- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V, can be customized

-

Dimension(L*W*H):

-

according to model

-

Weight:

-

15000 KG

-

Color:

-

Customizable

-

Application:

-

Gold, copper, iron, lead zinc, etc

-

beneficiation method:

-

gravity, flotation, megnetic separation

-

Capacity:

-

1-50t/h

-

Installation:

-

Technical Guidance

-

Usage:

-

Mining Crushing

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Certification:

-

ISO, CE

-

Advantage:

-

High Separation Efficiency

-

Feature:

-

High Recovery Rate Easy

Quick Details

-

Production Capacity:

-

99%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FTL

-

Voltage:

-

380V, can be customized

-

Dimension(L*W*H):

-

according to model

-

Weight:

-

15000 KG

-

Color:

-

Customizable

-

Application:

-

Gold, copper, iron, lead zinc, etc

-

beneficiation method:

-

gravity, flotation, megnetic separation

-

Capacity:

-

1-50t/h

-

Installation:

-

Technical Guidance

-

Usage:

-

Mining Crushing

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Certification:

-

ISO, CE

-

Advantage:

-

High Separation Efficiency

-

Feature:

-

High Recovery Rate Easy

FTL Mineral Processing Machine For Manganese Zinc Lead Copper Chrome Nickel Lithium Ore Beneficiation Plant

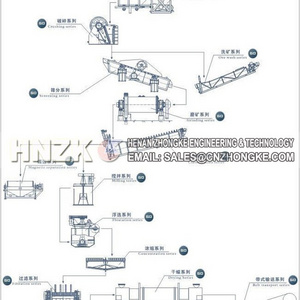

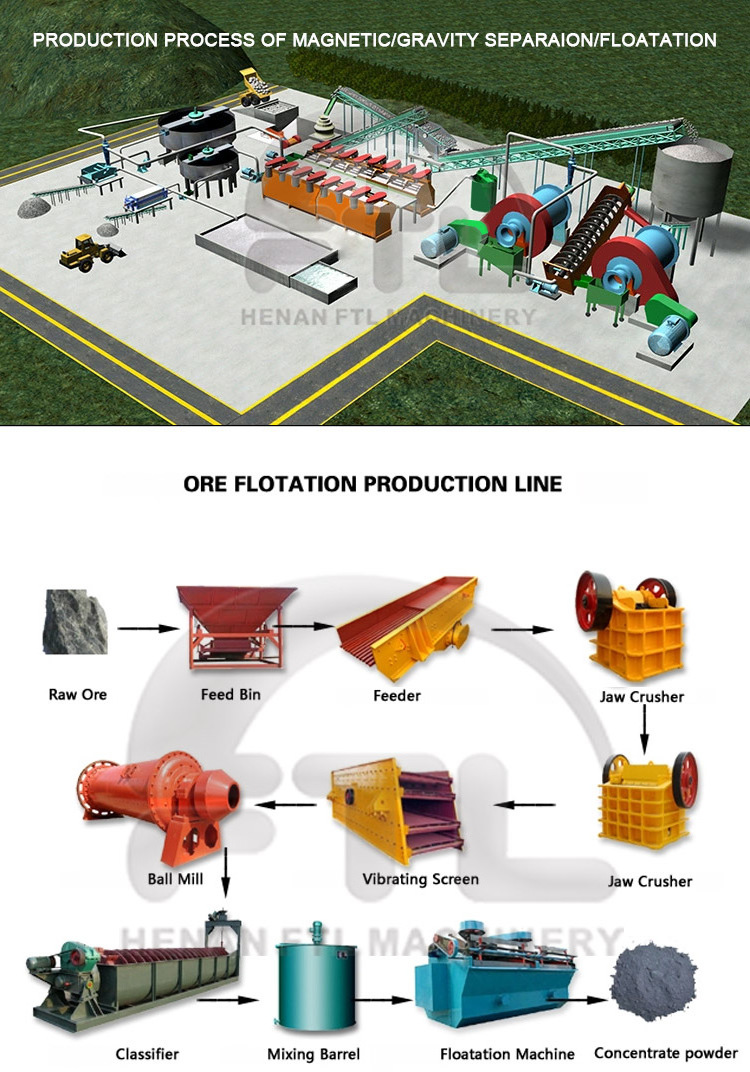

BENEFICIATION PROCESSING PLANT

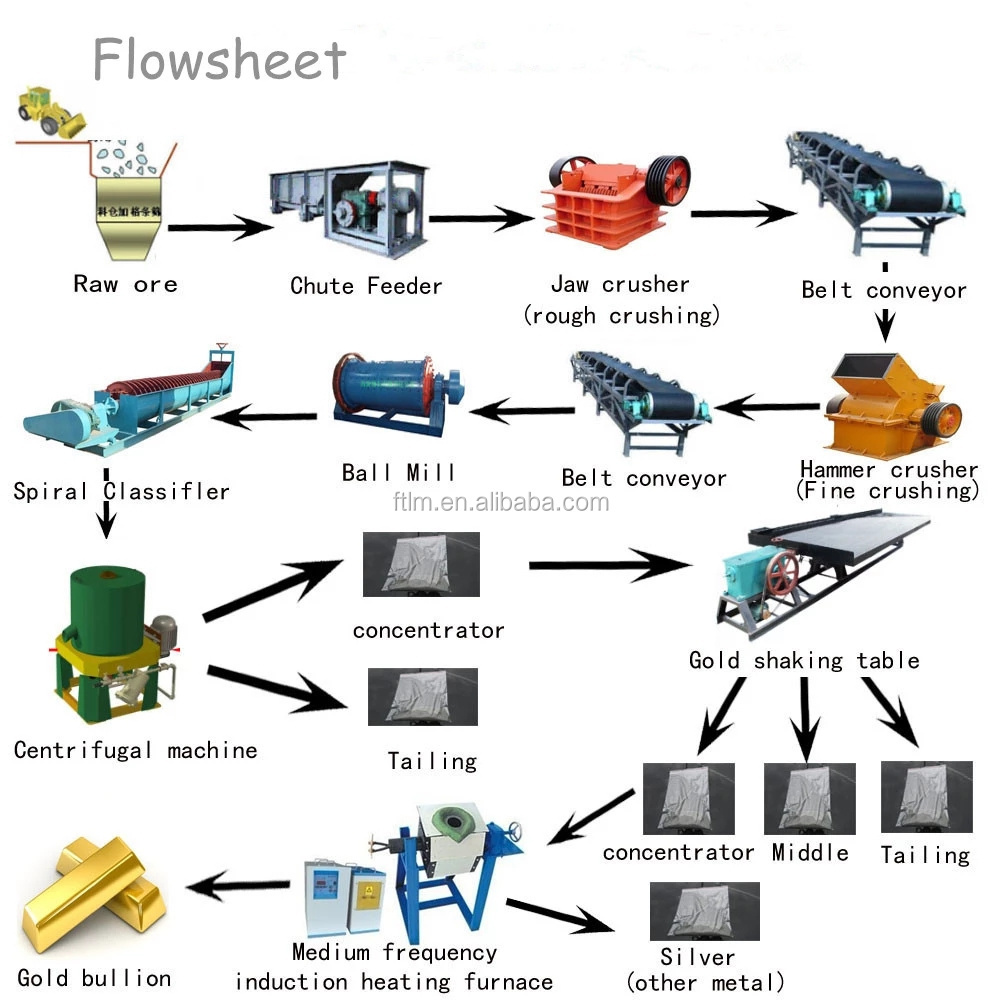

According to the differences of physical and chemical properties of gold ore surface, gold ore flotation production line is treated by flotation reagents, the gold deposits are selectively stick to the bubbles for the purpose of separation.

Gold flotation process is divided into several parts, such as crushing, grinding and flotation etc.It will be used jaw crusher, ball mill, spiral classifier, flotation machine, the mixing tank, thickener and other equipment.

APPLICATION SCOPE

Vein gold ore; Sulfide gold ore.In addition to separate gold, the process can also be used for flotation of copper ore, lead and zinc ore, fluorite ore, feldspar ore, graphite ore, tungsten ore and other metals and non-metal ore.

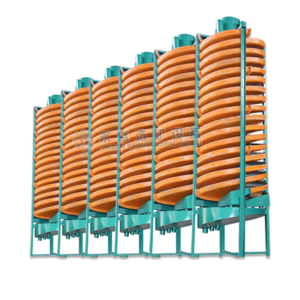

ORE GRAVITY PROCESSING

Gravity separation process is the use of mineral density and particle size differences, with the help of the dielectric fluid and all kinds of mechanical force combined to cause appropriate loose layer and separation conditions, in order to gain the technological process of different density and different particle size of products

APPLICATION SCOPE

It is mainly used for the treatment of alluvial gold, as well as in combination with other types of mineral processing techniques.

In addition to deal with gold processing, it can also be used for processing tungsten ore, tin ore, manganese ore, titanium ore, tantalum niobium ore, barite, Iron pyrite, antimony, chrome ore, etc.

| Application | gold ore, copper ore, iron, lead zinc, manganess.... |

| capacity | 1~120t/h |

| processing method | gravity, flotation, magnetic separation process |

Main equipment used in the ore beneficiation plant