

-

Airflow rate:

-

12600-87000m3/h

-

Sound pressure level:

-

56-70dB(A)

-

Fan motors type:

-

DC

-

Compressor type:

-

DC inverter

-

Refrigerant type:

-

R410A

Quick Details

-

Warranty:

-

1 Year

-

Type:

-

Central Air Conditioners

-

Application:

-

Hotel, Outdoor, Garage, Commercial, Household, Manufacturing Facilities, Small Food Stores, Churches, Shopping Malls (Retail Stores), Ice Machines and Manufacturing Plants, Computer Equipment Facilities, Food Storage Facilities, Cold Storage Warehouse, Semiconductor and Assembly and Testing chiller pla, Electronics Manufactures, Airports, Power Plant chillers, Steel Manufacture, Food Industry, Textile Factory, Motor Factory, Printed Circuit Board Manufactures

-

App-Controlled:

-

Yes

-

Fixed Frequency/Variable Frequency:

-

Variable frequency

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Midea

-

Model Number:

-

V8-0517

-

COP:

-

aire acondicionado

-

Power (W):

-

aire acondicionado

-

Voltage (V):

-

380~415V

-

Maximum Airflow Rate:

-

aire acondicionado

-

Featured Function:

-

aire acondicionado

-

Recommended Room Size(square feet):

-

aire acondicionado

-

Product name:

-

Midea hvac systems vrf central air conditioners

-

Power supply:

-

380-415V/3Ph/50Hz

-

Cooling capacity:

-

25.2KW-303KW

-

Power input:

-

5.3-106.2kw

-

Airflow rate:

-

12600-87000m3/h

-

Sound pressure level:

-

56-70dB(A)

-

Fan motors type:

-

DC

-

Compressor type:

-

DC inverter

-

Refrigerant type:

-

R410A

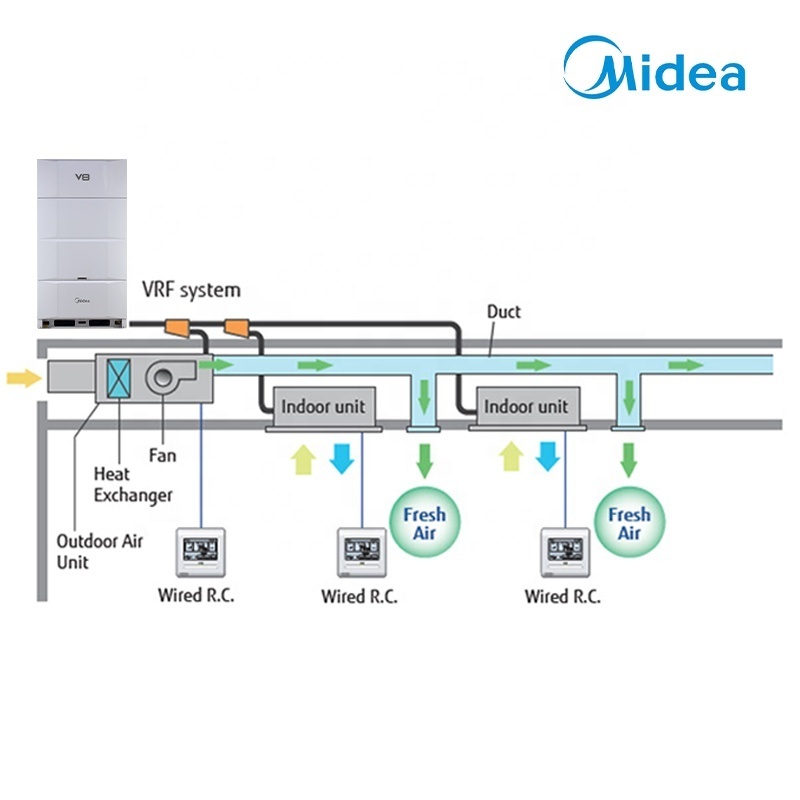

Midea VRF is a powerful system for your next HVAC project if you are looking for cost effective solutions.

Midea HVAC provides one-stop service, including VRF drawing design, model selection, installation material calculation, start up guidance etc, equipment, supplying installation material and other parts directly for your project which makes your VRF projects easier.

Why Choose Us

1.Experience

2.Professional design

Our professional design team are ready to provide you a AC plan drawing based on your architecture blueprint. in this case, you do not need to find an engineering advisor to design the HVAC layout. Save both time & money for you !

3.Professional selectoion

Based on Midea diversified commercial air conditioning system, we can select the most suitable model for your project according to the drawings.

4.Providing One-Stop Solution of HVAC System

One-stop service helps save cost and time. Generally including air conditioning Indoor units and outdoor units, control system, installing accessories(refrigerant copper pipe, UPVC pipes, rubber insulation, hoist,brackets, communication wire etc), refrigerant tools(vacuum pump, cutter,expansion tools etc), ventilation grill & diffuser etc.

5.Technical Support

HVAC commissioning service can be provided accordingly. Air conditioner project engineers can guide and supervise product installation on site.

6.After-sales service

We have Global After-Sales System with expertise service. Ensure your after-sales worry-free.

How to get a quick quotation?

Information needed by Midea Group’s management system before prepare quotation details for you.

1.Project Drawing, building layout, equipment BOQ.

2.Project name: building name or building type, such as xxx office project, residential house project etc.

3.Expected shipping date of this project.

4.Project type: tender or self-owned.

Product Line

|

Product name

|

|

Midea V8 Series VRF System Central Air Conditioner

|

|

|

|||

|

Power Supply

|

|

380-415/3/50(60)

|

|

|

|||

|

Cooling1

|

Capacity

|

25.2KW-303KW

|

86-1033.8KBtu/h

|

|

|||

|

|

Power input

|

5.3-106.2KW

|

|

|

|||

|

|

EER

|

4.76-2.85KW/KW

|

|

|

|||

|

Heating2

|

Capacity

|

27KW-330KW

|

92.1-1013.4KBtu/h

|

|

|||

|

|

Power input

|

5.4-104.1KW

|

|

|

|||

|

|

COP

|

5.03-3.23KW/KW

|

|

|

|||

|

Compressors

|

Type

|

DC inverter

|

|

|

|||

|

Fan motors

|

Type

|

DC

|

|

|

|||

|

|

Max.ESP

|

0-20 (standard)

20-120 (customized) (Pa) |

|

|

|||

|

|

Airflow rate

|

12600-87000m3/h

|

|

|

|||

|

Refrigerant

|

Type

|

R410A

|

|

|

|||

|

Ambient temp

|

Cooling

|

-15℃ to 55 ℃

|

|

|

|||

|

|

Heating

|

-30 to 30℃

|

|

|

|||

The V8 Series VRF uses a variety of algorithms and self-learning technology to monitor the operation of the equipment through operating parame-ters and timely maintenance, so that the equipment always runs in opti-mal condition throughout its life cycle

HyperLink

Midea original communication bus chip greatly simplifies installation and saves installation cost

HyperLink communication technology supports any wiring pattern rather than just daisy chain

connection, reducing the installation cost and the possibility of incorrect connection. It has

stronger anti-interference ability, achieving communication distance up to 2000m.

connection, reducing the installation cost and the possibility of incorrect connection. It has

stronger anti-interference ability, achieving communication distance up to 2000m.

Arbitrary Topology Communication

In addition to the traditional daisy chain connection, the communication wire supports tree connection, star connection, ring connection and so on. The wring is flexible, which greatly reduces the installation cost and has no possibility of wrong connection on site.

Super Anti-interference Capability

Special waveform restoration technology enhances anti-interference performance for more stable communication.

Flexible Power Supply for Indoor Units

HyerLink 's unique communication method

allows the indoor units to be powered not only

by a uniform power supply, but also by

individual and zone power supplies, making it

particularly suitable for each shop in a large

complex building, which can independently

power on and off its own indoor units.

allows the indoor units to be powered not only

by a uniform power supply, but also by

individual and zone power supplies, making it

particularly suitable for each shop in a large

complex building, which can independently

power on and off its own indoor units.

ShieldBox

IP55 fully enclosed electric control box provides all-round protection for internal electronic

components, greatly improving system RELIABILITY

components, greatly improving system RELIABILITY

Fully enclosed electronic components are isolated from the external environment to protect against

corrosion, sand, humidity, snowstorm and other harsh conditions, and prevent small animals and

insects from entering the chamber. To provide comprehensive protection for internal electronic

devices, improve the overall environmental tolerance.

insects from entering the chamber. To provide comprehensive protection for internal electronic

devices, improve the overall environmental tolerance.

All Microchannel Refrigerant Cooling

All electronic components including inverter

module, filter module and power module are cooled

by specially designed microchannel refrigerant to

ensure that the electronic components work in the

best temperature range.

module, filter module and power module are cooled

by specially designed microchannel refrigerant to

ensure that the electronic components work in the

best temperature range.

PTC Heater

The unique PTC heater, with precise temperature control

sensor, can still ensure that the temperature inside the

chamber is within the normal operating temperature

range of electronic devices even in the low-temperature

environment of -30°C.

sensor, can still ensure that the temperature inside the

chamber is within the normal operating temperature

range of electronic devices even in the low-temperature

environment of -30°C.

Built-in Circulating Fan

The built-in circulating fan accelerates the air flow

inside the chamber, and the heat exchange is more

sufficient to ensure the consistent ambient

temperature inside the chamber.

inside the chamber, and the heat exchange is more

sufficient to ensure the consistent ambient

temperature inside the chamber.

5 High Precision Temperature Sensors

5 high precision temperature sensors are used to

accurately monitor the operation state of electronic

control under various conditions to ensure that the

internal temperature of the chamber is always kept within a stable range.

accurately monitor the operation state of electronic

control under various conditions to ensure that the

internal temperature of the chamber is always kept within a stable range.

SuperSense

The status of the refrigerant is known anywhere throughout the process, ensuring high RELIABILITY

and COMFORT.

and COMFORT.

Up to 19 sensors are distributed throughout the refrigerant system, and the status of the

refrigerant is known anywhere throughout the process, ensuring stable operation. At the same

time, combined with the digital twin technology of the refrigerant system, a virtual sensor can be

created in the event of a physical sensor failure, so that the system does not shut down in the

event of a sensor failure, ensuring comfort.

refrigerant is known anywhere throughout the process, ensuring stable operation. At the same

time, combined with the digital twin technology of the refrigerant system, a virtual sensor can be

created in the event of a physical sensor failure, so that the system does not shut down in the

event of a sensor failure, ensuring comfort.

Complete Sensors

The V8 Series VRF has the industry's most

comprehensive range of 19 condition sensors with

built-in data models for compressors, heat

exchangers, throttling components and more. By

analyzing sensor data in real time, it can sense the

status of the refrigerant anywhere in the system.

comprehensive range of 19 condition sensors with

built-in data models for compressors, heat

exchangers, throttling components and more. By

analyzing sensor data in real time, it can sense the

status of the refrigerant anywhere in the system.

Refrigerant Amount Diagnosis*

Thanks to the complete sensors, the refrigerant running state is clearly visible, so as to accurately diagnose the amount of refrigerant.

In the event of a sensor failure, other sensors can automatically simulate a virtual backup sensor, so that the VRF system can continue to operate without stopping.

Midea ETA (META) 2.0

META is the abbreviation of Midea Evaporating Temperature Alteration

Further upgraded META technology to maximize ENERGY SAVING.

Further upgraded META technology to maximize ENERGY SAVING.

Built-in professional operation and maintenance algorithm, so that the annual operation energy

efficiency of each set of systems increased by more than 28%.

efficiency of each set of systems increased by more than 28%.

Hot Searches